Method for chemical plating on surface of polymer film

A technology of polymer film and surface chemistry, which is applied in the field of electroless plating, can solve problems such as environmental pollution and surface damage, and achieve the effect of reducing cost and good activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

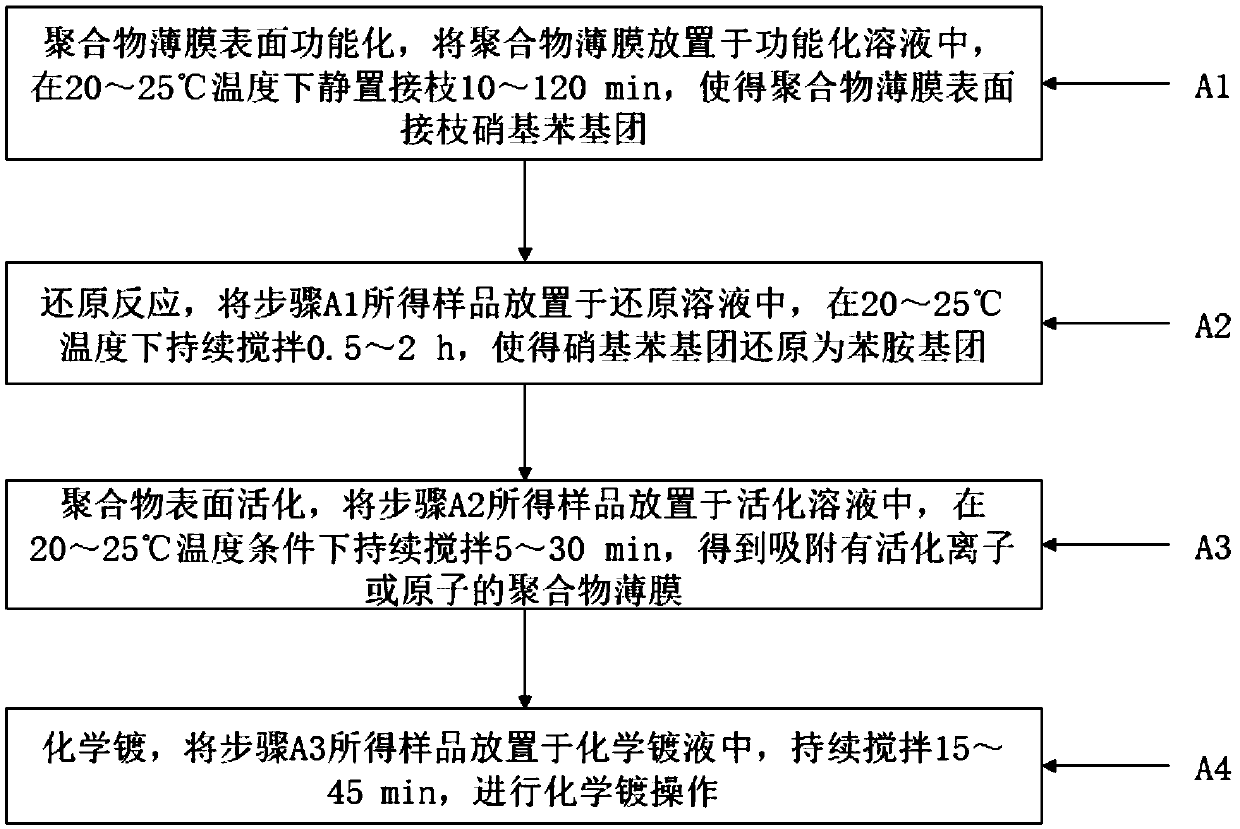

[0039] refer to figure 1 , present embodiment provides a kind of method of electroless plating on polymer film surface, polymer film can be polymethyl methacrylate (PMMA), polymethacrylic acid (PMAA), polymethacrylimide (PMI) , polyethylene terephthalate (PET), polyamide (PA), polypropylene (PP), polyvinyl chloride (PVC), polyvinyl alcohol (PVA) and most organic films, and the thickness of the polymer film It can be as low as several hundred nanometers, can be deposited on a metal or semiconductor substrate, and the polymer film can be prepared by conventional methods in the art. The method of this embodiment includes:

