Method for reducing surface defects of microstructured silicon-based photodetector and photodetector

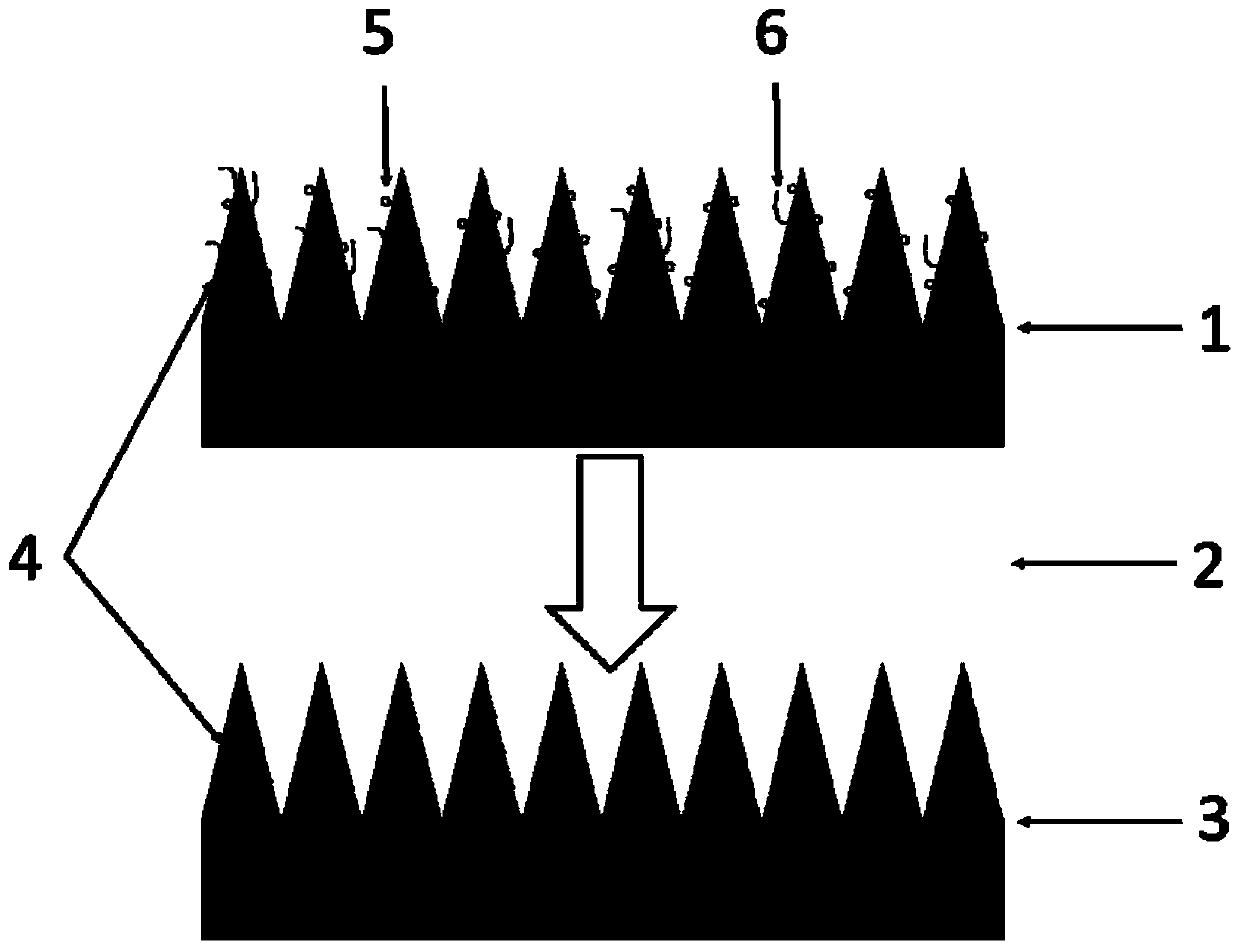

A photodetector and microstructure technology, applied in the field of photodetection, can solve the problems of less suppression methods, affecting the performance of silicon-based detectors, affecting the performance characteristics of semiconductor materials, etc., to achieve the reduction of roughness, wide applicability and application potential, The effect of microstructural morphology improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

