Preparation method of low-wavelength and low-transparency rare earth sulfur-oxygen composite compound

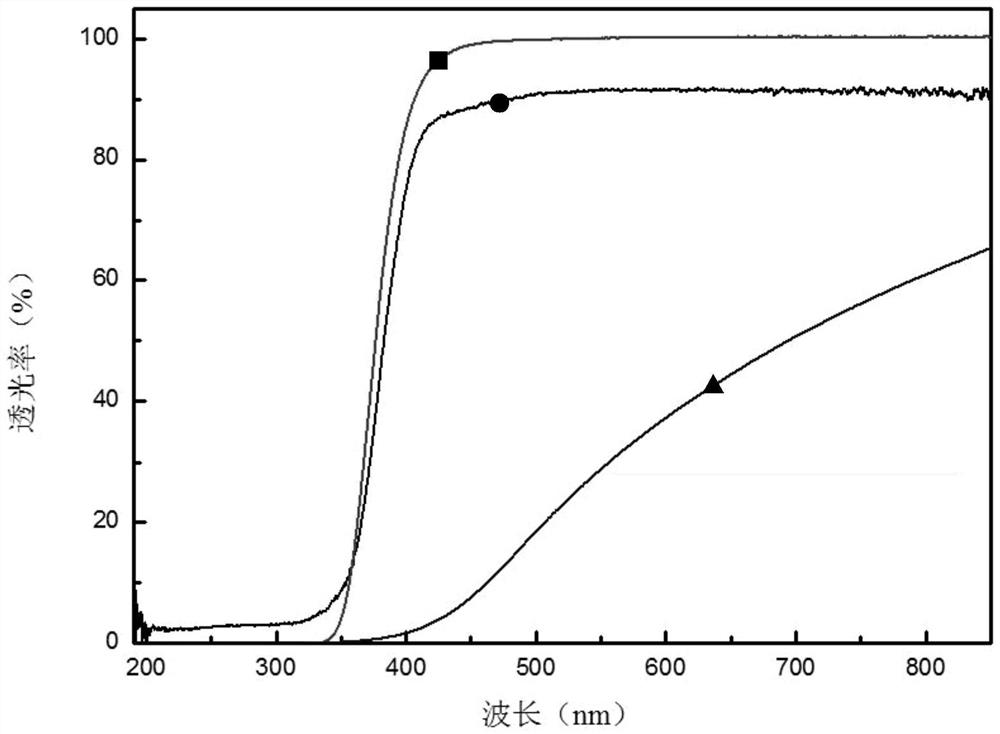

A technology of compound and rare earth chloride salt, which is applied in the field of preparation of low-wavelength and low-transmittance rare-earth sulfur-oxygen complex compounds, can solve the problem of poor shielding effect of ultraviolet rays, achieve good shielding effect, wide shielding range, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The Class A rare earth salt is dissolved in water to form a Class A rare earth salt solution; a class of rare earth salts is a class of rare earth chloride; Class A rare earth chloride is a lanthanum chloride; the concentration of rare earth in the A-rare earth salt solution is 0.2m;

[0033] B-class rare earth salts were dissolved in water to prepare B Rare Earth Salt Solution; B - class rare earth salt is a mass mixture of B-class rare earth chloride and B-class rare earth nitrate; B-class rare earth chloride is chlorinated; B Rare earth nitrate is nitrate; the concentration of rare earth in the B-rare earth salt solution is 0.8 m;

[0034] The precipitant is dissolved in water to prepare a precipitant solution; the precipitant is sodium thiosulfate; the concentration of the precipitant in the precipitant solution is 0.2m;

[0035] Mix the A-class rare earth salt solution, B-class rare earth salt solution, and a precipitating agent solution to prepare a mixed solution; th...

Embodiment 2

[0039] Methods The same embodiments are:

[0040] (1) A class of rare earth chloride is a branch of cerium chloride; the concentration of rare earth in the A-rare earth salt solution is 0.4m;

[0041] (2) B-class rare earth salt is a mixture of mass mixture of B-class rare earth nitrate and B-rare earth sulfate; B-class rare earth nitrate is a mixture of nitrate and nitrate 铽; the B-class rare earth sulfate is sulfuric acid钐 and sulfuricate mixture; the concentration of rare earth in the B-rare earth salt solution is 0.2m;

[0042] (3) The precipitant is ammonium sulfide; the concentration of the precipitant in the precipitant solution is 0.6 m;

[0043] (4) The molar ratio of Class A rare earth salt, B-class B-rare earth salt and precipitant in the mixed solution is 1: 0.05: 0.05; the pH is adjusted to be 3, stirred under 90 ° C for 10 min;

[0044] (5) Roast 10 h at 200 ° C; low-wavelength low-transparent rare earth sulfur-composite compound is a x OS y · B m O n S k Among them,...

Embodiment 3

[0046] (1) A class of rare earth chloride is chlorinated; the concentration of rare earth in the A-class rare earth salt solution is 0.5m;

[0047] (2) B-class rare earth salt is a mass mixture of B-class rare earth chloride, B-class rare earth nitrate and B-rare earth sulfate; B-class rare earth chloride is a cerium chloride; B-rare earth nitrate is a butectic acid B-class rare earth sulfate is sulfate; the concentration of rare earth in the B-rare earth salt solution is 0.9m;

[0048] (3) The precipitant is sodium sulfide; the concentration of the precipitant in the precipitant solution is 1 m;

[0049] (4) The molar ratio of Class A rare earth salt, B rare earth salt and precipitating agent in the mixed solution is 1:20:20; the pH is 4, stirred at 30 ° C.

[0050] (5) calcined at 600 ° C for 1 h; the low wavelength low-transparent rare earth sulfur-oxide compound compound is a x OS y · B m O n S k Where the A is PR, B is Y, EU and SM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com