Grease-resistant high-impact polyphenylene oxide (PPO) composite material and preparation method thereof

A composite material and high-impact technology, which is applied in the field of grease-resistant and high-impact PPO composite materials and its preparation, can solve the problems of not achieving high impact resistance, not researching oil-resistant stress cracking, etc., to ensure physical properties and stable production properties, improved oil and grease resistance, and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

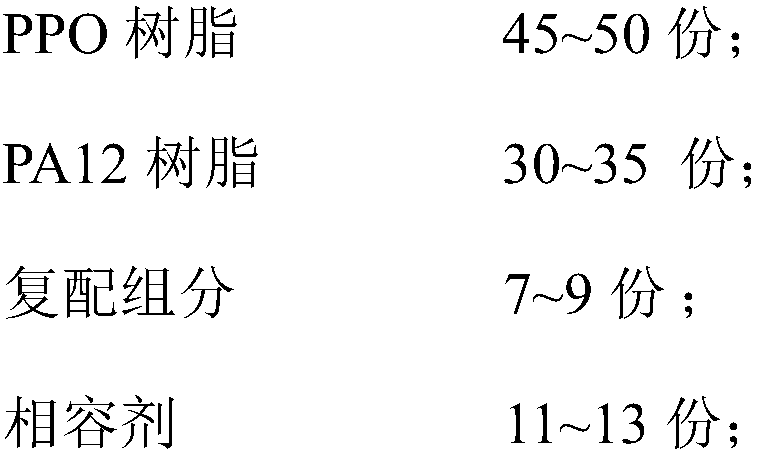

Method used

Image

Examples

Embodiment 1

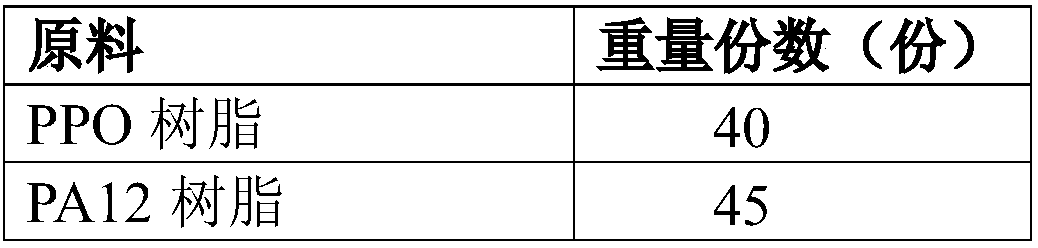

[0035] According to the raw materials in parts by weight shown in Table 1, the PPO composite material was prepared.

[0036] The formula composition of table 1 embodiment 1

[0037]

[0038]

[0039] Among them, the copper element concentration in the PPO resin is 12ppm, and the intrinsic viscosity is 52cm 3 / g.

[0040] The melt index of PA12 resin at 230°C / 2.16Kg is 12g / 10min.

[0041] The preparation method of the present embodiment PPO composite material comprises the following steps:

[0042] 1) Mix AS resin, maleic anhydride and SEBS evenly, feed them into the single-screw extruder from the main feed, then feed calcium sulfate whiskers and PTFE into the extruder from two side feed systems respectively , melt blending extrusion granulation to obtain masterbatch;

[0043] 2) PPO resin is fed into the twin-screw extruder from the main feeding port, and PA12 resin and the above-mentioned masterbatch are fed into the extruder from two side feeding systems respective...

Embodiment 2

[0045] According to the raw materials in parts by weight shown in Table 2, the PPO composite material was prepared.

[0046] The formula composition of table 2 embodiment 2

[0047] raw material

Parts by weight (parts)

PPO resin

50

PA12 resin

30

AS resin

2

PTFE

4

2

Compatibilizer

12

[0048] Among them, the concentration of copper element in PPO resin is 8ppm, and the intrinsic viscosity is 52cm 3 / g.

[0049] PA12 resin is identical with embodiment 1.

[0050] The preparation method of the PPO composite material in this example is the same as that in Example 1.

Embodiment 3

[0052] According to the raw materials in parts by weight shown in Table 3, the PPO composite material was prepared.

[0053] The formula composition of table 3 embodiment 3

[0054] raw material

Parts by weight (parts)

PPO resin

45

PA12 resin

35

AS resin

2

PTFE

4

calcium sulfate whiskers

2

Compatibilizer

12

[0055] Wherein, PPO resin and PA12 resin are identical with embodiment 2.

[0056] The preparation method of the PPO composite material in this example is the same as that in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com