Halogen-free flame-retardant heat-shrinkage material for nuclear island, halogen-free flame-retardant heat-shrinkage pipe for nuclear island and preparation method of halogen-free flame-retardant heat-shrinkage material

A heat-shrinkable, inorganic flame retardant technology, applied in the field of heat-shrinkable materials in nuclear islands, can solve problems such as unsatisfactory halogen-free flame retardant performance, unsatisfactory heat aging and radiation resistance performance, and achieve the effect of inhibiting damage and good Flame retardant performance, effect of reducing chain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

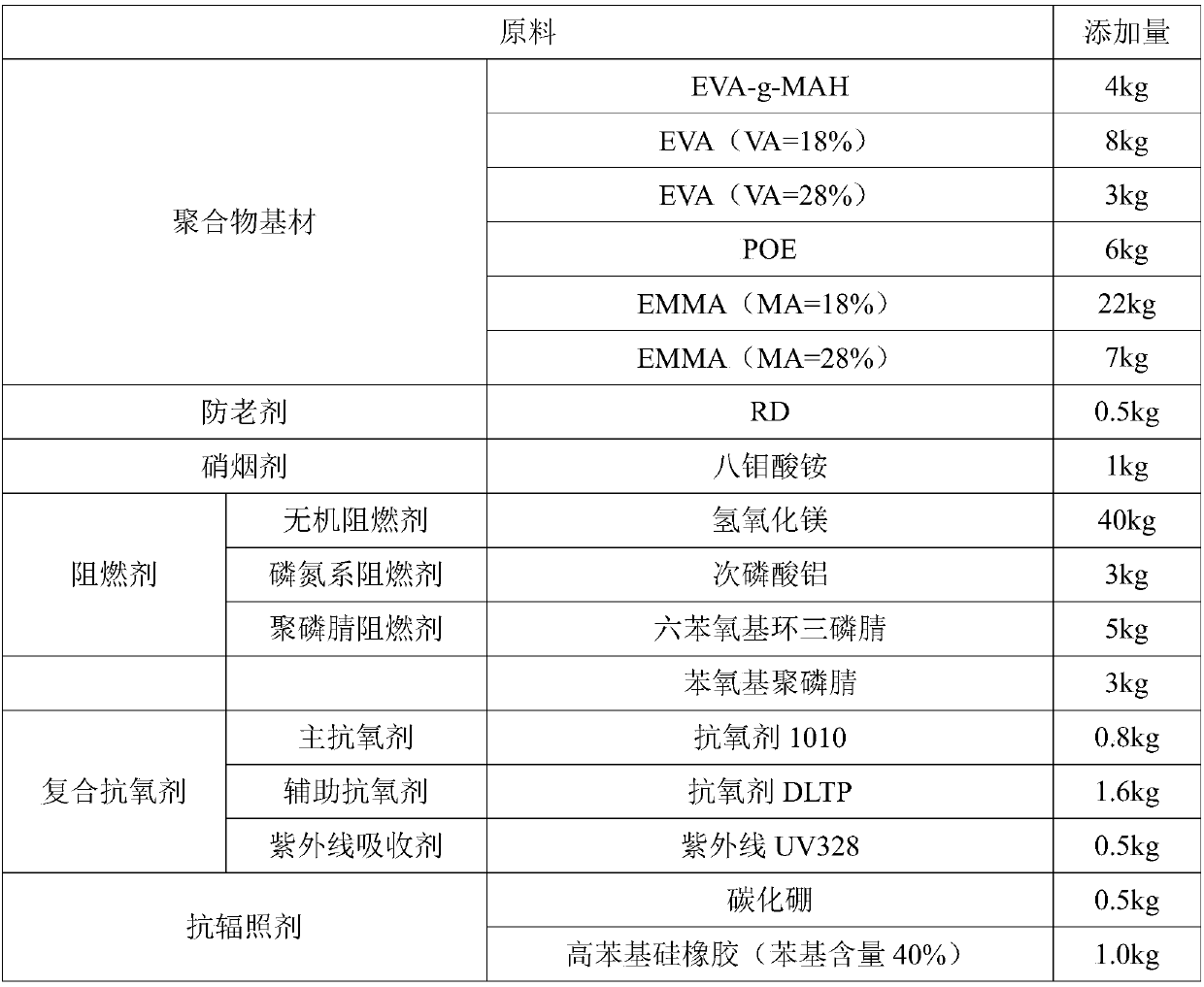

Embodiment 1

[0035]