[0040] A1: The surface of the polymer film is functionalized, the polymer film is placed in a functional solution, and the grafting is allowed to stand at a temperature of 20-25°C for 10-120 minutes, so that the surface of the polymer film is grafted with nitrophenyl groups;

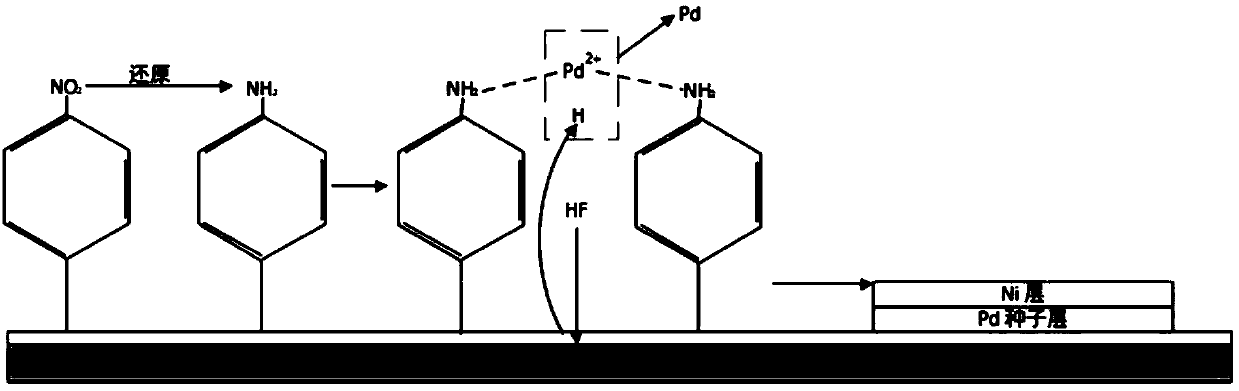

[0041] A2: Reduction reaction, place the sample obtained in step A1 in the reducin...

Embodiment 2

[0060] The substrate is a silicon wafer, and the surface of a polymethyl methacrylate (PMMA) film with a thickness of 200nm is chemically plated with Ni-P alloy. The specific steps are:

[0061] 1. Preparation of PMMA film: use acetone, alcohol and deionized water respectively for a size of 1×2cm 2 After the silicon chip was ultrasonically cleaned, it was immersed in an HF solution with a volume ratio concentration of 5% for Si–H treatment for 3 minutes, and the silicon chip was placed in the prepared grafting solution, and the grafting reaction was carried out at room temperature for 45 minutes. Afterwards, they were ultrasonically cleaned with deionized water and dried. A PMMA polymer film with a thickness of about 200 nm was obtained on the surface of the silicon wafer. The preparation method of the above-mentioned grafting solution is as follows: first, add 50 mL of deionized water into a beaker, then add 0.1 g of sodium lauryl sulfate, 1 mL of fluoroboric acid, 0.5 mL of...

Embodiment 3

[0073] Substrate is copper, and thickness is the polymethacrylic acid (PMAA) film surface electroless Ni-P alloy plating of 1 μm, and its step is:

[0074] 1. Preparation of PMAA film: the size is 1×2cm 2 The copper sheet was placed in the chemical grafting solution of PMAA, and after the grafting reaction was carried out at room temperature for 30 minutes, it was ultrasonically cleaned with deionized water and dried. A PMAA polymer film with a thickness of about 150 nm was obtained on the surface of the copper sheet. The preparation method of the grafting solution is as follows: first, add 50 mL of deionized water into the beaker, then add 0.1 g of sodium lauryl sulfate, 1 mL of fluoroboric acid, 0.5 mL of hydrofluoric acid, and 2 mL of formazan in sequence under magnetic stirring. Acrylic acid and 0.1 g of diazonium p-nitrobenzenetetrafluoroborate were stirred until a clear solution was obtained.

[0075] 2. Set the size to 1×2cm 2 The samples were ultrasonically cleaned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com