Compounding and forming integrated device and method for multi-layer metal micro-channel structure

A micro-channel structure and micro-channel technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of micro-channel research with strict operation requirements, not suitable for the field of metal materials, complex structure of preparation devices, etc. The effect of short process flow, reduction of material deformation resistance and friction coefficient, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. The methods used in the present invention are conventional methods unless otherwise specified; the raw materials and devices used are conventional commercially available products unless otherwise specified.

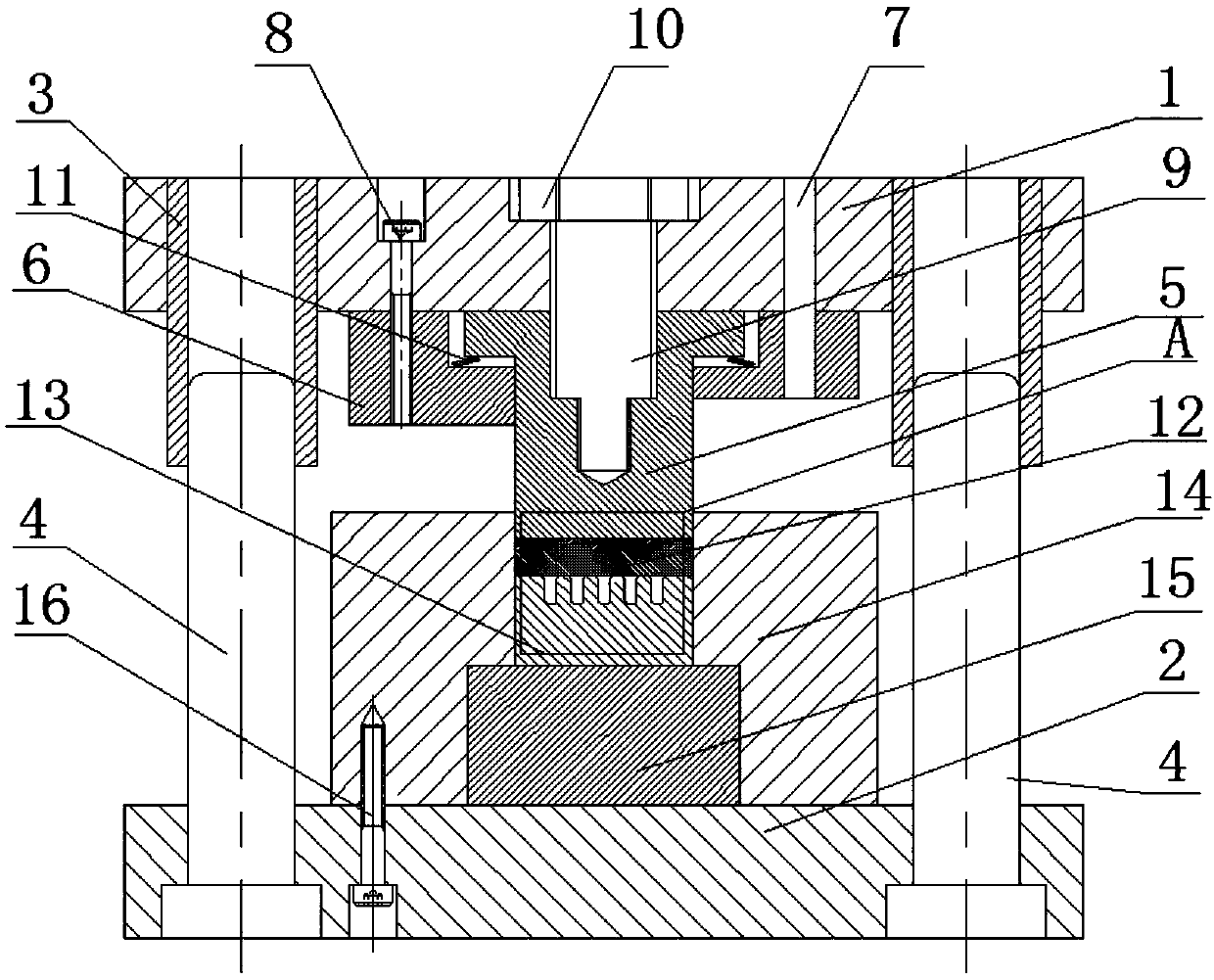

[0026] like Figure 1-Figure 2 As shown, the present invention provides an integrated device for compounding and forming of a multilayer metal microchannel structure, including a matching upper mold base 1 and a lower mold base 2, and the upper mold base 1 and the lower mold base 2 pass through the guide sleeve 3 and the guide post 4 are connected to form a closed frame structure. The upper mold base 1 can realize up and down reciprocating movement through the guide sleeve 3 and the guide column 4; the guidance between the upper template 1 and the lower template 2 is guaranteed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com