Method for constructing controllable crystallinity bacterial cellulose genetic engineering producing strains and product and application thereof

A technology of bacterial cellulose and a construction method is applied in the field of construction of bacterial cellulose genetic engineering production bacteria with controllable crystallinity, and can solve the problems of insufficient modification of cellulose, clogging of matrix grids, and difficulty in obtaining sufficient modification. , to achieve the effect of weakening mechanical properties, improving water retention, and reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

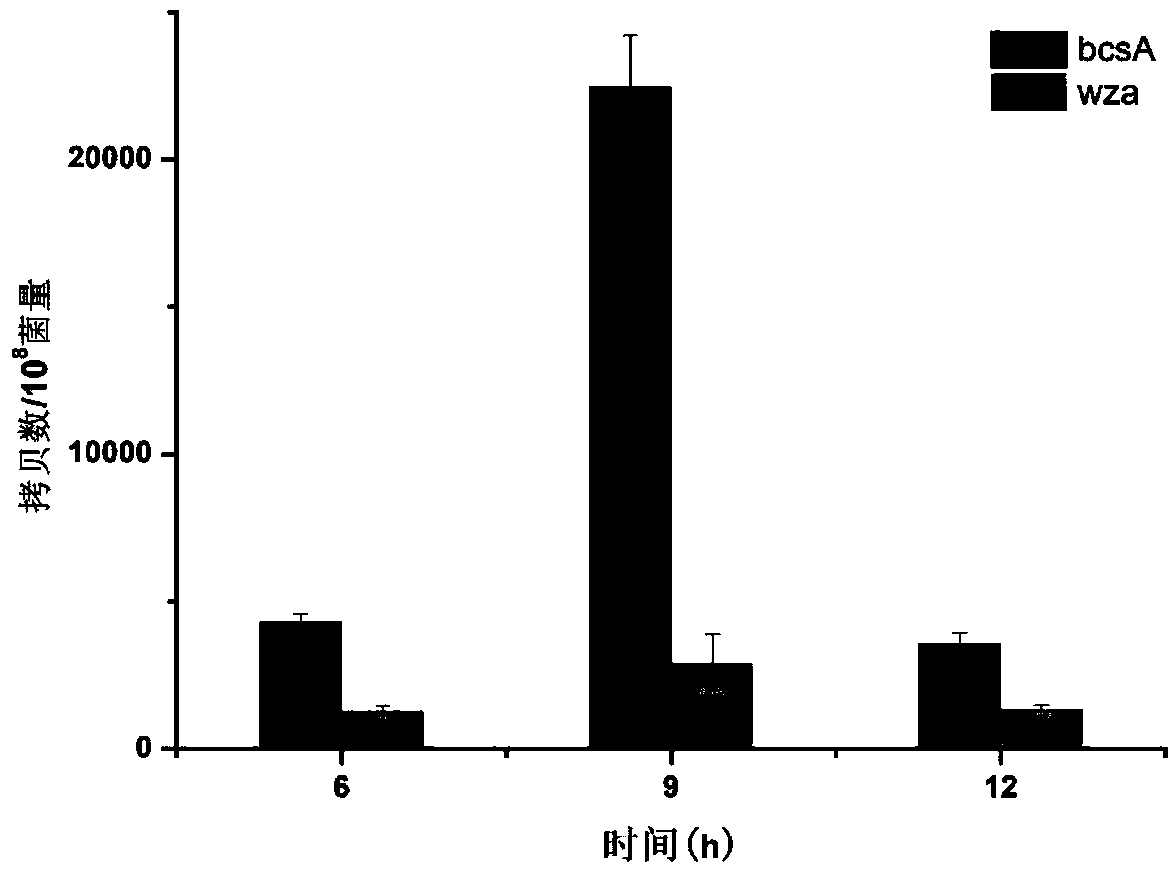

[0064] Purification and characterization of water-soluble polysaccharides from Enterobacter sp.FY-07ΔbcsIII

[0065] Enterobacter sp.FY-07ΔbcsIII strain was aerobically cultured in Li-Zhao medium at 30°C and 200rpm for 48h, and the fermentation broth was heated in boiling water for 30min to promote the separation of bacterial sugars. After the mixture was diluted 5 times, it was centrifuged at 12000×g for 30 minutes at a high speed, and the supernatant after centrifugation was heated again in boiling water, and the remaining bacteria were filtered out with a 0.20 μm filter membrane. Add 4 volumes of absolute industrial ethanol to the filtrate, and precipitate the polysaccharide overnight at 4°C. The precipitated polysaccharides were collected and vacuum freeze-dried. The dried polysaccharides were redissolved in distilled water, dialyzed at 4°C for 3 days, and then freeze-dried again to obtain pure polysaccharides.

[0066] High performance liquid chromatography (HPLC) was us...

Embodiment 2

[0068] Verification of colatin synthesis gene

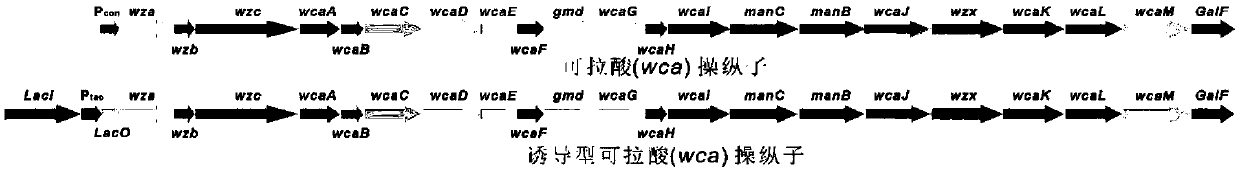

[0069] The whole genome of Enterobacter sp.FY-07 was analyzed using tools such as gene annotation, tRNA / rRNA prediction, COG / KEGG / GO analysis, and comparative genome analysis. Through comparative genome analysis, it was found that there is a complete gene cluster of colanic acid synthesis (wca operon) on the genome of Enterobacter sp.FY-07, and the related gene map is as follows: figure 1 shown). The gene cluster was verified by knocking out and inactivating two key enzymes in the kolanic acid synthesis pathway, wcaJ and wcaK.

