Grinding method and device for fermented Chinese cordyceps sinensis fungus powder

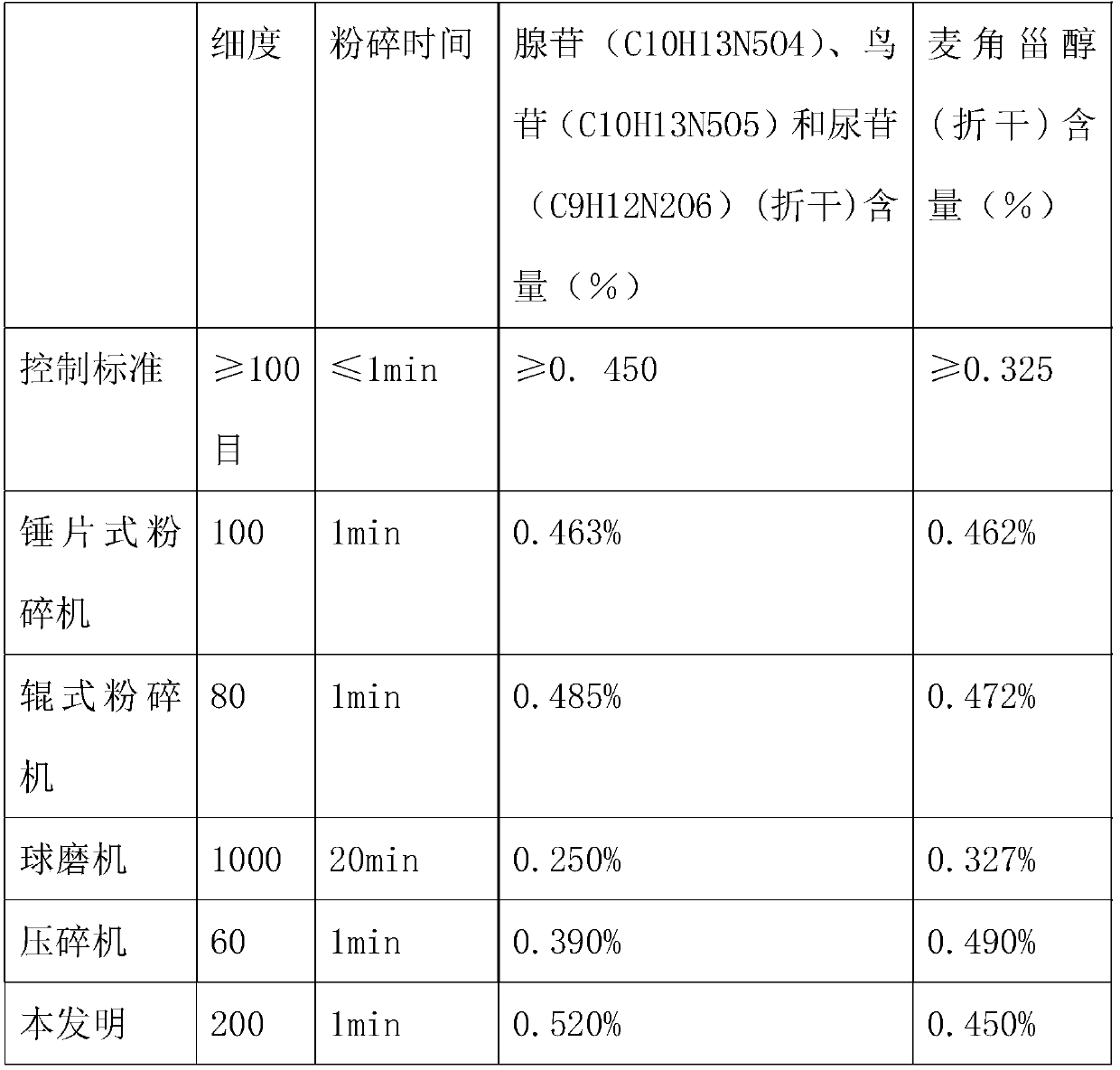

A technology of fermenting Cordyceps fungus powder and crushing device, which is applied in the direction of making drugs into special physical or ingestible devices, grain processing, etc., which can solve the problem of uneven particle shape and structure, easy sedimentation, slow dissolution rate, etc. problems, to achieve the effect of increasing the dissolution rate and dissolution rate, increasing the wall breaking rate, and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

