High tear resistance fluorosilicone rubber composition and preparation method thereof

A fluorosilicone rubber and tearing performance technology, applied in the rubber field, can solve the problems of easy structuring, difficult mixing of 4# fumed silica, and flying, etc., to improve the molding rate and excellent tear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

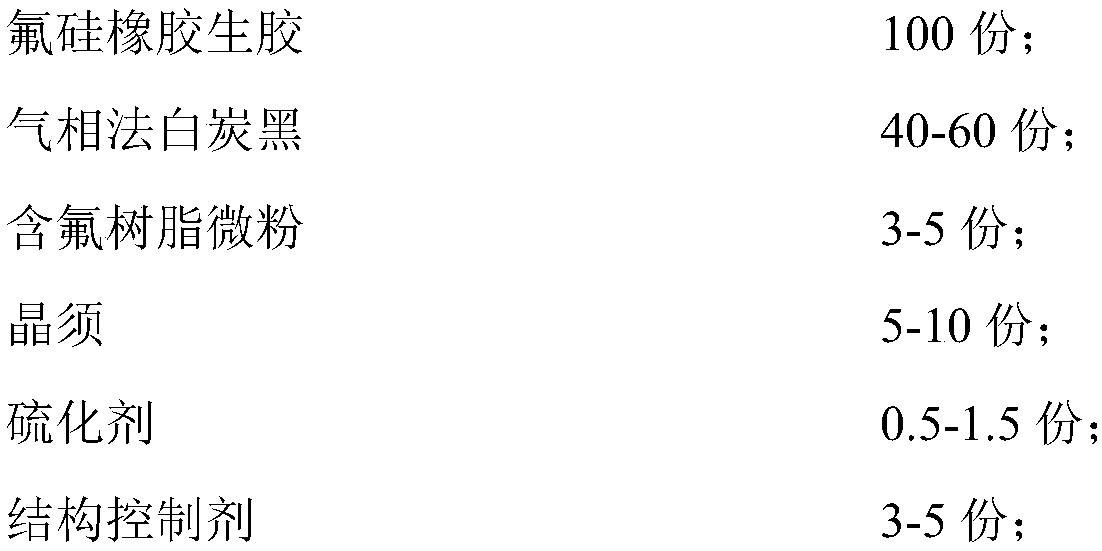

[0038] The high tear-resistant fluorosilicone rubber composition has the following raw material parts by mass: 100 parts of raw fluorosilicone rubber with a molecular weight of 800,000 and a molecular weight distribution of 1.8; 40 parts of fumed silica with a specific surface area of 200; 3 parts of tetrafluoroethylene micropowder with a particle size of 25 microns; potassium titanate whiskers in ceramic whiskers are used as whiskers, with a diameter of 0.3 microns and a length of 10 microns, and the usage amount is 5 parts; the main vulcanizing agent is 2,5 - 0.8 part of dimethyl-2,5-di-tert-butyl peroxide hexane, 0.1 part of secondary vulcanizing agent 2,4-dichlorobenzoyl peroxide; 3 parts of structure control agent 100cp hydroxyfluorosilicone oil.

[0039] The preparation method is as follows:

[0040] 1) Add fluorosilicone rubber raw rubber, fumed silica, fluorine-containing resin micropowder, whiskers, and structure control agent in parts by mass to the internal mixer ...

Embodiment 2

[0043] The high-tear-resistant fluorosilicone rubber composition has the following mass parts of raw materials: 100 parts of raw fluorosilicone rubber with a molecular weight of 600,000 and a molecular weight distribution of 1.6; 60 parts of fumed silica with a specific surface area of 100; 5 parts of polyvinylidene fluoride micropowder with a particle size of 50 microns; silicon carbide whiskers in ceramic whiskers among inorganic whiskers, 0.4 microns in diameter, 15 microns in length, and 8 parts in dosage for the whiskers; mainly Vulcanizing agent dicumyl peroxide 1.0 parts, secondary vulcanizing agent 2,4-dichlorobenzoyl peroxide 0.1 part; structure control agent 200cp hydroxyfluorosilicone oil 5 parts.

[0044]The preparation method is the same as that of Example 1, except that: in step 1, the mixing temperature is 65° C., and the mixing time is 0.3 hours; heat treatment is performed in an oven at 150° C. for 2 hours; in step 2, thinning is performed 15 times.

Embodiment 3

[0046] The fluorosilicone rubber composition with high tear resistance performance has the following mass parts of raw materials: 100 parts of raw fluorosilicone rubber with a molecular weight of 1 million and a molecular weight distribution of 2.0; 60 parts of fumed silica with a specific surface area of 300 Particle diameter is 4 parts of polytetrafluoroethylene micropowder of 100 microns; Whisker uses the poly(4-hydroxybenzyl ester) whisker in organic whisker, and diameter is 0.6 micron, and length is 20 microns, and usage amount is 10 parts 1.2 parts of main vulcanizing agent di-tert-butyl peroxide, 0.1 part of secondary vulcanizing agent 2,4-dichlorobenzoyl peroxide; 4 parts of structure control agent 80cp hydroxyfluorosilicone oil.

[0047] The preparation method is as shown in Example 1, the difference is that in step 1, the mixing temperature is 70°C, the mixing time is 0.28 hours, and heat treatment is carried out in an oven at 160°C for 3 hours; in step 2, thin pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com