Processing technology of molded surface of high-strength wear-resistant titanium alloy forging mold

A mold surface and processing technology technology, which is applied in the field of high-strength wear-resistant titanium alloy forging mold surface processing technology, can solve the problems of affecting the service life of the device, long production cycle of forging die, uneven organizational structure, etc., to improve the use of Effects of life, improvement of hardness, and improvement of cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Select the base material of the mold and select 56NiCrMoV7 material.

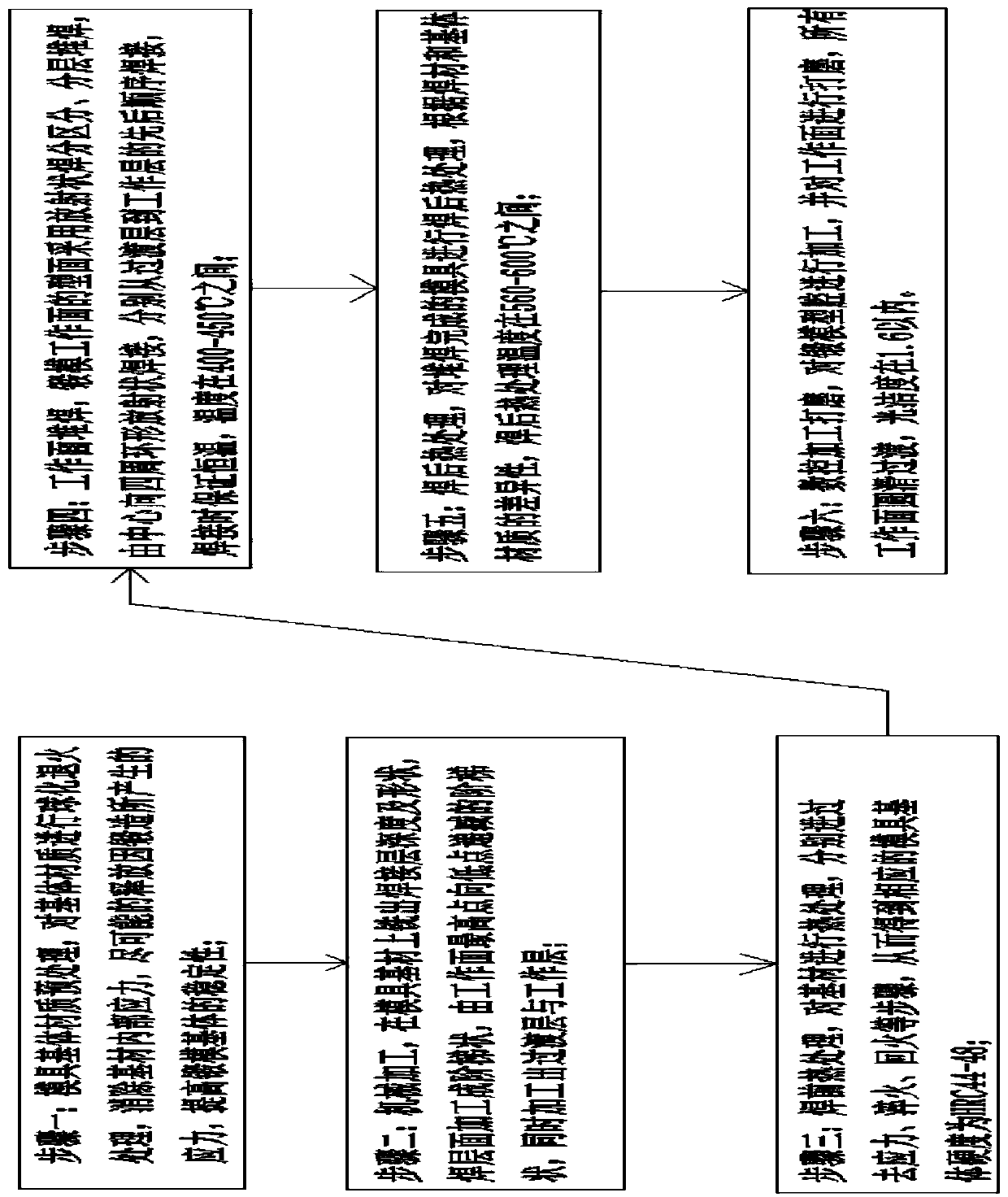

[0045] Step 1: Pretreatment of mold base material

[0046] Carry out spheroidizing annealing treatment on the mold base 100, heat it to 720°C for 4 hours, then slowly cool it to 550°C at a rate of 20°C per hour, and then air cool to room temperature;

