Self-repair organosilicon material preparation method

An organosilicon and three-necked flask technology is applied in the field of self-healing organosilicon material preparation, which can solve the problems of inability to achieve mass production, complex synthesis process, poor mechanical properties, etc. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

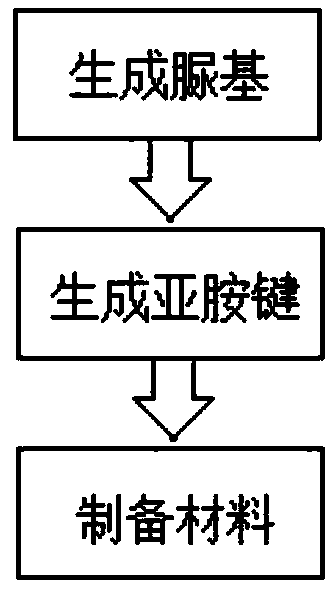

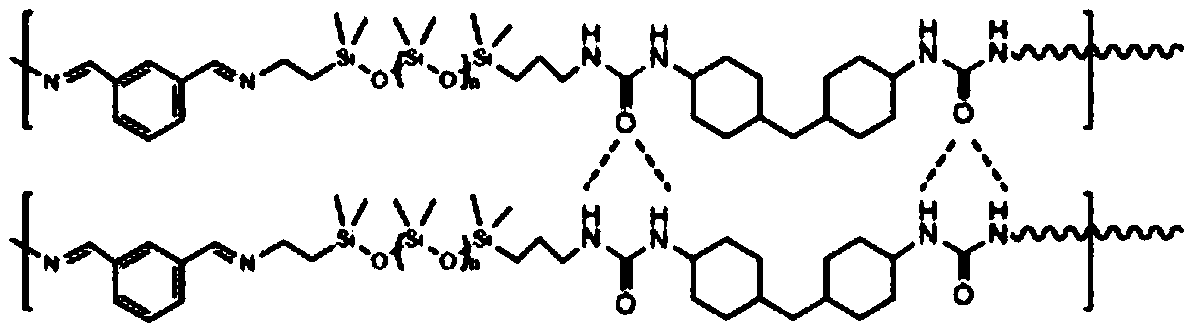

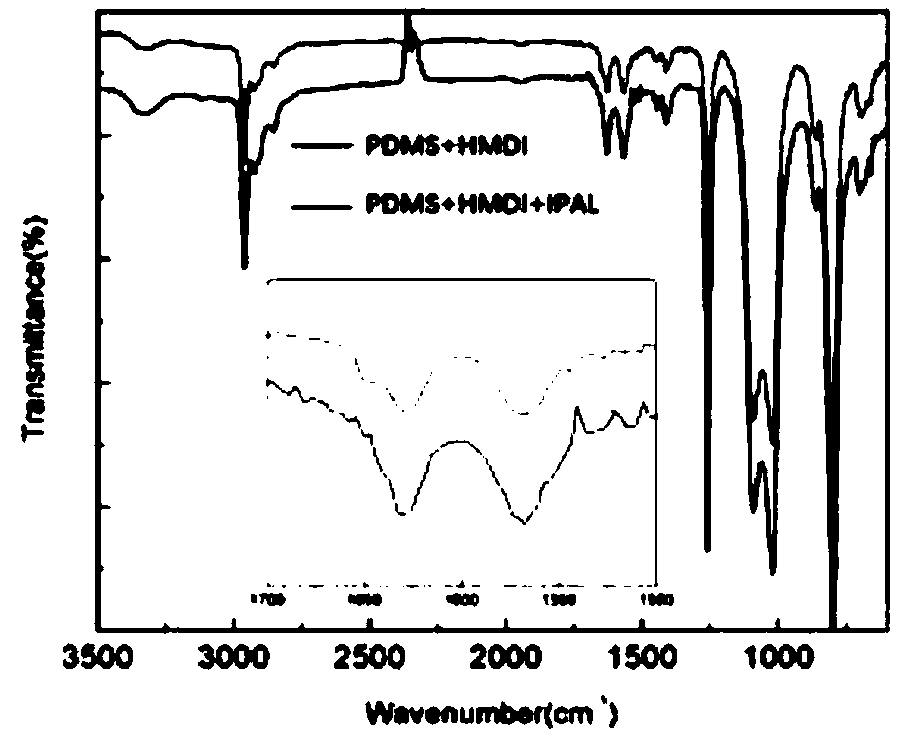

[0024] The process of the preparation method of the self-healing silicone material involved in this embodiment includes three steps of generating urea groups, generating imine bonds and preparing materials:

[0025] (1) Generating urea groups: add 20 g of amino-terminated polydimethylsiloxane (PDMS) and 100 mL of tetrahydrofuran (THF) to a 500 mL three-necked flask, stir evenly, and feed nitrogen into the three-necked flask to get rid of the three-necked flask. Air, add 1.31g of dicyclohexylmethane diisocyanate dropwise into the three-necked flask with a syringe, under nitrogen atmosphere, 90°C oil bath, magnetic stirring, condensing and reflux for 20h, PDMS and dicyclohexylmethane diisocyanate react to form urea groups;

[0026] The molar ratio of PDMS to dicyclohexylmethane diisocyanate is 2:1,

[0027] (2) Generation of imine group: add 0.67g of isophthalaldehyde powder into the three-necked flask, and after magnetic stirring reaction at room temperature for 3 hours, raise ...

Embodiment 2

[0031] The process of the preparation method of the self-healing silicone material involved in this embodiment includes three steps of generating urea groups, generating imine bonds and preparing materials:

[0032] (1) Generating urea groups: add 20 g of amino-terminated polydimethylsiloxane (PDMS) and 100 mL of tetrahydrofuran (THF) to a 500 mL three-necked flask, stir evenly, and feed nitrogen into the three-necked flask to get rid of the three-necked flask. Air, add 1.01g of hexamethylene diisocyanate dropwise into the three-necked flask with a syringe, under nitrogen atmosphere, 80°C oil bath, magnetic stirring, condensing and reflux for 30h, PDMS and hexamethylene diisocyanate react to form urea groups;

[0033] The molar ratio of PDMS to hexamethylene diisocyanate is 2:1.2,

[0034] (2) Generation of imine groups: add 0.54 g of phthalaldehyde powder to a three-necked flask, and after magnetically stirring for 5 hours at room temperature, raise the temperature to 60° C. ...

Embodiment 3

[0038] The process of the preparation method of the self-healing silicone material involved in this embodiment includes three steps of generating urea groups, generating imine bonds and preparing materials:

[0039] (1) Generating urea groups: add 20 g of amino-terminated polydimethylsiloxane (PDMS) and 100 mL of tetrahydrofuran (THF) to a 500 mL three-necked flask, stir evenly, and feed nitrogen into the three-necked flask to get rid of the three-necked flask. Air, add 1.11g of isophorone diisocyanate dropwise into the three-necked flask with a syringe, under nitrogen atmosphere, 110°C oil bath, magnetic stirring, condensing and reflux for 12h, PDMS and isophorone diisocyanate react to form urea groups;

[0040] The molar ratio of PDMS to isophorone diisocyanate is 2:1,

[0041] (2) Generation of imine groups: Add 0.67g of terephthalaldehyde powder into a three-necked flask, and after magnetically stirring at room temperature for 4 hours, raise the temperature to 70°C and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com