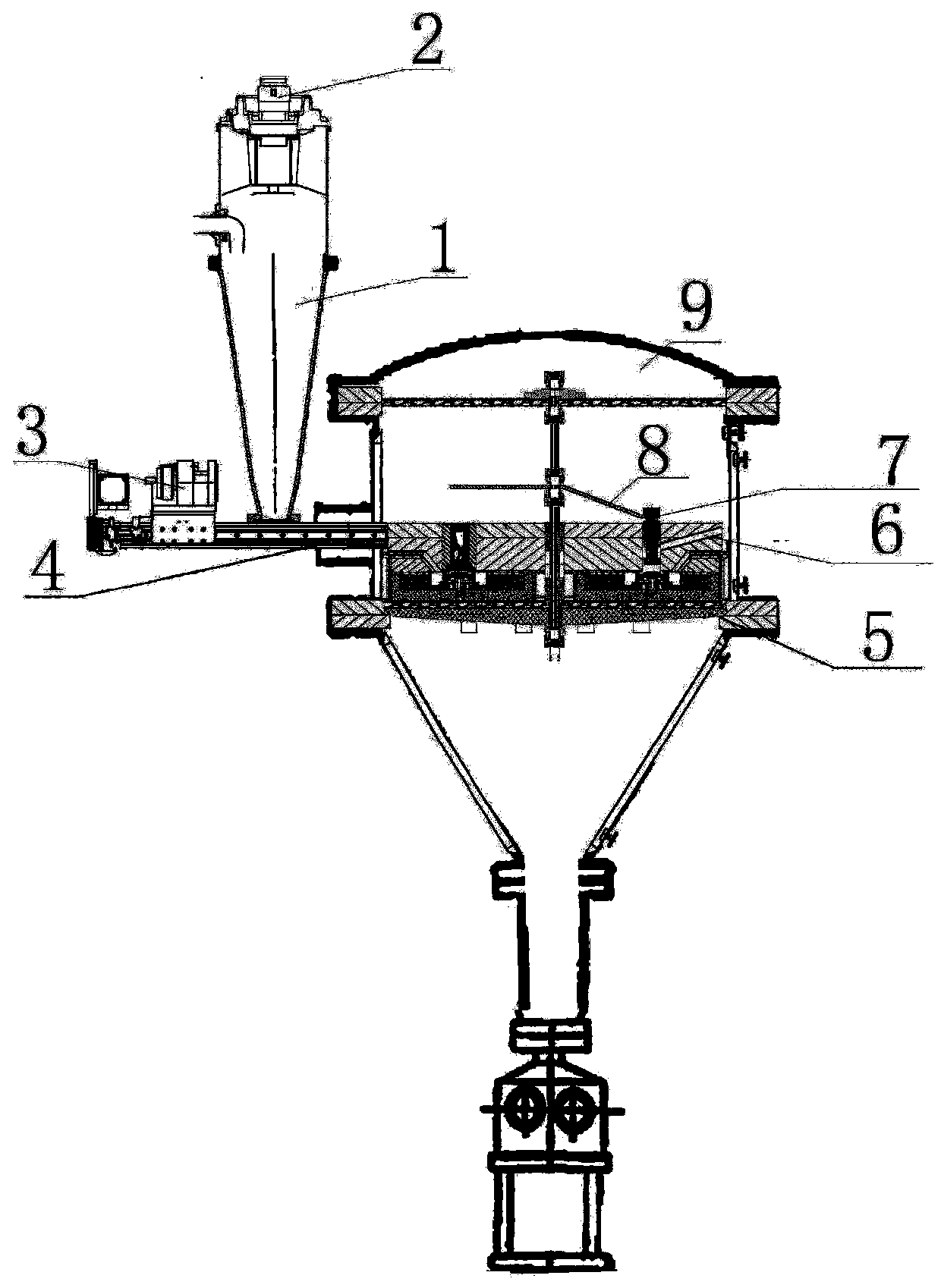

Method used

Image

Examples

Embodiment 1

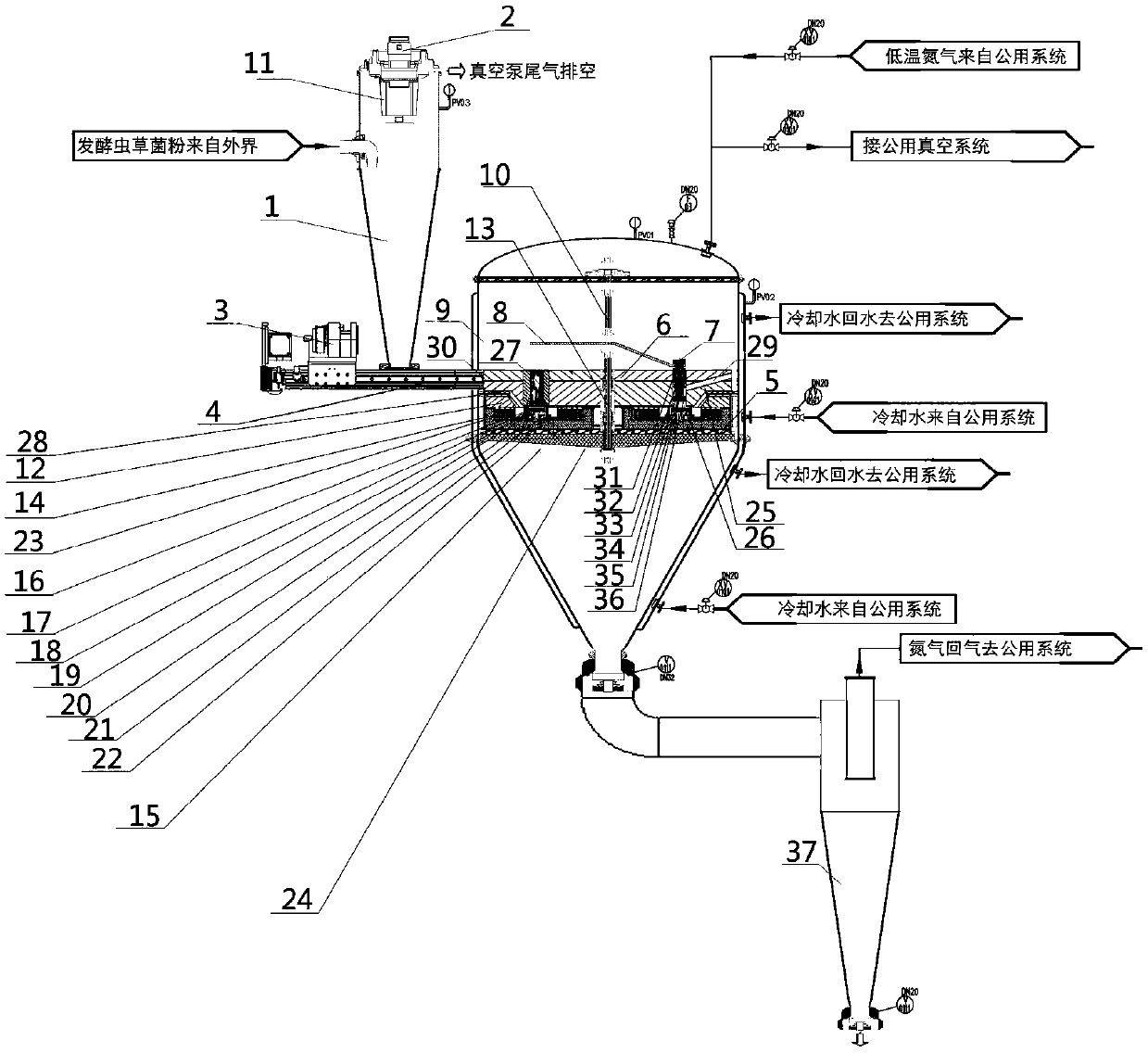

[0057] 1) Install the ultra-fine powder equipment with 5 holes evenly arranged on the circular boss, turn on the vacuum pump, and put 20Kg of fermented Cordyceps powder with a water content of 2.0% and preliminarily crushed through a 60-mesh sieve through a vacuum suction with a sieve Tube suction raw material storage room.

[0058] 2) Set the automatic feeding mechanism to feed 6 times per minute, the feeding amount is 15g / time, the temperature of the frozen brine circulation outlet is 30°C, turn on the frozen brine circulation switch on the double-cooled turntable ultrafine powder preparation device, and turn on the double-cooled turntable The vacuum valve on the ultrafine powder preparation device, when the vacuum degree reaches 0.05MPa, close the vacuum valve and open the nitrogen valve. When the pressure in the system reaches normal pressure, start the fan and adjust it to low speed operation (about 200 rpm). When the feeding volume of the fermented Cordyceps powder reach...

Embodiment 2

[0061] 1) Install the ultra-fine powder equipment with 15 holes evenly arranged on the circular boss, turn on the vacuum pump, and put 40Kg of fermented Cordyceps powder with a water content of 2.7% and preliminarily crushed through a 60-mesh sieve through the vacuum suction material with a sieve Tube suction raw material storage room.