[0036]

[0037] The polymer EVA-g-MAH, EVA (VA = 18%), EVA (VA = 28%), POE, EMMA (MA = 18%), EMMA (MA = 18%) and antioxidant RD, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, zinc stearate, smoke agent ammonium octamolybdate, boron carbide, magnesium hydroxide, aluminum hypophosphite, hexaphenoxy cyclotriphosphazene, phenoxy polyphosphazene and environmental protection Put the type black masterbatch into a 75-liter internal mixer, mix it at about 130°C for 5 minutes after melting, then add the cross-linking sensitizer TMPTMA, anti-radiation agent A high phenyl silicone rubber (40% phenyl content) And phenylene silicone rubber (60% phenylene content), kneading in the temperature range of 130-150 ° C for 5-10 minutes, and then promoted to the double-stage twin-screw extruder, air cooling in the temperature range of 120-150 ° C Extrude and granulate.

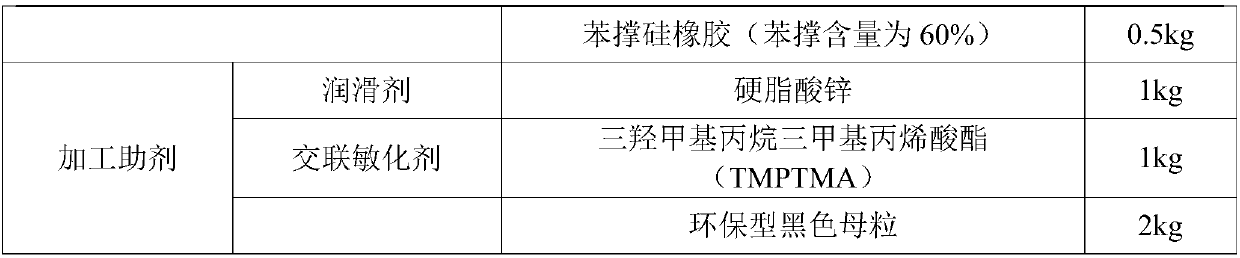

Embodiment 2

[0039]

[0040]

[0041] The polymer EVA-g-MAH, EVA (VA = 18%), EVA (VA = 28%), POE, EMMA (MA = 18%), EMMA (MA = 18%) and antioxidant RD, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, zinc stearate, smoke agent ammonium octamolybdate, boron carbide, magnesium hydroxide, aluminum hypophosphite, hexaphenoxy cyclotriphosphazene, phenoxy polyphosphazene and environmental protection Put the type black masterbatch into a 75-liter internal mixer, mix it at about 130°C for 5 minutes after melting, then add the cross-linking sensitizer TMPTMA, anti-radiation agent A high phenyl silicone rubber (40% phenyl content) And phenylene silicone rubber (60% phenylene content), kneading in the temperature range of 130-150 ° C for 5-10 minutes, and then promoted to the double-stage twin-screw extruder, air cooling in the temperature range of 120-150 ° C Extrude and granulate;

