Open-width sand washing machine

A sand washing machine and open-width technology, which is applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve the problem of high resource and energy consumption, fabric damage, and sand washing additive consumption and other issues, to achieve the effect of low resource and energy consumption, increase the contact area, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described:

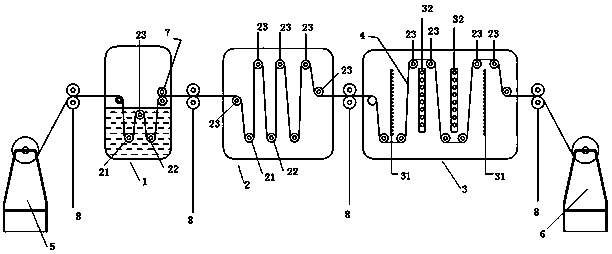

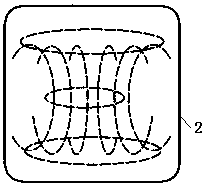

[0038] Such as Figure 1~2 As shown, a kind of open-width sand washing machine includes the input end and the output end of the fabric fabric 4 conveying path, and the fabric fabric 4 conveying path also includes a high-pressure spray box with dry and wet spraying samples for the fabric fabric 4 3. The microwave high-frequency electromagnetic box 2 arranged before the high-pressure spray box 3; the microwave high-frequency electromagnetic box 2 uses the air medium in the microwave box to generate friction so as to further rub the surface of the fabric fabric 4, so that the fabric fabric 4 is opened and made Fiber fluffy. The open-width sand washing machine also includes a cloth rack 5 arranged at the input end of the fabric material 4 and a cloth receiving frame 6 arranged behind the output end of the fabric material 4, and also includes a sand washing auxiliary container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com