[0062] 2) Set the automatic feeding mechanism to feed 15 times per minute, the feeding amount is 13g / time, the temperature of the frozen brine circulation outlet water is 30°C, turn on the frozen brine circulation switch on the double-cooled turntable type ultrafine powder preparation device, and turn on the double-cooled turntable type For the vacuum valve on the ultrafine powder preparation device, when the vacuum degree reaches 0.05MPa, close the vacuum valve and open the nitrogen valve. When the pressure in the system reaches normal pressure, start the fan and adjust it to a low speed (about 200 rpm). When the feeding volume of the ferment...

Embodiment 3

[0065] 1) Install the ultra-fine powder equipment with 30 holes evenly arranged on the circular boss, turn on the vacuum pump, and put 50Kg of fermented Cordyceps powder with a water content of 3.8% and initially crushed through a 60-mesh sieve through the vacuum suction material with a sieve Tube suction raw material storage room.

[0066] 2) Set the automatic feeding mechanism to feed 30 times per minute, the feeding amount is 12g / time, the temperature of the frozen brine circulation outlet water is 30°C, turn on the frozen brine circulation switch on the double-cooled turntable type ultrafine powder preparation device, and turn on the double-cooled turntable type For the vacuum valve on the ultrafine powder preparation device, when the vacuum degree reaches 0.05MPa, close the vacuum valve and open the nitrogen valve. When the pressure in the system reaches normal pressure, start the fan and adjust it to a low speed (about 200 rpm). When the feeding volume of the fermented C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com