Method for reducing surface defects of microstructured silicon-based photodetector and photodetector

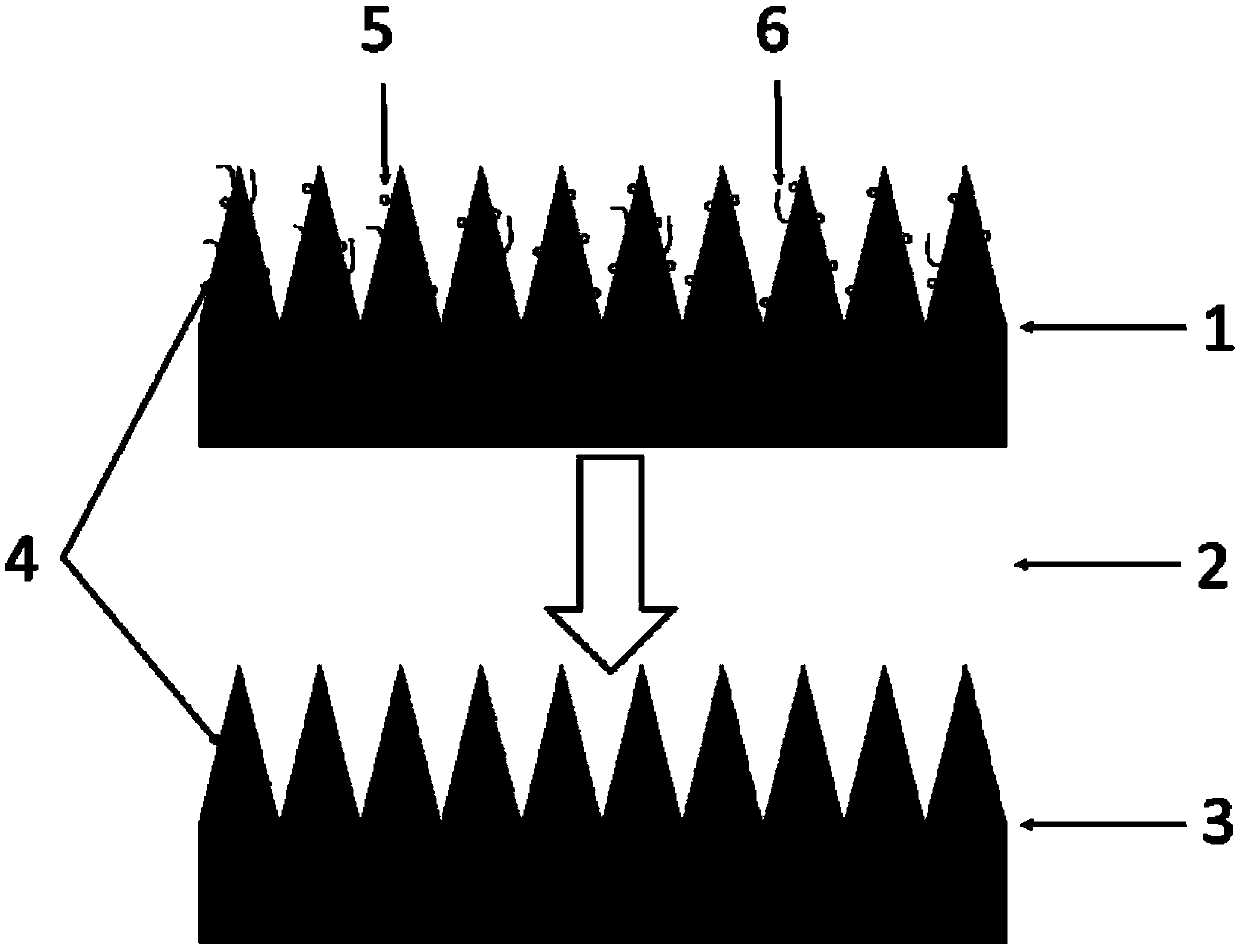

A photodetector and microstructure technology, applied in the field of photodetection, can solve the problems of less suppression methods, affecting the performance characteristics of semiconductor materials, and affecting the performance of silicon-based detectors, so as to reduce roughness, wide applicability and application potential, The effect of microstructural morphology improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