[0070] In order to construct a gene knockout vector, primers caJ-SF / caJ-SR, caJ-XF / caJ-XR and caK-SF / caK-SR, caK-XF / caK-XR were amplified from Enterobacter sp.FY-07 genome Increase the 1.5kb upstream and downstream homology arms of the target gene. The obtained fragments were overlapped PCR with primers caJ-SF, caJ-XR and caK-SF, caK-XR, and the overlapping fragments were treated with restriction endon...

Embodiment 3

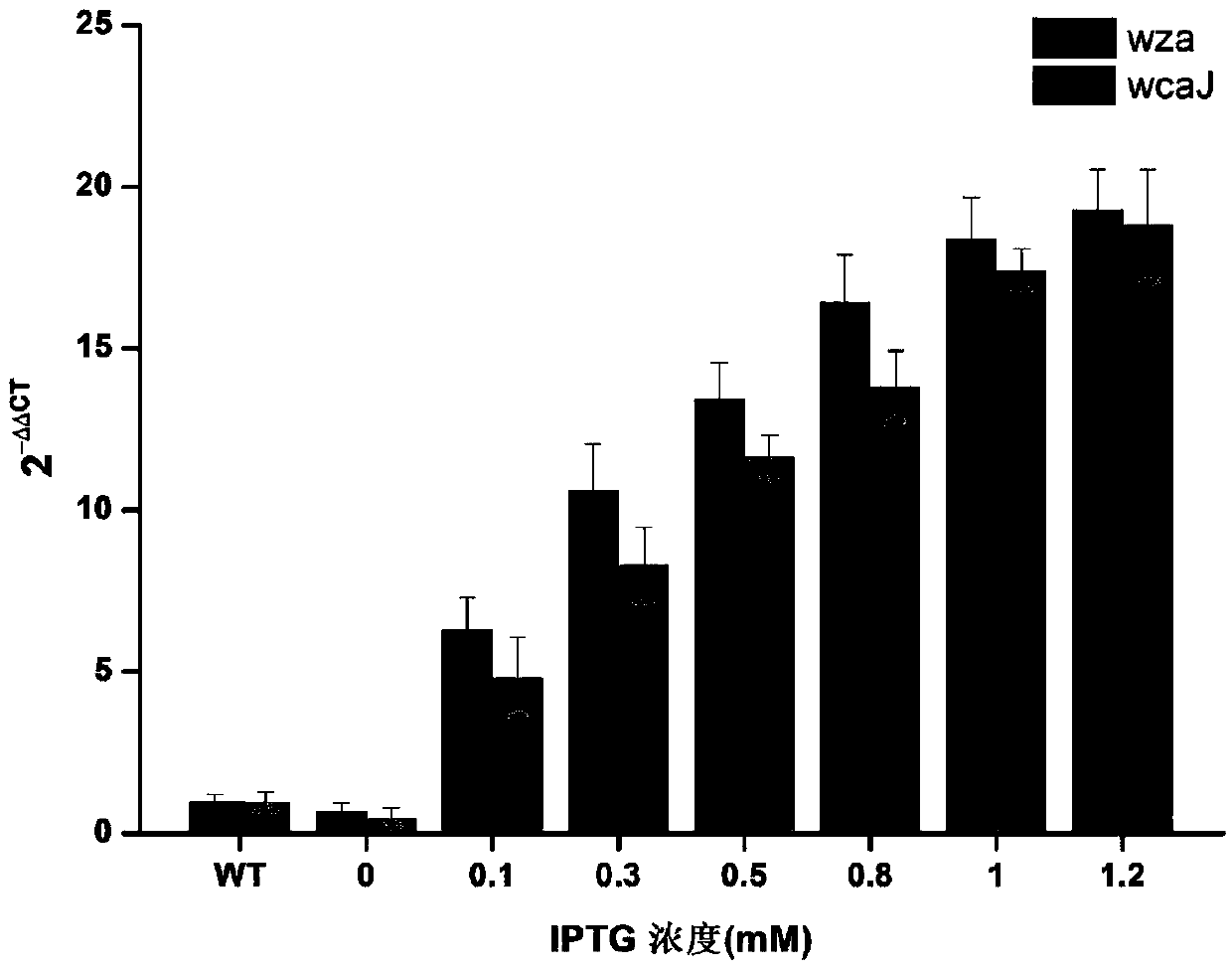

[0072] Construction and validation of an inducible wca operon

[0073] Using primers 1U / 1L and 2U / 2L, a 1.5kb gene sequence was amplified from the genome of Enterobacter sp.FY-07, upstream and downstream of the promoter encoding CA synthetase of wca operon. The tac promoter fragment was amplified from pMMB66eh with primers tacU / tacL. The fragment obtained by overlapping PCR fusion with primers 3U / 3L was digested with XbaI and XhoI and ligated into pTSK1. The pTSK1-tac plasmid was introduced into Enterobacter sp.FY-07, and the transformant grown on the medium with carbenzyl and tetracycline resistance was successfully verified by PCR with primers 1U and 2L, and was cultured in LB medium for 37 °C overnight cultures are used for single crossover and plasmid loss to occur. 10 μL of bacterial solution was diluted and spread on LB plates with tetracycline, and then incubated at 42°C for 12 hours. The single-exchange colonies successfully identified by PCR with primers K1U / K1L an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com