Catalyst for preparing methyl isobutyl ketone by one-step method of acetone, preparation method and application thereof

A technology of methyl isobutyl ketone and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost and poor catalyst activity. , to achieve the effect of strong adaptability, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

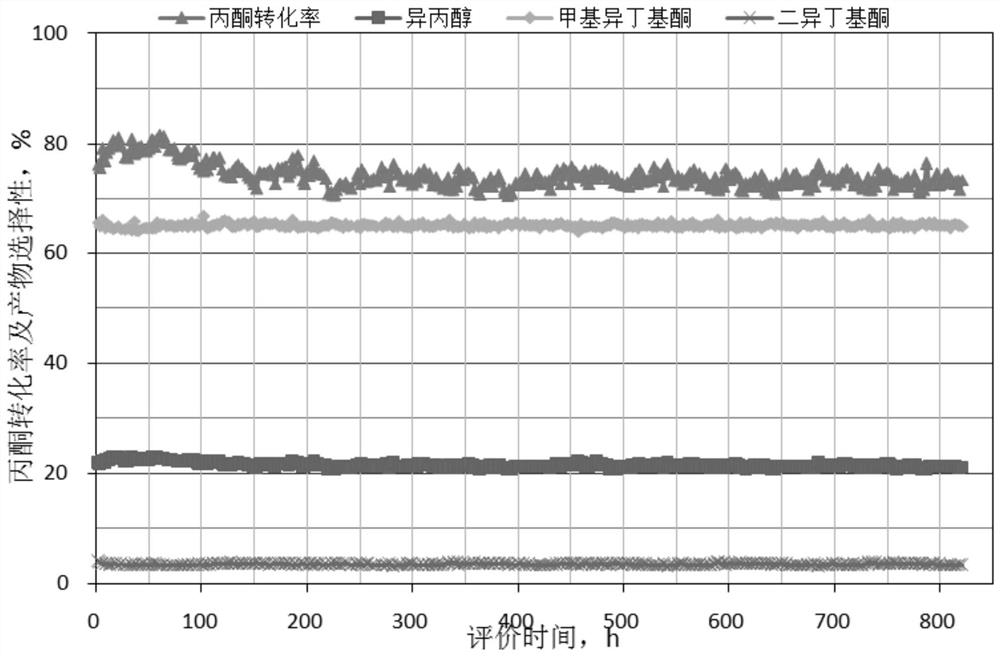

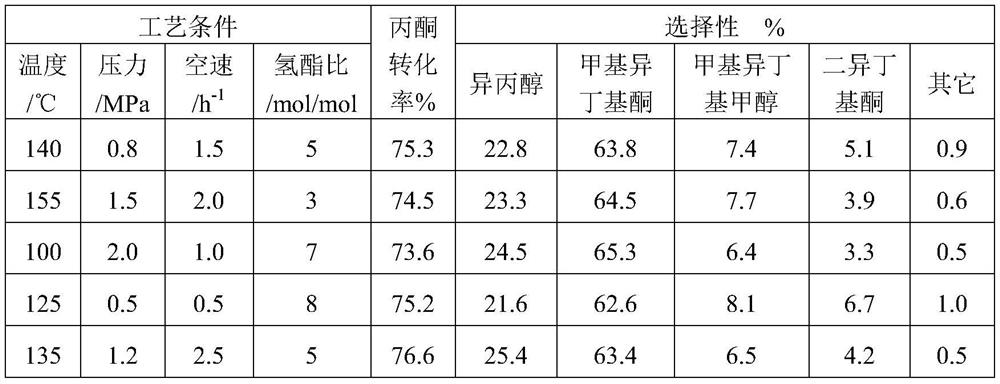

Examples

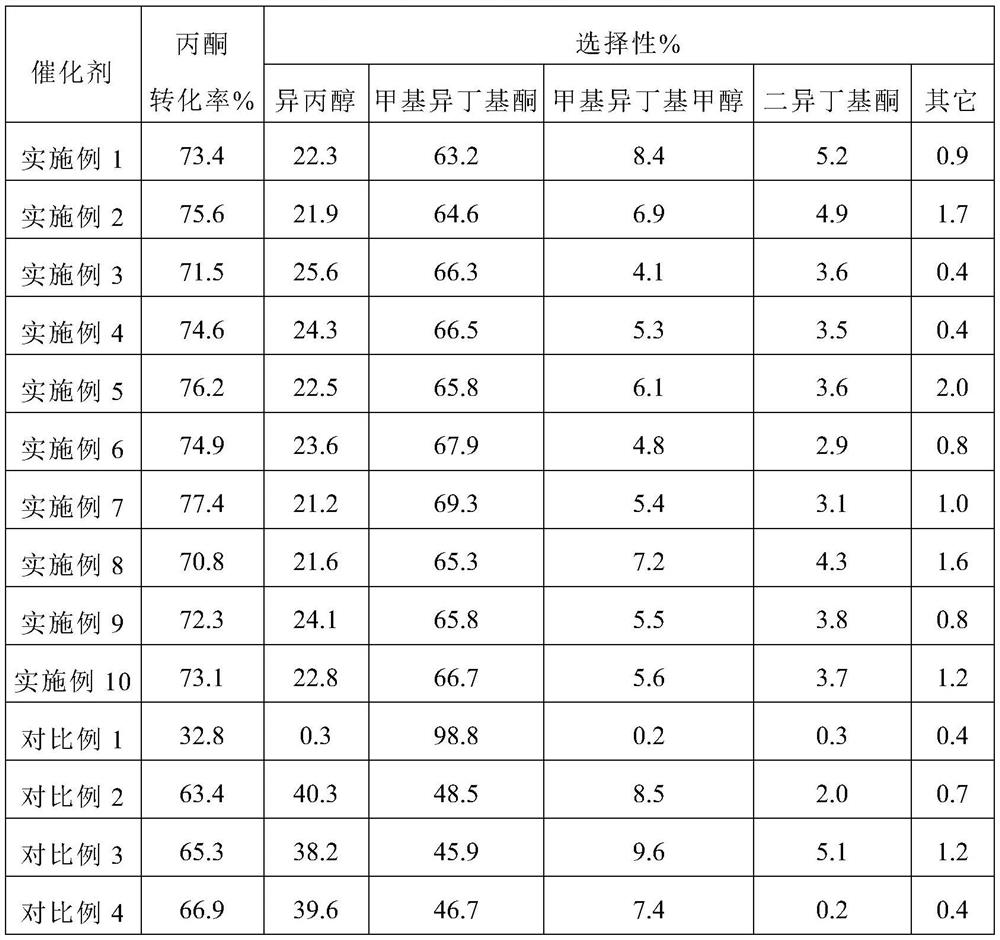

Embodiment 1

[0041] Dissolve 30g of nano-titanium dioxide in 20mL of ethanol to make mixture I, weigh 115g of alumina powder, add 5g of turnip powder and 10g of citric acid and mix well to make mixture II, add mixtures I and II to the kneader Mix evenly, and add 6.0mL of dilute nitric acid and 65mL of water to stir and knead to form, and the obtained carrier is dried and roasted at 1050°C to obtain a titanium-modified carrier; 19.5g of copper nitrate and 0.16g of palladium chloride are weighed and dissolved in Impregnate 95g of the carrier prepared above with equal volume of 30mL water, dry at 120°C for 2h after impregnation, decompose at 350°C for 3h, then reduce the catalyst with a mixture of 5vol% hydrogen and 95vol% nitrogen according to the temperature program, and raise the temperature to 280°C After constant temperature reduction for 4 hours, the catalyst was obtained after cooling down. According to X-fluorescence test and analysis, the catalyst contained 3.85 parts of copper, 0.62 ...

Embodiment 2

[0043] Dissolve 20.4g of nano-titanium dioxide in 15mL of isopropanol to make mixture I, weigh 25g of silicon dioxide and 100g of alumina powder and add 6g of turnip powder and 12g of citric acid and mix well to make mixture II. Mixing materials I and II were added to a