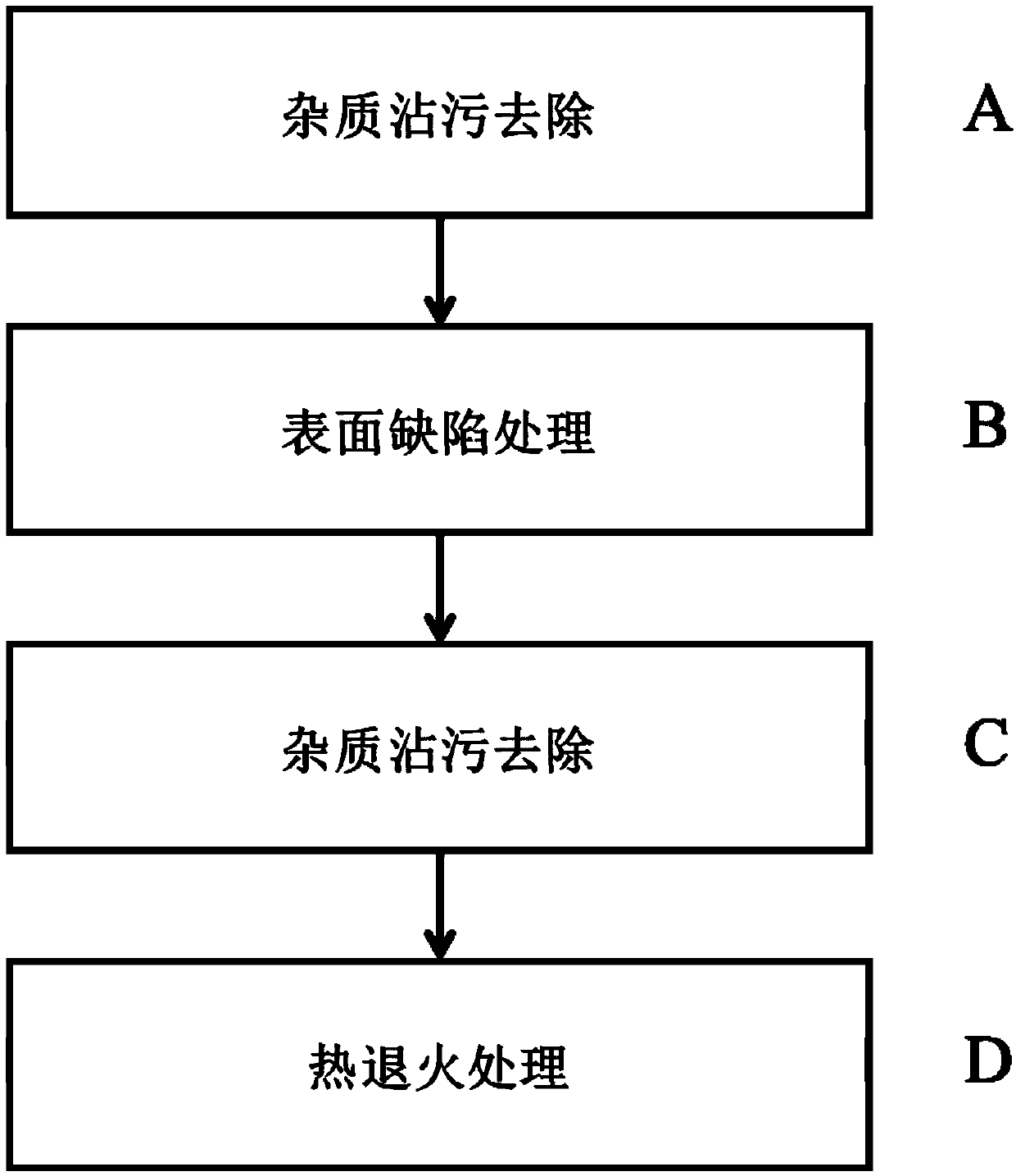

[0039] 1) with H 2 SO 4 :H 2 o 2 =1:3; the ratio of hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) is respectively configured with chemical cleaning agent and functional solvent;

[0040] 2) Place the microstructure silicon-based photodetector irradiated by the femtosecond laser in a special atmosphere in the H 2 SO 4 :H 2 o 2 = In the chemical cleaning agent with a ratio of 1:3, heat to 80 degrees for 15 minutes, take it out and rinse it with deionized water;

[0041] 3) Use hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) to remove the oxide layer on the surface of the microstructured silicon-based photodetector for 10 seconds;

[0042] 4) Perform RIE treatment on the microstructure silicon-based photodetector, the etching gas is SF6, the gas flow rate is 30sccm, the etching power is 30W, and the etching time is 60s;

[0043] 5) Use H 2 SO 4 :H 2 o 2 = 1:3 ratio of chemical cleaning agent to clean th...

Embodiment 2

[0046] 1) with H 2 SO 4 :H 2 o 2 =1:3; the ratio of hydrofluoric acid corrosion inhibitor (1:50 ratio slow-release corrosion agent) is respectively configured with chemical cleaning agent and functional solvent;

[0047] 2) Place the microstructure silicon-based photodetector irradiated by the femtosecond laser in a special atmosphere in the H 2 SO 4 :H 2 o 2 = In the chemical cleaning agent with a ratio of 1:3, heat to 80 degrees for 15 minutes, take it out and rinse it with deionized water;

[0048] 3) Use hydrofluoric acid corrosion inhibitor (1:50 ratio slow-release corrosion agent) to remove the oxide layer on the surface of the microstructured silicon-based photodetector for 5 to 10 seconds;

[0049] 4) Perform RIE treatment on the microstructure silicon-based photodetector, and the etching gas is NF 3 , the gas flow rate is 60sccm, the etching power is 50W, and the etching time is 30s;

[0050] 5) Use H 2 SO 4 :H 2 o 2 = 1:3 ratio of chemical cleaning agent...

Embodiment 3

[0053] 1) with H 2 SO 4 :H 2 o 2 =1:2; the ratio of hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) is respectively configured with chemical cleaning agent and functional solvent;

[0054] 2) Place the microstructure silicon-based photodetector irradiated by the femtosecond laser in a special atmosphere in the H 2 SO 4 :H 2 o 2 =In the chemical cleaning agent with a ratio of 1:2, heat to 80 degrees for 15 minutes, take it out and rinse it with deionized water;

[0055] 3) Use hydrofluoric acid corrosion inhibitor (1:20 ratio slow-release corrosion agent) to remove the oxide layer on the surface of the microstructured silicon-based photodetector for 10s;

[0056] 4) Perform RIE treatment on the microstructure silicon-based photodetector, and the etching gas is SF 6 , the gas flow rate is 60sccm, the etching power is 30W, and the etching time is 200s;

[0057] 5) Use H 2 SO 4 :H 2 o 2 = 1:2 ratio of chemical cleaning agent to clean th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com