Method for preparing transition metal-doped alkali silicate glass

An alkali silicate, transition metal technology, applied in coatings and other directions, can solve problems such as energy consumption, failure of doped glass, difficult operation, etc., and achieve the effect of controllability and chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Cut commercial soda-lime silicate glass into glass substrates with a size of 100×50×0.7mm, and then perform chamfering, chamfering, polishing, deionized water cleaning and drying, wherein the mass percentage: 72% SiO 2 , 13.5% Na 2 O, 1%K 2 O, 8% CaO, 4% MgO, 1.2% Al 2 o 3 and others.

[0025] (2) Ion exchange treatment: In an automatic tempering furnace, immerse the processed glass substrate in pure potassium nitrate molten salt with a purity greater than or equal to 99.9%, adjust the temperature to 450° C., and perform ion exchange for 8 hours. After K + -Na + The ion-exchanged glass substrates were ultrasonically cleaned with acetone and ethanol solutions, and finally air-dried.

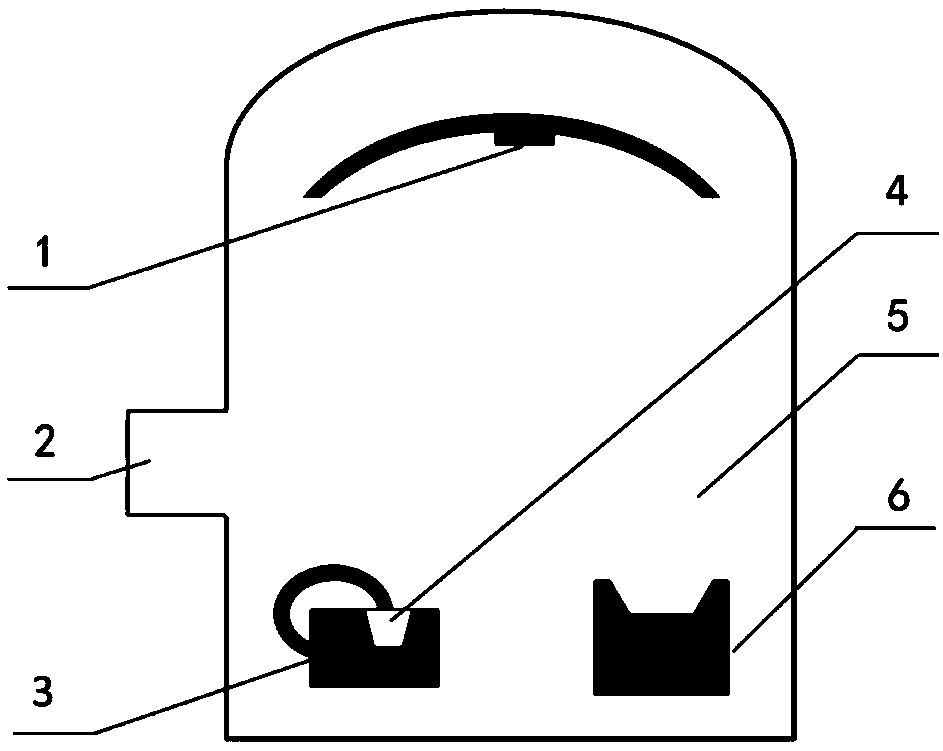

[0026] (3) Doping treatment: put the dried glass substrate into the ZZSX-800F vacuum coating system, such as figure 1 As shown, wherein 1 glass substrate; 2 vacuum pump; 3 electron gun; 4 evaporation source; , heating the glass substrate, passing argon gas into the EH1000 Hall ...

Embodiment 2

[0029] (1) Cut commercial soda-lime silicate glass into glass substrates with a size of 80×40×0.8mm, and then perform chamfering, chamfering, polishing, cleaning and drying with deionized water, wherein the mass percentage: 69% SiO 2 , 15% Na 2 O, 1.14%K 2 O, 6.53% CaO, 5.05% MgO, 1.73% Al 2 o 3 and others.

[0030] (2) Ion exchange treatment: In an automatic tempering furnace, immerse the processed glass substrate in pure potassium nitrate molten salt with a purity greater than or equal to 99.9%, adjust the temperature to 480°C, and perform ion exchange for 20 minutes; after K + -Na + The ion-exchanged glass substrates were ultrasonically cleaned with acetone and ethanol solutions, and finally air-dried.

