Warm-white high-color-rendering-index fluorescent ceramic for high-power LED/LD illumination, as well as preparation method and application thereof

A fluorescent ceramic, high-power technology, applied in lighting and heating equipment, optical elements used to change the spectral characteristics of emitted light, energy-saving lighting, etc., can solve the problem of light loss of devices, limited luminous efficiency, light decay and color drift, etc. problem, to achieve the effect of enhanced crystal field strength, excellent optical index, and excellent optical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

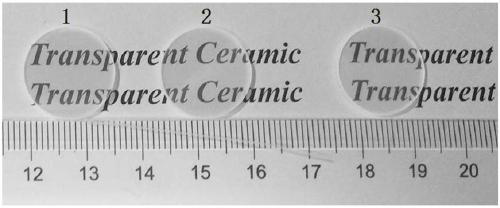

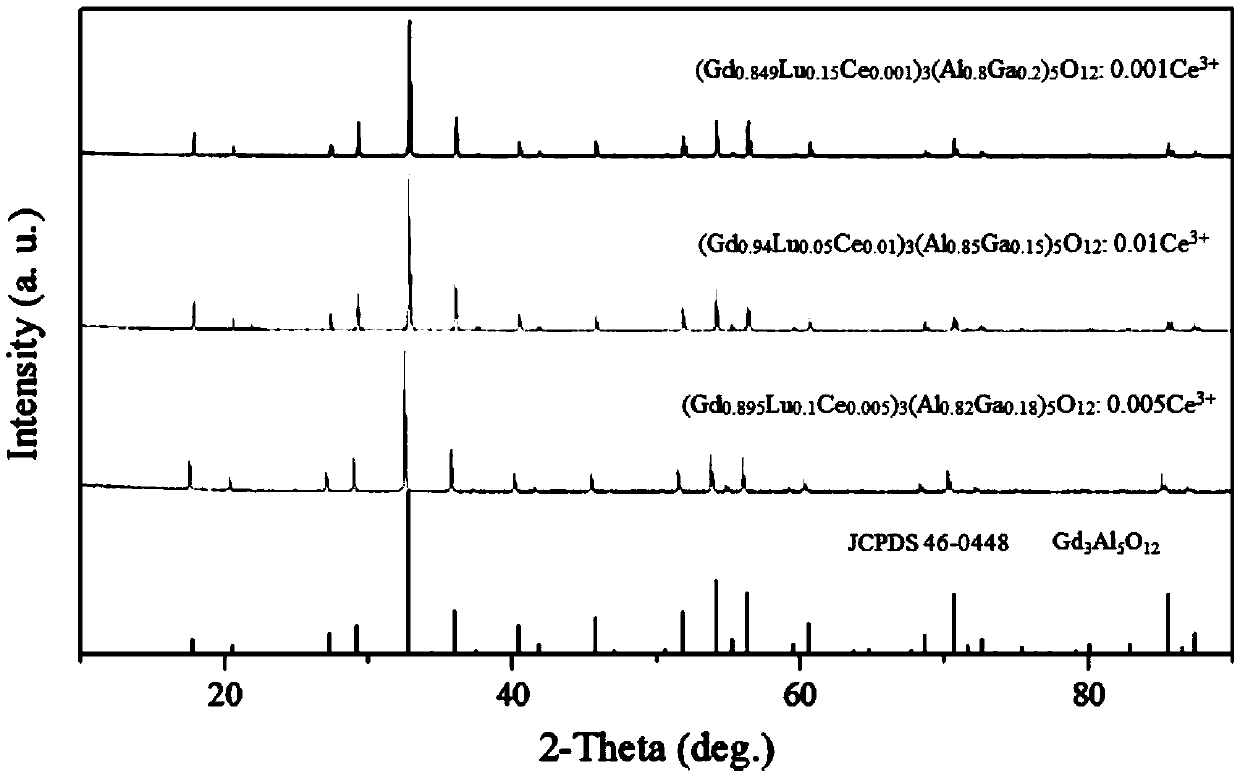

[0041] Embodiment 1: preparation (Gd 0.849 Lu 0.15 Ce 0.001 ) 3 (Al 0.8 Ga 0.2 ) 5 o 12 :0.001Ce 3+

[0042] (1) Set the target product (Gd 0.849 Lu 0.15 Ce 0.001 ) 3 (Al 0.8 Ga 0.2 ) 5 o 12 :0.001Ce 3+ The mass is 60g, and aluminum oxide, gadolinium oxide, lutetium oxide, gallium oxide and cerium oxide are respectively weighed as raw material powder according to the stoichiometric ratio of each element in the chemical formula; raw material powder, 0.006g calcium oxide, 0.06g PEI, 28.125 1g of absolute ethanol and 1.875g of methyl ethyl ketone were mixed, and 240g of 2mm alumina balls were added to carry out the first-stage ball milling in a 250mm ball mill jar, the ball milling speed was 300r / min, and the ball milling time was 10h;

[0043] (2) Add 1.2g plasticizer S160 and 9g binding agent PVB to the slurry obtained by the first stage ball milling, carry out the second stage ball milling, the ball milling speed is 250r / min, and the ball milling time is 10h; ...

Embodiment 2

[0052] Embodiment 2: preparation (Gd 0.94 Lu 0.05 Ce 0.01 ) 3 (Al 0.85 Ga 0.15 ) 5 o 12 :0.01Ce 3+

[0053] (1) Set the target product (Gd 0.94 Lu 0.05 Ce 0.01 ) 3 (Al 0.85 Ga 0.15 ) 5 o 12 :0.01Ce 3+ The mass is 60g. According to the stoichiometric ratio of each element in the chemical formula, alumina, gadolinium oxide, lutetium oxide, gallium oxide and cerium oxide are respectively weighed as raw material powder; raw material powder, 0.12g magnesium oxide, 0.06g zirconia, 4.8g of PEG, 12.5g of absolute ethanol and 2.5g of methyl ethyl ketone were mixed, and 120g of 30mm zirconia balls were added to carry out the first stage of ball milling in a 250mm ball mill jar, the ball milling speed was 120r / min, and the ball milling time was 40h;

[0054] (2) Add 6g plasticizer S160 and 1.8g binding agent PVB to the slurry obtained by the first stage ball milling, carry out the second stage ball milling, the ball milling speed is 120r / min, and the ball milling time is 4...

Embodiment 3

[0063] Embodiment 3: preparation (Gd 0.895 Lu 0.1 Ce 0.005 ) 3 (Al 0.82 Ga 0.18 ) 5 o 12 :0.005Ce 3+

[0064] (1) Set the target product (Gd 0.895 Lu 0.1 Ce 0.005 ) 3 (Al 0.82 Ga 0.18 ) 5 o 12 :0.005Ce 3+ The mass is 60g. According to the stoichiometric ratio of each element in the chemical formula, alumina, gadolinium oxide, lutetium oxide, gallium oxide and cerium oxide are respectively weighed as raw material powder; raw material powder, 0.12g silicon oxide, 0.36g NP-10 , 18g of absolute ethanol and 2g of methyl ethyl ketone, add 150g of zirconia balls with a diameter of 30mm and carry out the first stage of ball milling in a 250mm ball mill jar, the ball milling speed is 120r / min, and the ball milling time is 20h;

[0065] (2) Add 3g plasticizer S160 and 6g binder PVB to the slurry obtained by ball milling in the first stage, carry out ball milling in the second stage, the ball milling speed is 150r / min, and the ball milling time is 20h;

[0066] (3) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com