Preparation method of manganous oxide negative electrode material of magnesium ion battery

A manganese oxide negative electrode and magnesium ion battery technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor matching of positive electrode materials, large interface impedance of electrode materials, and low ion conductivity, so as to improve the charge-discharge ratio The capacity, the method is simple and easy, and the effect of high theoretical specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Dissolve 17.246g of soluble analytically pure manganese sulfate monohydrate in 200mL deionized water, slowly add 90mL of oxalic acid aqueous solution with a mass percentage concentration of 15% under magnetic stirring to obtain manganese oxalate precipitation, continue stirring for 30 minutes, filter, and use Wash with ionic water until no sulfate is detected, and dry at 60°C to obtain a manganous oxalate precursor.

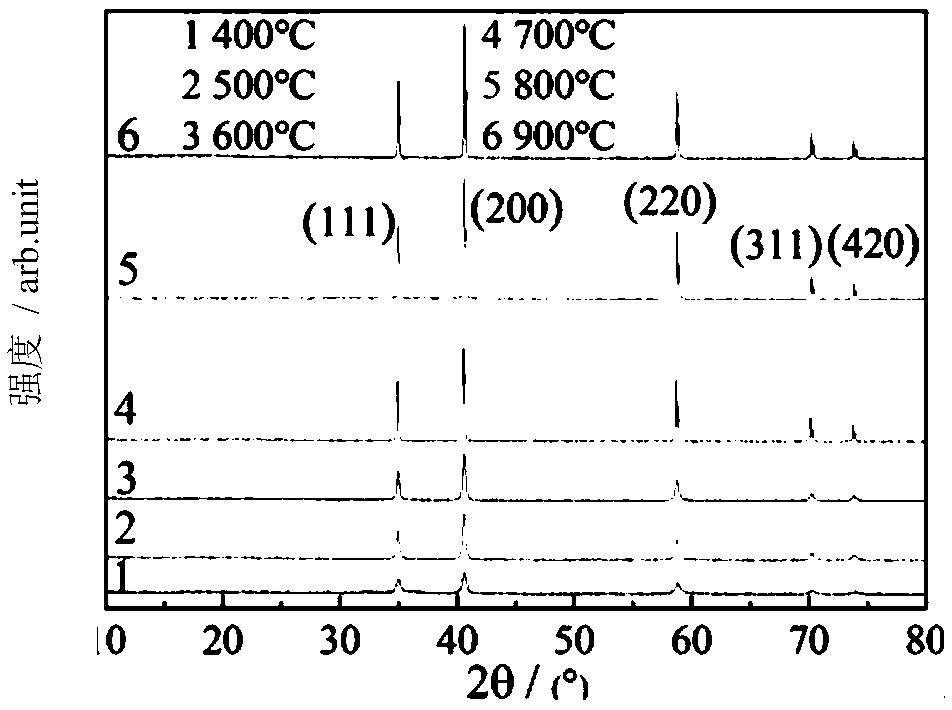

[0019] (2) Raise the temperature of the manganous oxalate precursor obtained in step (1) to 400 °C at a rate of 5 °C / min in an argon-flowing tube furnace, keep it warm for 1 hour, cool down to room temperature naturally, take it out and grind it to obtain a manganous oxide negative electrode Material. For the XRD spectrum of manganese oxide prepared at 400°C, see figure 1 , the search results show that the prepared manganous oxide has a face-centered cubic structure (corresponding to JCPDS No.07-0230), without other impurity phases. For the SEM photo...

Embodiment 2

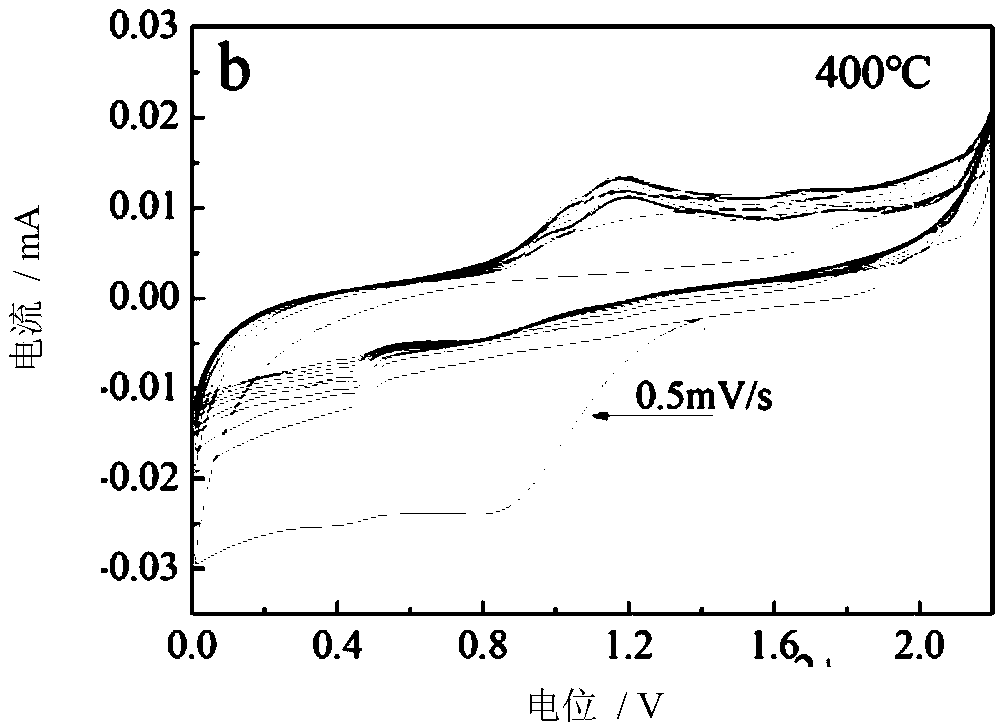

[0023] Using the manganous oxalate prepared in step (1) of Example 1 as raw material, prepare manganous oxide negative electrode materials at 500°C, 600°C and 700°C, 800°C, and 900°C roasting temperatures respectively, according to step (2) of Example 1 Assemble the battery, see the charging and discharging performance test results Figure 4 , Figure 5 . The results showed that the initial charge-discharge capacity and cycle capacity of the manganese oxide negative electrode material decreased slowly with the increase of the calcination temperature of manganese oxalate, which may be related to the gradual growth of the grains of the manganese oxide with the increase of the calcination temperature. The poor electrical conductivity of manganous oxide is unfavorable to its electrochemical performance. Therefore, nanonization of particle size and improvement of electrical conductivity are necessary prerequisites for improving the performance of manganous oxide negative electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com