[0047] Step 2: Machining

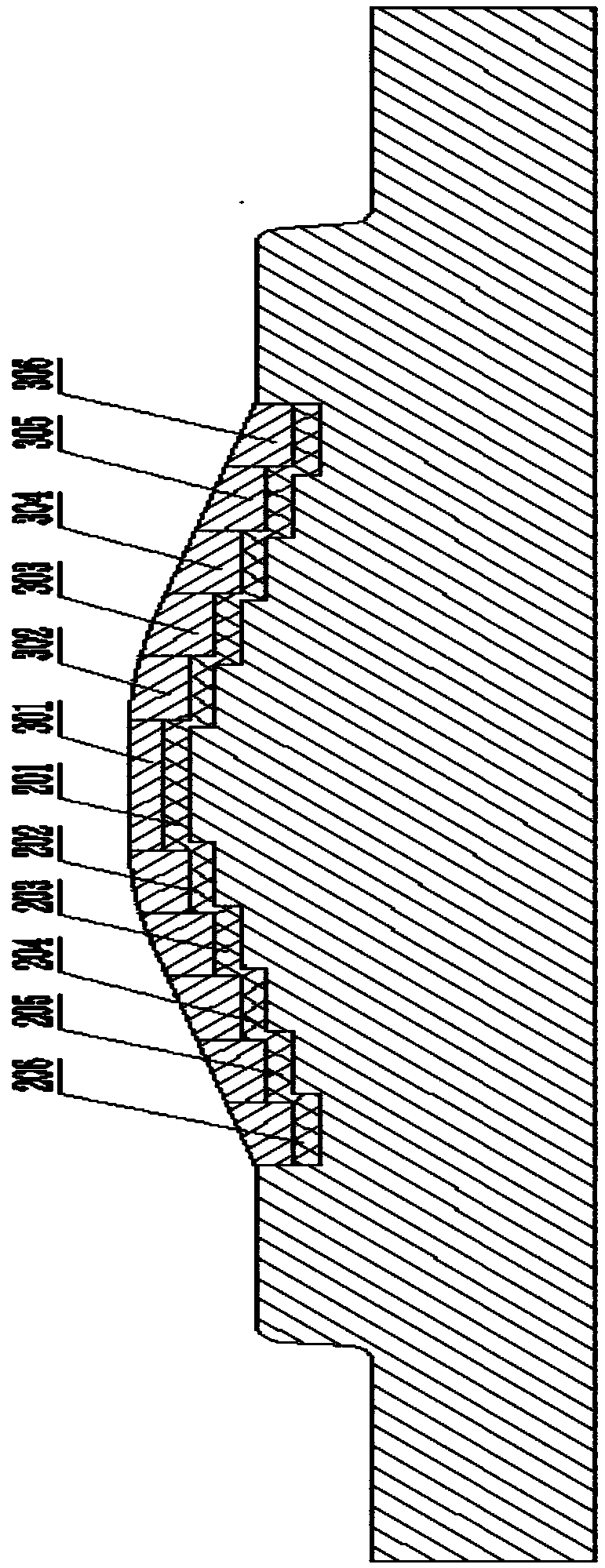

[0048] The shape and depth of the welding layer are milled on the mold base 100, and the welding layer is processed into a stepped structure that gradually decreases from the center of the working surface to the surroundings, which can increase the contact area between the mold base and the welding layer, and is conducive to improving the welding layer. hardness, strength and wear resistance;

[0049] Step 3: Heat treatment before welding

[0050] Pre-weld heat treatment is performed on the mold base 100, followed by stress relief, quenching and tempering processes:

[0051] S1. Perform high-temperature temp...

