Environment-friendly foamed high-performance concrete and preparation method thereof

A high-performance concrete, environmentally friendly technology, applied in the field of concrete, can solve the problems of low thermal insulation and waterproof performance of concrete, difficult application of ordinary concrete, etc., and achieve the effects of improving waterproof performance, improving waterproof performance, and improving thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

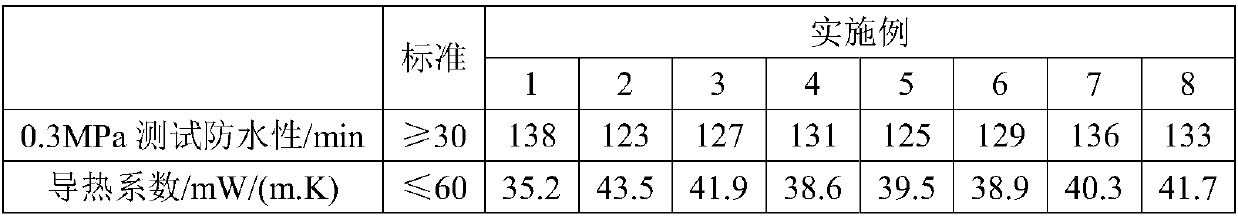

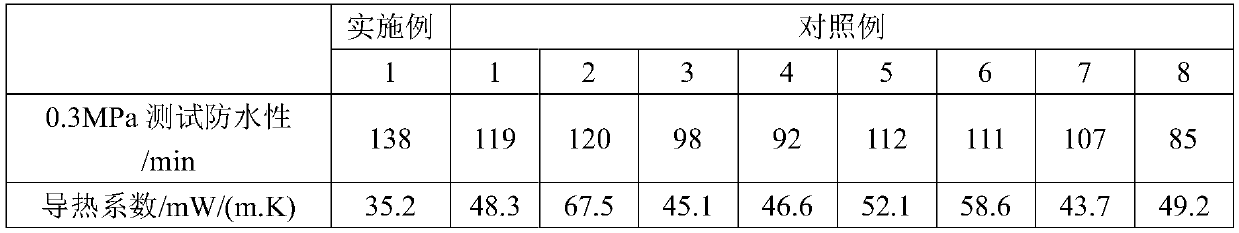

Examples

Embodiment 1

[0021] A kind of environment-friendly foaming high-performance concrete, its preparation method comprises the following steps:

[0022] (1) Add 39 parts of tetrabutyl titanate and 66 parts of ethanol into the reaction kettle, the stirring speed is 75r / min, the reaction temperature is 35°C for 35min, and the product is mixed with 16.5 parts of stearic acid and 18 parts of oleic acid , 37.6 parts of polyoxyethylene stearate SG-12, 9.3 parts of water and 8.8 parts of glycerin mixture were transferred to a hydrothermal reaction kettle, and the hydrothermal reaction was maintained at a system hydrothermal reaction temperature of 90°C for 1 hour, and the temperature of the hydrothermal reaction kettle was Heat up to 145°C for hydrothermal reaction for 4 hours, the product is vacuum-dried at 68°C and -0.06MPa, the product is heat-treated at 100°C for 1 hour, 200°C for 1 hour, 300°C for 1 hour, 400°C for 2 hours, 500°C for 2 hours, and 600°C 3h, grinding, the product was washed with 5...

Embodiment 2

[0028] A kind of environment-friendly foaming high-performance concrete, its preparation method comprises the following steps:

[0029] (1) Add 39 parts of tetrabutyl titanate and 58 parts of ethanol into the reaction kettle, the stirring speed is 75r / min, the reaction temperature is 35°C for 35min, and the product is mixed with 13 parts of stearic acid and 13 parts of oleic acid , 29 parts of polyoxyethylene stearate SG-12, 6 parts of water and 7 parts of glycerin mixture were transferred to a hydrothermal reaction kettle, and the hydrothermal reaction was maintained at a system hydrothermal reaction temperature of 85°C for 2 hours, and the temperature of the hydrothermal reaction kettle Heat up to 132°C for hydrothermal reaction for 6 hours, the product is vacuum-dried at 68°C and -0.06MPa, the product is heat-treated at 100°C for 1 hour, 200°C for 1 hour, 300°C for 1 hour, 400°C for 2 hours, 500°C for 2 hours, and 600°C 3h, grinding, the product was washed with 5% acetic ac...

Embodiment 3

[0035] A kind of environment-friendly foaming high-performance concrete, its preparation method comprises the following steps:

[0036] (1) Add 39 parts of tetrabutyl titanate and 70 parts of ethanol into the reaction kettle, the stirring speed is 75r / min, the reaction temperature is 35°C for 35min, and the product is mixed with 25 parts of stearic acid and 21 parts of oleic acid , 41 parts of polyoxyethylene stearate SG-12, 12 parts of water and 15 parts of glycerin are transferred to a hydrothermal reaction kettle, and the hydrothermal reaction is maintained at a temperature of 97°C for 0.5h, and the hydrothermal reaction kettle The temperature was raised to 158°C for hydrothermal reaction for 1 hour, the product was vacuum-dried at 68°C and -0.06 MPa, the product was heat-treated at 100°C for 1 hour, at 200°C for 1 hour, at 300°C for 1 hour, at 400°C for 2 hours, at 500°C for 2 hours, at 600°C heat treatment for 3 hours, grinding, the product was washed with 5% acetic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com