kneader and mixed evenly, and 3.5mL of dilute sulfuric acid and 70mL of water were added to stir and knead to shape, and the obtained carrier was dried and roasted at 970°C to obtain a titanium-modified carrier; weigh 20g of copper nitrate and Dissolve 0.15g of palladium chloride in 36mL of water and impregnate 95g of the above-prepared carrier in equal volume. After impregnation, dry at 100°C for 2h, decompose at 380°C for 3h, and then use a mixed gas of 5vol% hydrogen and 95vol% nitrogen according to the temperature program method. Reduce the catalyst, raise the temperature to 270°C and reduce it at a constant temperature for 4 hours. After cooling down, the catalyst is prepared. According to X-fluorescence te...

Embodiment 3

[0045] Dissolve 10.8g of butyl titanate in 12mL of ethanol to make a mixture I, weigh 75g of silicon dioxide and 55g of alumina powder, add 8g of turnip powder and 10g of citric acid and mix well to make a mixture II, Mix materials I and II into a kneader and mix them evenly, and then add 7.5mL of dilute nitric acid and 77mL of water to stir and knead to form the obtained carrier. After drying and roasting at 1150°C, a titanium-modified carrier is obtained; weigh 9.1g of copper nitrate Dissolve 0.1g of palladium chloride in 25mL of water and impregnate 95g of the above-prepared carrier in equal volume. After impregnation, dry at 110°C for 2h, decompose at 350°C for 3h, and then use a mixture of 5vol% hydrogen and 95vol% nitrogen according to the temperature program method. Gas reduction catalyst, heating up to 240°C and constant temperature reduction for 6 hours, the catalyst was prepared after cooling down, and analyzed by X-fluorescence test, the catalyst was 1.59 parts of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com