Photo-crosslinking stabilized hyperbranched free radical polymer and preparation method and application thereof

A free radical and stabilization technology, applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problems of machinability, non-rechargeable battery life, etc., achieve good mechanical properties, avoid battery life decline, molecular weight and the effect of increasing the glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation method

[0046] A photocrosslinkable stabilized hyperbranched free radical polymer prepared by the following method:

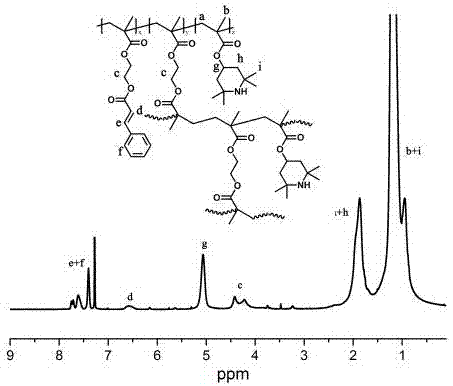

[0047] (1) Add 1.624g of 2,2,6,6-tetramethyl-4-piperidinyl methacrylate and 0.208g of methacryloyloxyethyl cinnamate in sequence to a 20mL dry ammeter tube , 0.16g of ethylene glycol dimethacrylate, 44.4mg of 4-cyano-4-(propyl trithiocarbonate)-pentanoic acid and 5.2mg of azobisisobutyronitrile (ie its mole ratio of 90:10:10:2:0.4), and 8 mL of tetrahydrofuran as a solvent, nitrogen was passed through to remove oxygen, and the tube was sealed in vacuum. After the reaction was continued for 18 h under heating at 60° C., the reaction solvent was removed by rotary evaporation to obtain the hyperbranched polymer hb-poly(TMPM-co-CEMA).

[0048] (2) Get 1g of gained hyperbranched polymer and 0.854g m-chloroperoxybenzoic acid (i.e. the mol ratio of piperidinyl unit and m-chloroperoxybenzoic acid is 1:1.1), be dissolved in 250mL dichloromethane...

Embodiment 2

[0054] 1. Preparation method

[0055] According to the same preparation method as in Example 1, but the feeding was changed to 1.624g of 2,2,6,6-tetramethyl-4-piperidinyl methacrylate, 0.208g of methacryloxyethyl cinnamon ester, 40 mg of ethylene glycol dimethacrylate, 44.4 mg of 4-cyano-4-(propyltrithiocarbonate)-pentanoic acid and 5.2 mg of azobisisobutyronitrile, which The molar ratio is 90:10:2.5:2:0.4. After post-treatment under the same conditions as in Example 1, a hyperbranched radical polymer (hb-2) capable of photocrosslinking and stabilization was obtained.

[0056] 2. Product characteristics and physical and chemical properties

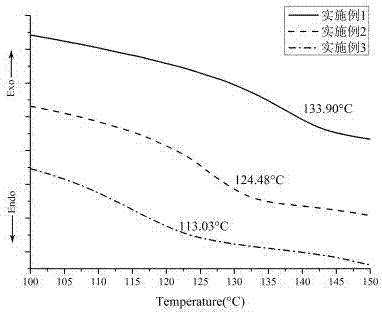

[0057] (1) if figure 2 As shown, the glass transition temperature of the obtained photocrosslinkable and stabilized hyperbranched radical polymer (hb-2) is 124.48°C.

[0058] (2) Using the same method as in Example 1 to prepare an electrode, the measured electrode capacity is 83mAh, and the coulombic efficiency is nearly 100% and the ...

Embodiment 3

[0060] 1. Preparation method

[0061] According to the same preparation method as in Example 1, but the feeding was changed to 1.624g of 2,2,6,6-tetramethyl-4-piperidinyl methacrylate, 0.208g of methacryloxyethyl cinnamon ester, 16 mg of ethylene glycol dimethacrylate, 44.4 mg of 4-cyano-4-(propyltrithiocarbonate)-pentanoic acid and 5.2 mg of azobisisobutyronitrile, which The molar ratio is 90:10:1:2:0.4. After post-treatment under the same conditions as in Example 1, a hyperbranched radical polymer (hb-3) capable of photocrosslinking stabilization was obtained.

[0062] 2. Product characteristics and physical and chemical properties

[0063] (1) if figure 2 As shown, the glass transition temperature of the obtained photocrosslinkable and stabilized hyperbranched radical polymer (hb-3) is 113.03°C.

[0064] (2) Using the same method as in Example 1 to prepare an electrode, the measured electrode capacity is 86mAh, and the coulombic efficiency is nearly 100% and the capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com