Super hard yellowing resistant epoxy floor coating

A technology of changing epoxy floor and yellowing resistance, applied in the field of floor materials, it can solve the problems of poor aging resistance and yellowing resistance, easy yellowing, and unclean surface, and achieve strong aging resistance and good wear resistance. , the effect of reducing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

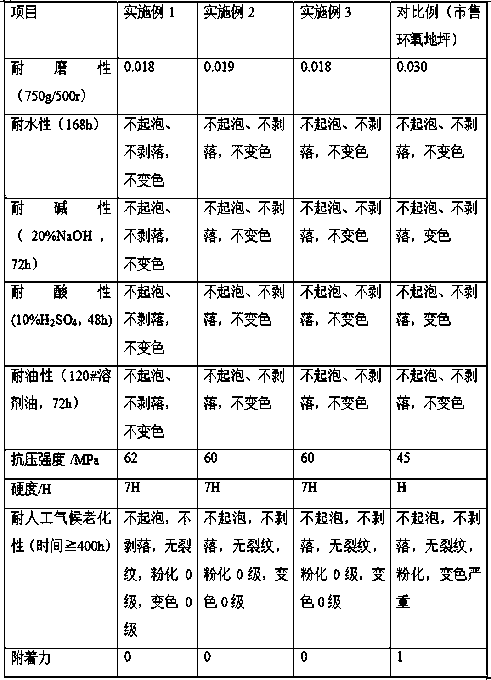

Examples

Embodiment 1

[0018] The superhard anti-yellowing epoxy floor paint, the paint is composed of A component and B component, and the A component includes the following raw materials: by weight, 45 parts of bisphenol A epoxy resin, glycerin epoxy resin 8 parts of resin, 8 parts of phenyl glycidyl ether, 1 part of cyclohexanol, 20 parts of precipitated barium sulfate, 40 parts of quartz powder, 10 parts of color paste, 0.5 parts of silicon carbide powder, 0.6 parts of AKN-2048, 0.05 parts of AKN-33570 , AKN-157B 0.8 parts, anti-yellowing agent 0.8 parts;

[0019] Component B includes the following raw materials: by weight, 40 parts of methyltetrahydrophthalic anhydride and 1 part of dihydroxydiethylenetriamine.

[0020] The mass ratio of the A component to the B component is 3:1.

[0021] The preparation method is: mix and stir components A and B for 0.5~1h,

Embodiment 2

[0023] The superhard anti-yellowing epoxy floor paint, the paint is composed of A component and B component, A component includes the following raw materials: by weight, 48 parts of bisphenol A epoxy resin, glycerin epoxy resin 9 parts of resin, 9 parts of phenyl glycidyl ether, 3 parts of cyclohexanol, 25 parts of precipitated barium sulfate, 45 parts of quartz powder, 11 parts of color paste, 0.7 parts of silicon carbide powder, 0.8 parts of AKN-2048, 0.1 parts of AKN-33570 , 0.9 parts of AKN-157B, 0.9 parts of anti-yellowing agent, 5 parts of modified polyimide fiber, 0.3 parts of BYK360, 2 parts of isopropanol.

[0024] The preparation method of the modified polyimide fiber is as follows: 4,4'-diaminodiphenyl ether and pyrophthalic anhydride are reacted in a polar solvent with a molar ratio of 1:1 to generate polyamic acid. Polyamic acid continuous fiber is obtained by wet method or dry spray wet spinning method; then polyvinylpyrrolidone and cyclodextrin are added to the ...

Embodiment 3

[0029] The superhard anti-yellowing epoxy floor paint, the paint is composed of A component and B component, A component includes the following raw materials: by weight, 50 parts of bisphenol A type epoxy resin, glycerin epoxy resin 10 parts of resin, 10 parts of phenyl glycidyl ether, 5 parts of cyclohexanol, 30 parts of precipitated barium sulfate, 50 parts of quartz powder, 12 parts of color paste, 1 part of silicon carbide powder, 0.9 parts of AKN-2048, 0.2 parts of AKN-3357 1.0 parts of AKN-157B, 1.3 parts of anti-yellowing agent, 8 parts of modified polyimide fiber, 0.3 parts of BYK360, 2 parts of isopropanol.

[0030] The preparation method of the modified polyimide fiber is as follows: 4,4'-diaminodiphenyl ether and pyrophthalic anhydride are reacted in a polar solvent at a molar ratio of 1:1 to generate polyamic acid. Polyamic acid continuous fiber is obtained by wet method or dry spray wet spinning method; then polyvinylpyrrolidone and cyclodextrin are added to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com