Filter membrane for removing low density lipoproteins, and preparation method thereof

A low-density lipoprotein and filter membrane technology is applied in the field of low-density lipoprotein-removing filter membrane and its preparation, which can solve the problems of inability to regenerate, ligand shedding, and only one-time use, and improve biocompatibility. Sexuality, LDL-lowering, and stability-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

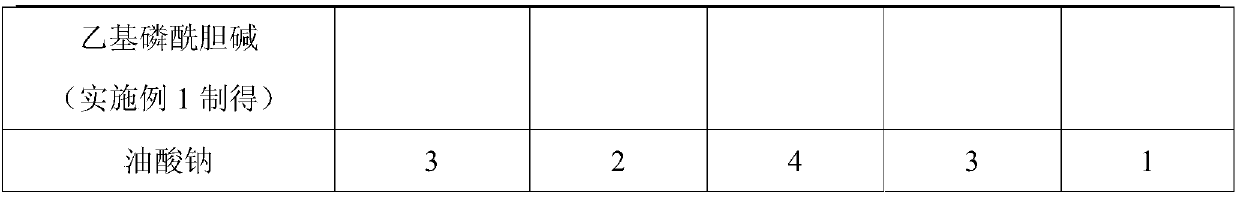

Examples

Embodiment 1

[0027] The preparation of embodiment 1 poly 2-methacryloyloxyethyl phosphorylcholine

[0028] Weigh 4.651g (15.77mmol) of MPC monomer, dissolve it in 15mL of methanol to make a solution with a concentration of 0.31g / mL, add 0.046g (0.28mmol) of azobisisobutyronitrile as an initiator, and under the protection of nitrogen, Stir and heat to 60°C, and react for 10 hours. After the reaction, cool down, add diethyl ether to precipitate, collect the lower precipitate, and dry it in vacuum to obtain poly-2-methacryloyloxyethyl phosphorylcholine.

Embodiment 2

[0029] The preparation of embodiment 2 amphiphilic chitosan

[0030] (1) Dissolve chitosan in acetic acid to make a chitosan-acetic acid solution with a concentration of 2% (m / v), and dissolve deoxycholic acid in ethanol to make a concentration of 2% (m / v). Deoxycholic acid ethanol solution; the chitosan acetic acid solution is mixed with deoxycholic acid ethanol solution, stirred evenly, and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride ( EDC), reacted at 25°C for 24h, after the product was neutralized by ammonia water, precipitated with methanol, filtered, dialyzed the filtrate with deionized water, and freeze-dried to obtain an intermediate product; wherein, chitosan, deoxycholic acid The mass ratio to EDC is 8:1:0.2.

[0031] (2) The intermediate product obtained in step (1) is added with a concentration of 40% (m / v) sodium hydroxide solution in a ratio of 1:4 by solid-to-liquid ratio, mixed evenly, and added with sodium hydroxide solution under agitation C...

Embodiment 3

[0032] The preparation of embodiment 3 sulfonic acid group modified cellulose acetate

[0033] Weigh 20g of vinylsulfonic acid and 100g of cellulose acetate, mix them, add chloroform 10 times the weight of cellulose acetate, stir to dissolve, add 0.4g of ammonium persulfate, mix well, under nitrogen protection, at 100℃ The reaction was carried out for 24 hours, and after the reaction was completed, it was repeatedly washed with water and ethanol for 4 times, and dried in vacuum to obtain sulfonic acid group-modified cellulose acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com