A groove-type lateral pressure-resistant region with strontium titanate film

A technology of lateral withstand voltage and strontium titanate, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of low breakdown voltage, achieve high breakdown voltage and optimize the contradictory relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

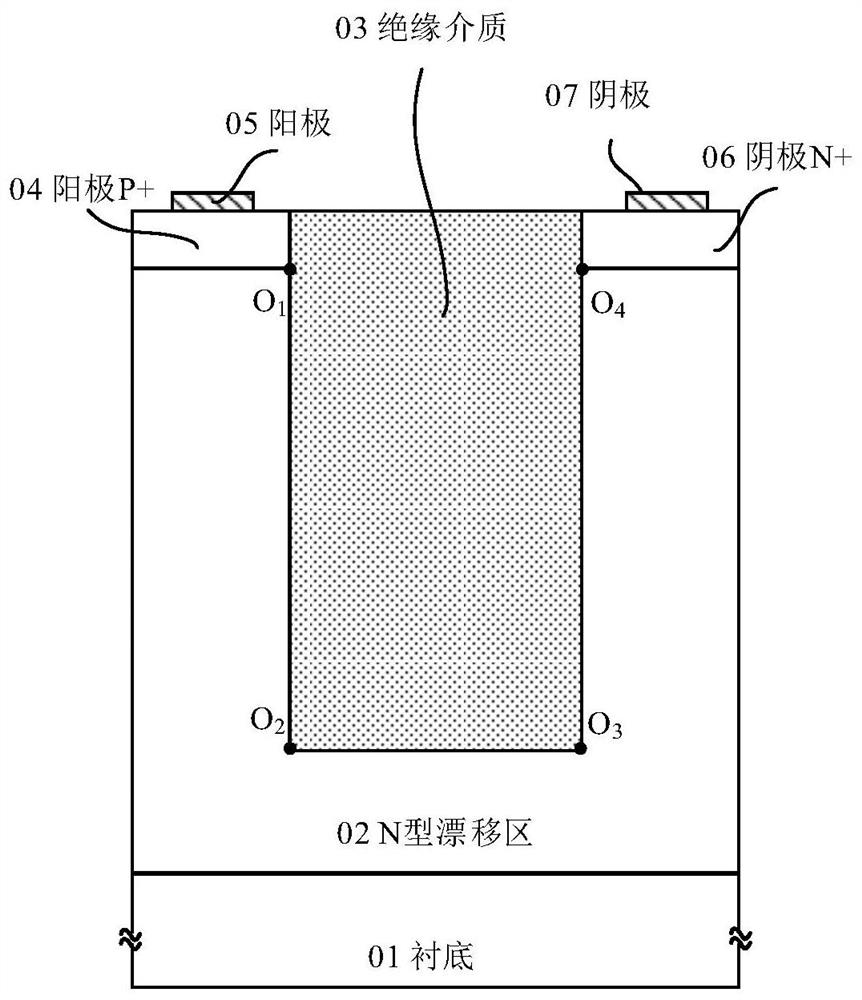

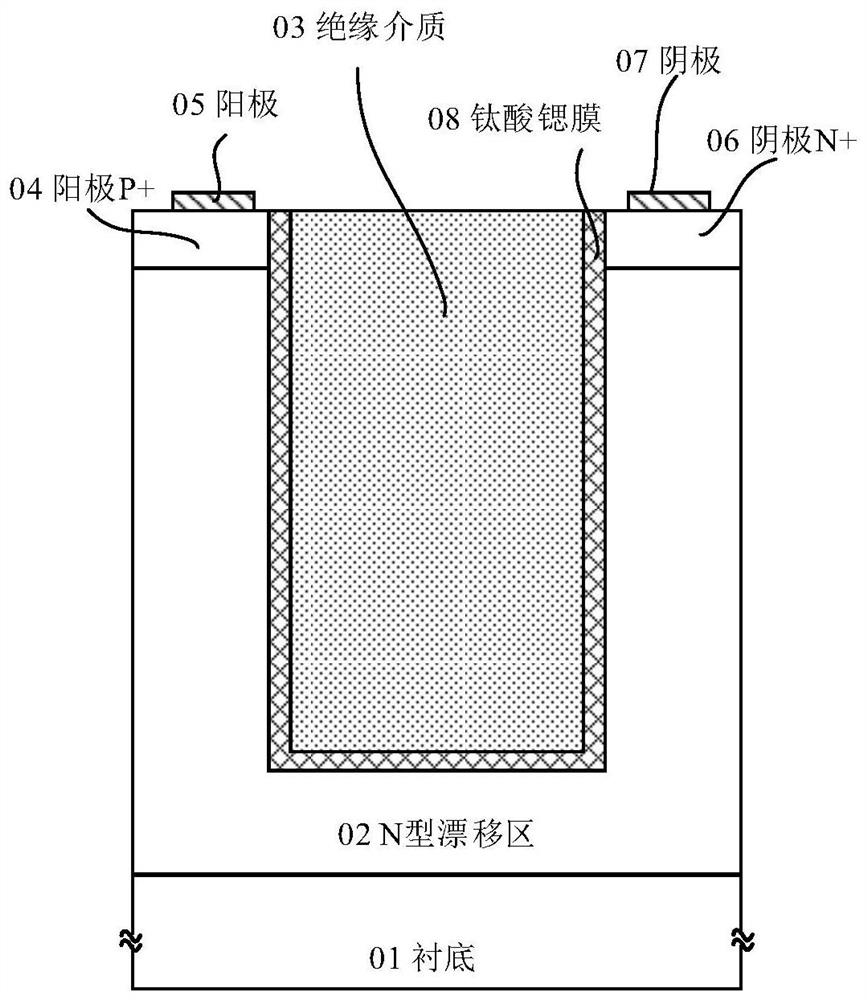

[0026] This embodiment provides a groove-shaped lateral pressure-resistant region with a strontium titanate film, the structure of which is as follows figure 2 Shown; including substrate (01), N-type drift region (02), insulating medium (03), anode P+ (04), anode (05), cathode N+ (06), cathode (07) and strontium titanate film (08); the N-type drift region (02) is located above the substrate (01); deep grooves are provided in the N-type drift region (02), and the insulating medium (03) is filled in the deep grooves; the anode P+ (04) is located above the N-type drift region (03) and on the left side of the insulating medium (04), and an anode (05) is arranged above the anode P+ (04); the cathode N+ (06) is located in the N-type drift region (03) Above and on the right side of the insulating medium (04), the cathode (07) is set above the cathode N+ (06); the strontium titanate film (08) is between the insulating medium (03) and the N-type drift region (02), the anode P+ ( 04) ...

Embodiment 2