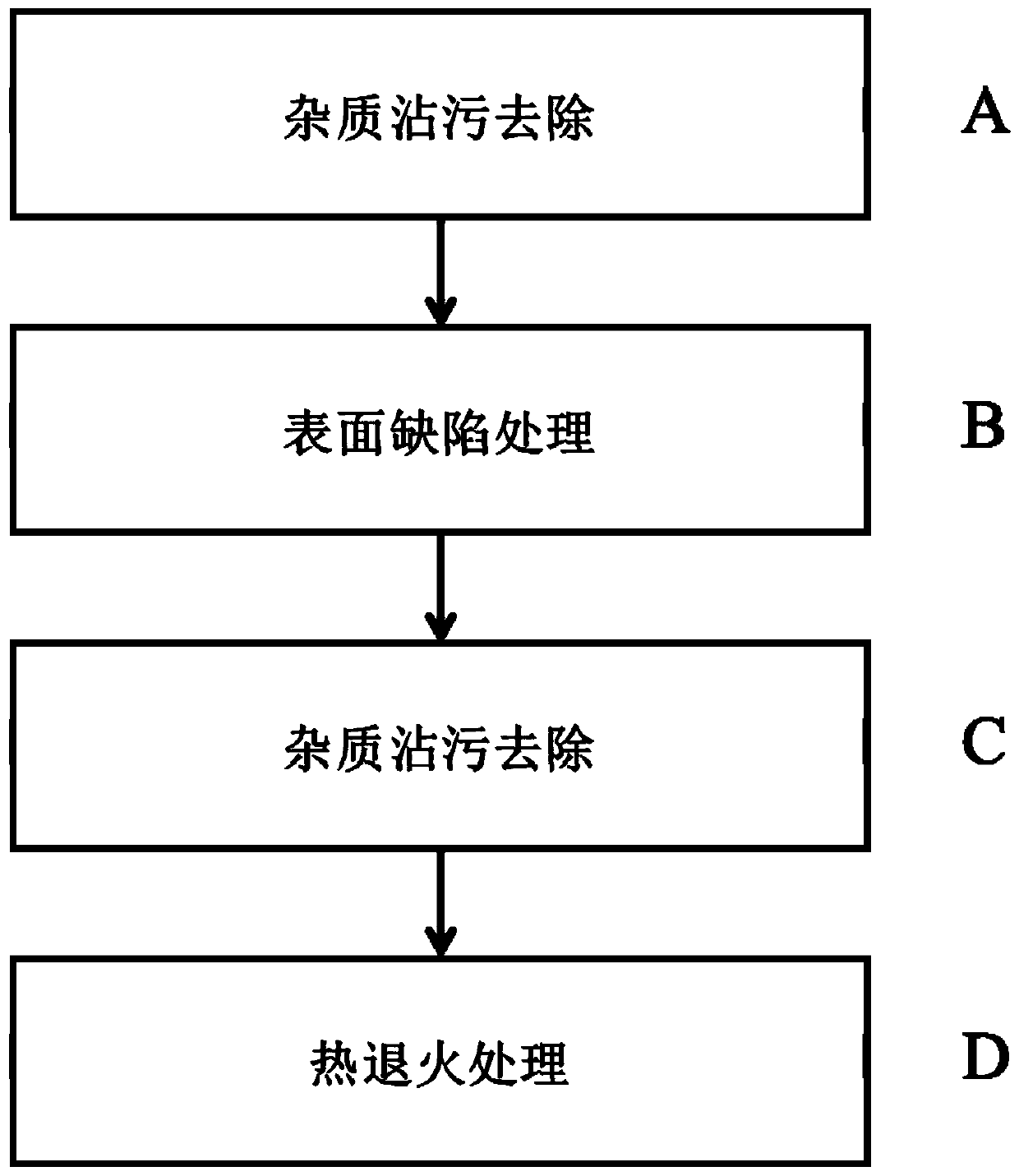

[0039] 1) with H 2 SO 4 :H 2 o 2 =1:3; the ratio of hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) is respectively configured with chemical cleaning agent and functional solvent;

[0040] 2) Place the microstructure silicon-based photodetector irradiated by the femtosecond laser in a special atmosphere in the H 2 SO 4 :H 2 o 2 = In the chemical cleaning agent with a ratio of 1:3, heat to 80 degrees for 15 minutes, take it out and rinse it with deionized water;

[0041] 3) Use hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) to remove the oxide layer on the surface of the microstructured silicon-based photodetector for 10 seconds;

[0042] 4) Perform RIE treatment on the microstructure silicon-based photodetector, the etching gas is SF6, the gas flow rate is 30sccm, the etching power is 30W, and the etching time is 60s;

[0043] 5) Use H 2 SO 4 :H 2 o 2 = 1:3 ratio of chemical cleaning agent to clean th...

Embodiment 2

[0046] 1) with H 2 SO 4 :H 2 o 2 =1:3; the ratio of hydrofluoric acid corrosion inhibitor (1:50 ratio slow-release corrosion agent) is respectively configured with chemical cleaning agent and functional solvent;

[0047] 2) Place the microstructure silicon-based photodetector irradiated by the femtosecond laser in a special atmosphere in the H 2 SO 4 :H 2 o 2 = In the chemical cleaning agent with a ratio of 1:3, heat to 80 degrees for 15 minutes, take it out and rinse it with deionized water;

[0048] 3) Use hydrofluoric acid corrosion inhibitor (1:50 ratio slow-release corrosion agent) to remove the oxide layer on the surface of the microstructured silicon-based photodetector for 5 to 10 seconds;

[0049] 4) Perform RIE treatment on the microstructure silicon-based photodetector, and the etching gas is NF 3 , the gas flow rate is 60sccm, the etching power is 50W, and the etching time is 30s;

[0050] 5) Use H 2 SO 4 :H 2 o 2 = 1:3 ratio of chemical cleaning agent...

Embodiment 3

[0053] 1) with H 2 SO 4 :H 2 o 2 =1:2; the ratio of hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) is respectively configured with chemical cleaning agent and functional solvent;

[0054] 2) Place the microstructure silicon-based photodetector irradiated by the femtosecond laser in a special atmosphere in the H 2 SO 4 :H 2 o 2 =In the chemical cleaning agent with a ratio of 1:2, heat to 80 degrees for 15 minutes, take it out and rinse it with deionized water;

[0055] 3) Use hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) to remove the oxide layer on the surface of the microstructured silicon-based photodetector for 10s;

[0056] 4) Perform RIE treatment on the microstructure silicon-based photodetector, and the etching gas is SF 6 , the gas flow rate is 60sccm, the etching power is 30W, and the etching time is 200s;

[0057] 5) Use H 2 SO 4 :H 2 o 2 = 1:2 ratio of chemical cleaning agent to clean th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com