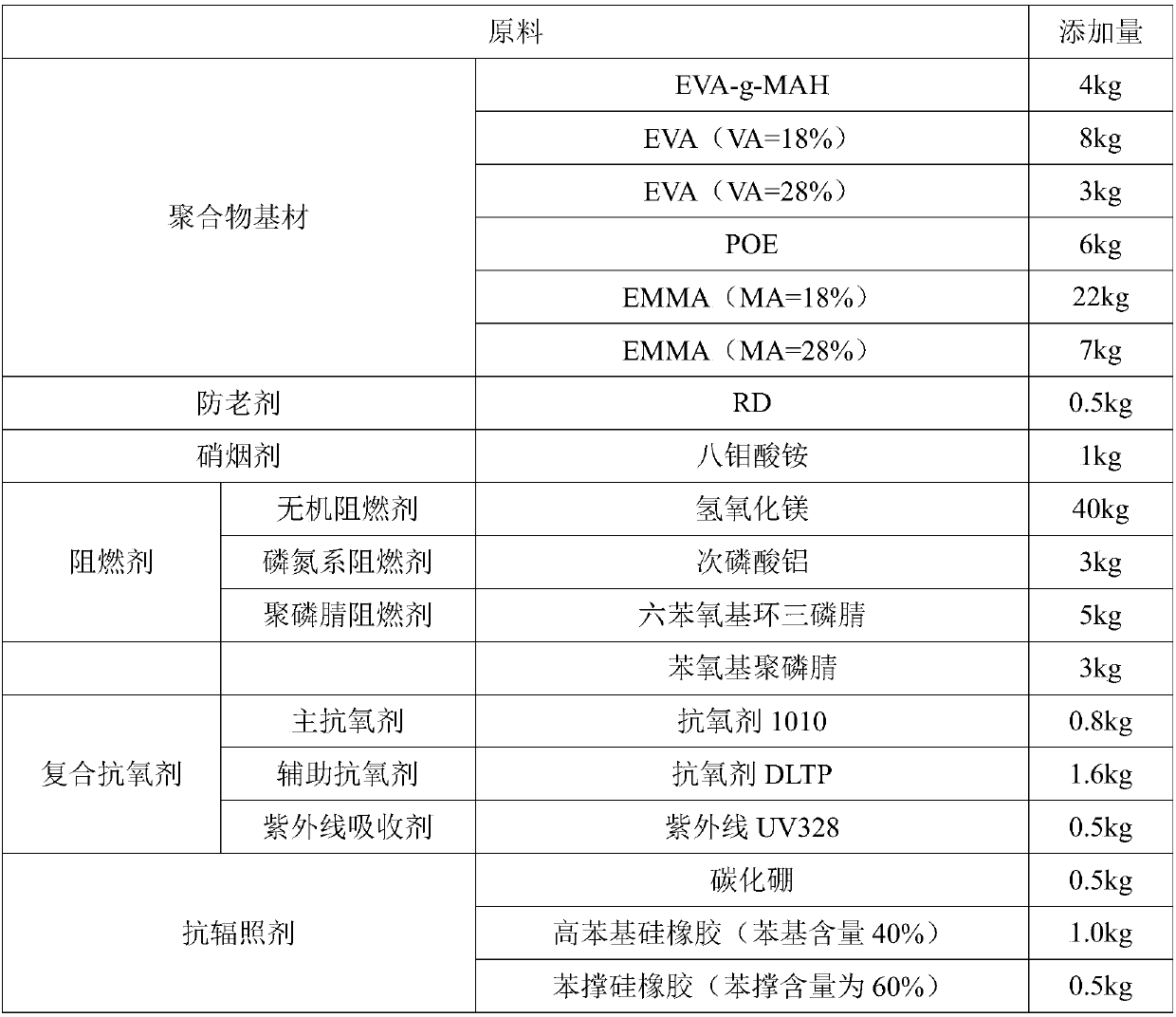

Embodiment 3

[0043]

[0044]

[0045] The polymer EVA-g-MAH, EVA (VA = 18%), EVA (VA = 28%), POE, EMMA (MA = 18%), EMMA (MA = 18%) and antioxidant RD, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, zinc stearate, smoke agent ammonium octamolybdate, boron carbide, magnesium hydroxide, aluminum hypophosphite, hexaphenoxy cyclotriphosphazene, phenoxy polyphosphazene and environmental protection Put the type black masterbatch into a 75-liter internal mixer, mix it at about 130°C for 5 minutes after melting, then add the cross-linking sensitizer TMPTMA, anti-radiation agent A high phenyl silicone rubber (40% phenyl content) And phenylene silicone rubber (60% phenylene content), kneading in the temperature range of 130-150 ° C for 5-10 minutes, and then promoted to the double-stage twin-screw extruder, air cooling in the temperature range of 120-150 ° C Extrude and granulate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com