[0030] This embodiment provides a groove-shaped lateral pressure-resistant region with a superjunction structure and a strontium titanate film, the structure of which is as follows Figure 4 shown; the difference from Example 1 is that the groove-type lateral voltage withstand region also includes a P-type drift region (09), and the P-type drift region (09) is arranged in the N-type drift region (03), Located under the anode P+ (04), and in contact with the anode P+ (04) and the strontium titanate film (08); the P-type drift region (09) is charged with the N-type drift region under the anode P+ (04) compensate.

[0031] The increase of the P-type drift region in this embodiment is conducive to the formation of a super junction structure under the anode P+, which balances the charges that are difficult to be constrained by the new capacitance due to the proximity of the anode P+ in Example 1, thereby obtaining a more ideal electric field distribution.

[0032] With the help ...

Embodiment 3

[0036] This embodiment provides an N-channel LDMOS using a trench-type lateral withstand voltage region with a strontium titanate film, the basic structure of which is as follows Image 6 Shown; the structure uses a trench gate and SOI substrate.

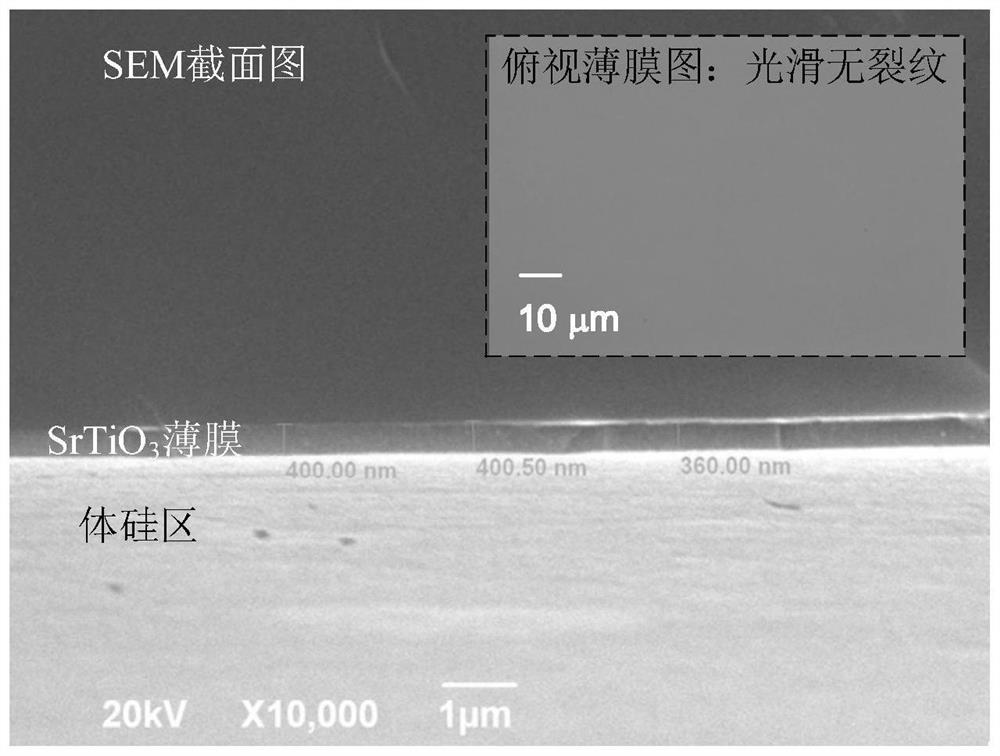

[0037] The main manufacturing process of N-channel LDMOS using the existing groove-type lateral withstand voltage region includes steps such as wafer preparation, groove etching, insulating dielectric filling the groove, chemical mechanical polishing, and active region production, such as Figure 7 shown. In contrast, this embodiment only needs to deposit a certain thickness of strontium titanate material before depositing the insulating medium. Besides, no redundant mask or other operations are required, so no complicated process changes are caused.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com