[0031] (3) Doping treatment: put the dried glass substrate into the CCZK-ION multi-arc ion coating system, add gold particles to be doped with a purity greater than or equal to 99.99% in the plating target, vacuum the vacuum pump, and heat the glass substrate The gla...

Embodiment 3

[0034] (1) Cut commercial soda-lime silicate glass into glass substrates with a size of 100×50×0.8 mm, and then perform chamfering, chamfering, polishing, cleaning and drying with deionized water, 72% SiO 2 , 13.5% Na 2 O, 1%K 2 O, 8% CaO, 4% MgO, 1.2% Al 2 o 3 and others.

[0035] (2) Ion exchange treatment: In an automatic tempering furnace, immerse the processed glass substrate in pure potassium nitrate molten salt with a purity greater than or equal to 99.9%, adjust the temperature to 360°C, and perform ion exchange for 50 hours; after K + -Na + The ion-exchanged glass substrate was ultrasonically cleaned with acetone solution, and finally air-dried.

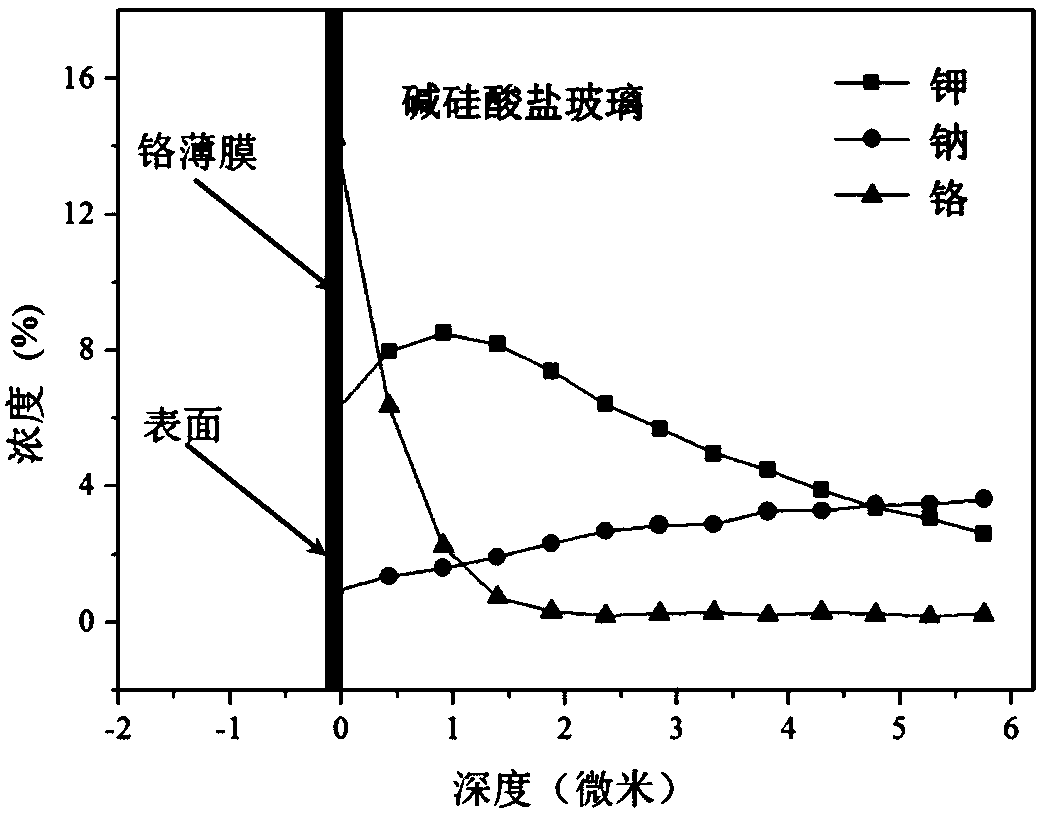

[0036] (3) Doping treatment: put the dried glass substrate into the FJL560D2 ion beam multi-functional sputtering coating system, add a chromium target with a purity greater than or equal to 99.99% to the sputtering target, vacuum the vacuum pump, and heat the glass substrate. The ion beam sputtering method is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com