Method for producing phosphoric acid and low-silicon gypsum by middle-low-grade phosphorus ore

A low-grade, gypsum technology, applied in the direction of chemical instruments and methods, phosphorus compounds, calcium/strontium/barium sulfate, etc., can solve the problems of difficult production of gypsum semi-aqueous method, high water content of gypsum, low concentration of phosphoric acid, etc., to achieve Reuse of water resources, beneficial to recycling, and the effect of improving the quality of phosphate rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

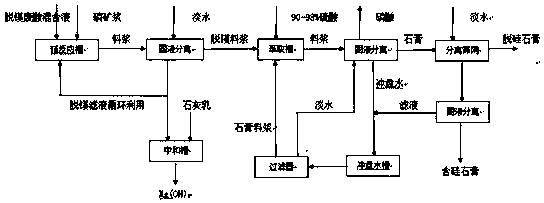

Method used

Image

Examples

Embodiment 1

[0020]1000kg solid content is 70% ore slurry (CO2 content is 5.71%, P2O5 content is 29.21%, MgO content is 2.51%), add a certain proportion of magnesium removal waste liquid (circulation), adjust the initial liquid-solid ratio to be 2: 1. Place in the pretreatment reaction tank and stir continuously at a stirring speed of 100rpm. 1334kg of magnesium removal waste liquid and 445kg of waste acid (the concentration of sulfuric acid is 20%, and the temperature is 45°C) are passed into the dilute acid storage tank for rapid mixing, and then input through the pipeline React with phosphate rock in the pretreatment reaction tank, control the adding speed of sulfuric acid to ensure that the pH value of the reaction liquid phase is between 2.7-3, control the feeding time at 1h, extend the reaction for 0.5h after the feeding is completed, and separate the liquid and solid phases. The CO2 content in the filter cake base was analyzed to be 2.62%, the P2O5 content was 29.02%, and the MgO con...

Embodiment 2

[0022] 1000kg solid content is 70% ore slurry (CO2 content is 4.47%, P2O5 content is 29.19%, MgO content is 2.19%), add a certain proportion of magnesium removal waste liquid (circulation), adjust the initial liquid-solid ratio to be 2: 1. Place in the pretreatment reaction tank and stir continuously at a stirring speed of 100rpm. Put 1045kg of magnesium-removing waste liquid and 348kg of waste acid (the concentration of sulfuric acid is 20%, and the temperature is 45°C) into the dilute acid storage tank for rapid mixing, and pass through the pipeline Input it into the pretreatment reaction tank to react with phosphate rock, control the adding speed of sulfuric acid to ensure that the pH value of the reaction liquid phase is between 2.7-3, control the feeding time at about 1h, extend the reaction for 0.5h after the feeding is completed, and separate the liquid and solid According to phase analysis, the CO2 content in the filter cake base is 2.56%, the P2O5 content is 28.98%, an...

Embodiment 3

[0024] Put 8kg of wet-process phosphate gypsum (with a silicon content of 7.19% and a phosphorus content of 0.61%) into a 65-mesh standard sieve and sieve it under tap water. until the water that comes out from under the sieve is clear. Put the sieve residue, gypsum under the sieve, and the standard sieve together in an oven at 80°C to dry to constant weight, cool to room temperature, weigh and analyze the silicon and phosphorus content in the sieve residue, under the sieve and the original gypsum, and calculate the silicon yield under the sieve. Rate. After the phosphogypsum is sieved, the silicon content in the gypsum under the sieve is 6.27%, and the phosphorus content is 0.50%. The silicon yield of the gypsum under the sieve is 85.04%, and the phosphorus yield is 79.92%, and the sieving obviously reduces the content of silicon and phosphorus in the gypsum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com