Embodiment 2

[0070] The difference with embodiment 1 is:

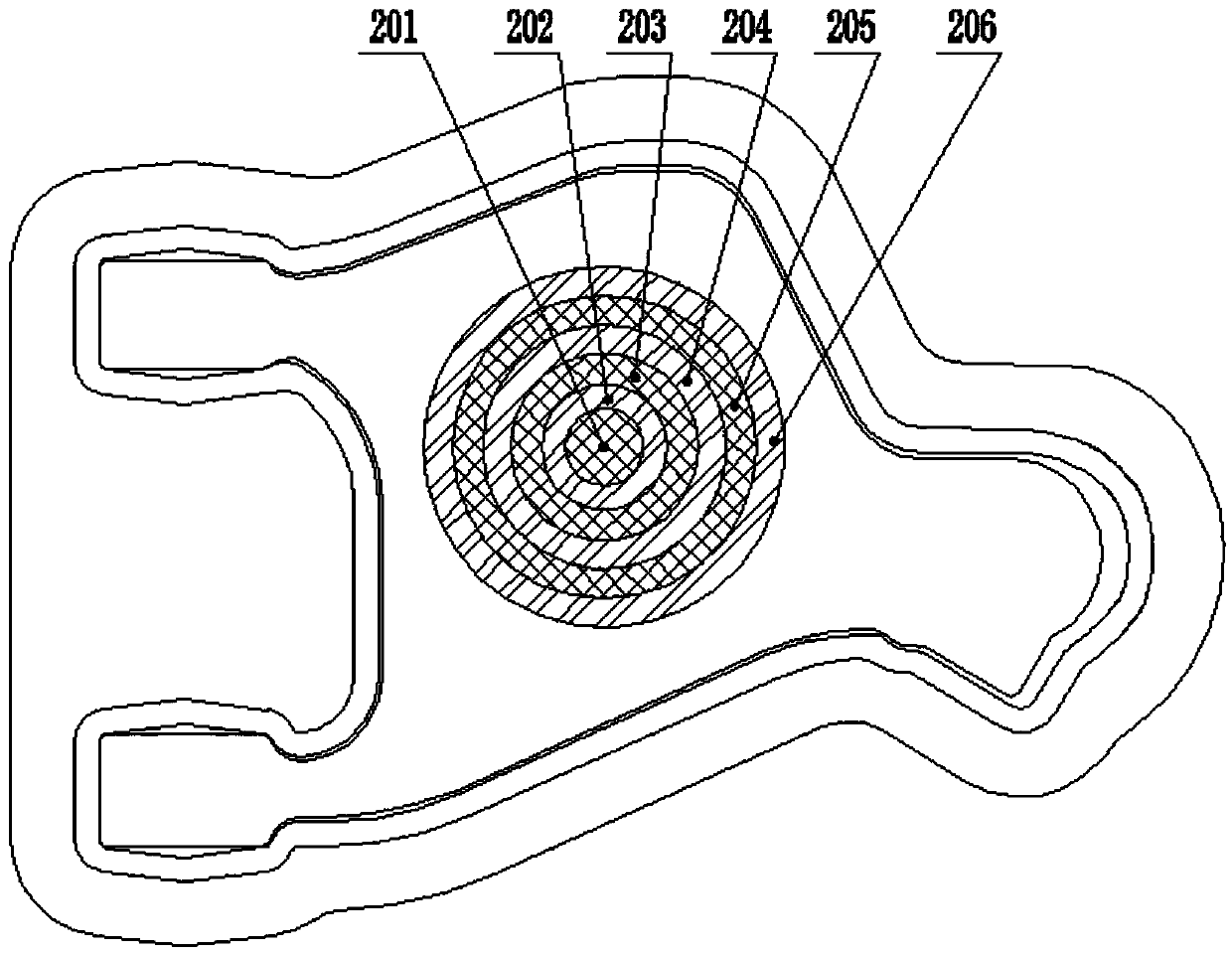

[0071] The sixth surfacing layer 201 , the fifth surfacing layer 202 , the fourth surfacing layer 203 , the third surfacing layer 204 , the second surfacing layer 205 and the first surfacing layer 206 are all vertically connected to the mold base 100 .

[0072] The thickness of the welding layers from the sixth welding overlay layer 201 to the first welding overlay layer 206 increases step by step.

[0073] The thicknesses of the welding layers from the seventh welding overlay layer 301 to the twelfth welding overlay layer 302 increase step by step.

[0074] The gradual increase in the thickness of the welding layer is beneficial to the stress of the twelfth surfacing layer 306 to the seventh surfacing layer 301 when working on the working face in the later stage, so as to prevent excessive stress deformation from affecting the use of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com