Method for rapidly preparing micron-sized carbon sphere with good dispersibility

A micron-scale, dispersive technology, applied in the field of adsorption materials, can solve the problems of strong corrosiveness and easy damage to the spherical structure of HTCS, and achieve the effect of excellent performance, maintaining the shape unchanged, and low temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example involves the rapid preparation of highly dispersible HTCS, potassium oxalate non-destructive activation of HTCS to prepare ACS, and a comparative experiment, the specific steps include:

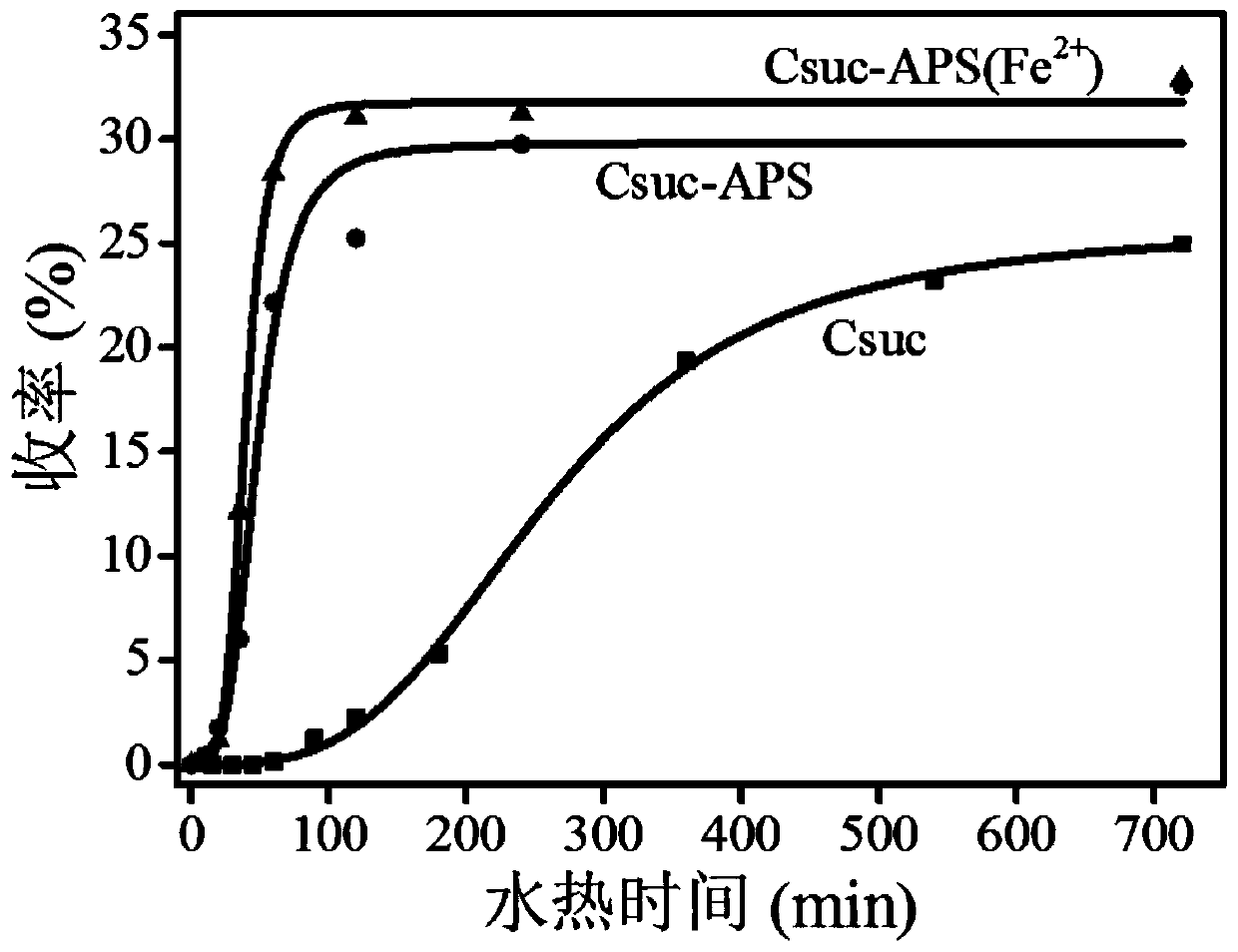

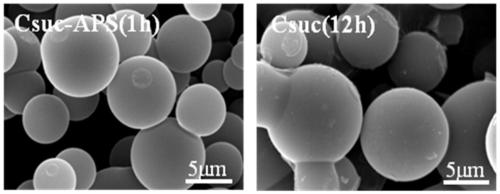

[0049] Sample (1): Dissolve 6 parts by mass of sucrose and 1 part by mass of APS in 40 parts by volume of water, then transfer the mixed solution to 80 parts by volume of a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and place it in a hot air oven The temperature was raised to 75°C for 2 hours, and then heated to 180°C for 2 hours. The reaction solution was filtered, the filter cake was washed three times with water and ethanol, and the filter cake was dried at 80°C in a hot air oven for 8 hours to obtain 1.62 parts by mass of black fluffy powder. , named Csuc-APS(2h).

[0050] Sample (2): Dissolve 6 parts by mass of sucrose in 40 parts by volume of water, then transfer the solution to 80 parts by volume of a stainless steel hydrothermal kettle ...

Embodiment 2

[0054] This example involves the rapid preparation of highly dispersible HTCS, potassium oxalate non-destructive activation of HTCS to prepare ACS, and a comparative experiment, the specific steps include:

[0055] Sample (1): Dissolve 6 parts by mass of sucrose and 1 part by mass of APS in 40 parts by volume of water, then add 0.1M FeSO 4 0.5 parts by volume of the solution, and then transfer the mixed solution to 80 parts by volume of a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, place it in an oven and heat it up to 75°C and keep it warm for 4h, then heat it up to 180°C and keep it warm for 1h. The reaction solution was filtered, the filter cake was washed three times with water and ethanol respectively, and the filter cake was baked in a hot air oven at 80° C. for 8 hours to obtain 1.86 parts by mass of a black fluffy powder, named Csuc-APS (Fe 2+ )(1h).

[0056] Sample (2): Dissolve 6 parts by mass of sucrose in 40 parts by volume of water, th...

Embodiment 3

[0061] This example involves the rapid preparation of highly dispersible HTCS, potassium oxalate non-destructive activation of HTCS to prepare ACS, and a comparative experiment, the specific steps include:

[0062] Sample (1): Dissolve 6 parts by mass of sucrose and 5 parts by mass of APS in 40 parts by volume of water, then add 0.1M FeSO 4 solution 1.5mL, and then transfer the mixed solution into 80 parts by volume of a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, place it in an oven and raise the temperature to 75°C and keep it warm for 4h, then raise the temperature to 185°C and keep it warm for 2h. The liquid was filtered, the filter cake was washed three times with water and ethanol respectively, and the filter cake was dried in a hot air oven at 80°C for 8h to obtain 2.12 parts by mass of a black fluffy powder, which was named as Csuc-APS(Fe 2+ )(2h);

[0063] Sample (2): Dissolve 6 parts by mass of sucrose in 40 parts by volume of water, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com