Bio-based metal organic framework assembly esterase catalyst, preparation method and application of catalyst in biodiesel synthesis

An organic framework, biodiesel technology, applied in the biological field, can solve problems such as affecting enzyme catalytic activity and enzyme shedding, and achieve the effect of promoting energy substitution, strong stability and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 500mg of adenine in 5mL of boiling water at 100°C, then quickly pour the adenine solution into 20mL of 25°C aqueous solution dissolved in 10mg of thermophilic esterase QLM and 200mg of zinc acetate, and react at room temperature for 48h. After the reaction was completed, the system was centrifuged at 8000r / min for 5min to collect the precipitate, which was washed three times with distilled water, and the freeze-dried powder was the final product QLM@Bio-MOF with a mass of 250mg.

[0026] By a similar method, a bio-based MOF material (me-Bio-MOF) without thermophilic esterase was prepared, except that the thermophilic esterase QLM was not added.

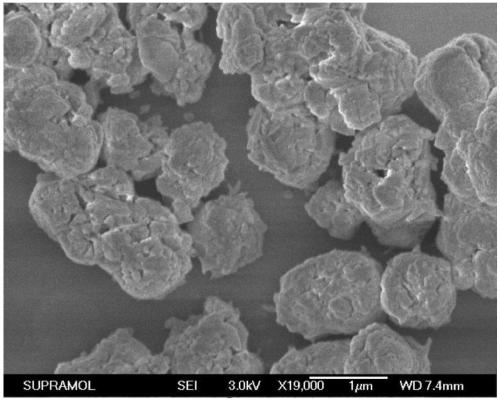

[0027] From figure 1 The scanning electron microscope of the synthesized product found that the QLM@Bio-MOF catalyst synthesized by the above method has regular morphology, and its particle size is between 800nm and 1.5μm.

Embodiment 2

[0029] Dissolve 1000mg of adenine in 10mL of boiling water at 100°C, then quickly pour the adenine solution into 200mL of 100mg of QLM and 400mg of zinc acetate dissolved in an aqueous solution at 25°C. Reaction at room temperature for 48h. After the reaction was completed, the system was centrifuged at 8000r / min for 5min to collect the precipitate, which was washed three times with distilled water, and the freeze-dried powder was the final product QLM@Bio-MOF with a mass of 450mg.

[0030] By a similar method, a bio-based MOF material (me-Bio-MOF) without thermophilic esterase was prepared, except that the thermophilic esterase QLM was not added.

[0031] From figure 2 The results of scanning electron microscopy of the synthesized products found that the QLM@Bio-MOF synthesized by equal proportion of raw material input was regular and uniform in appearance, with particle size between 800nm and 1.5μm. Compared with the QLM@Bio-MOF obtained by the small-batch synthesis met...

Embodiment 3

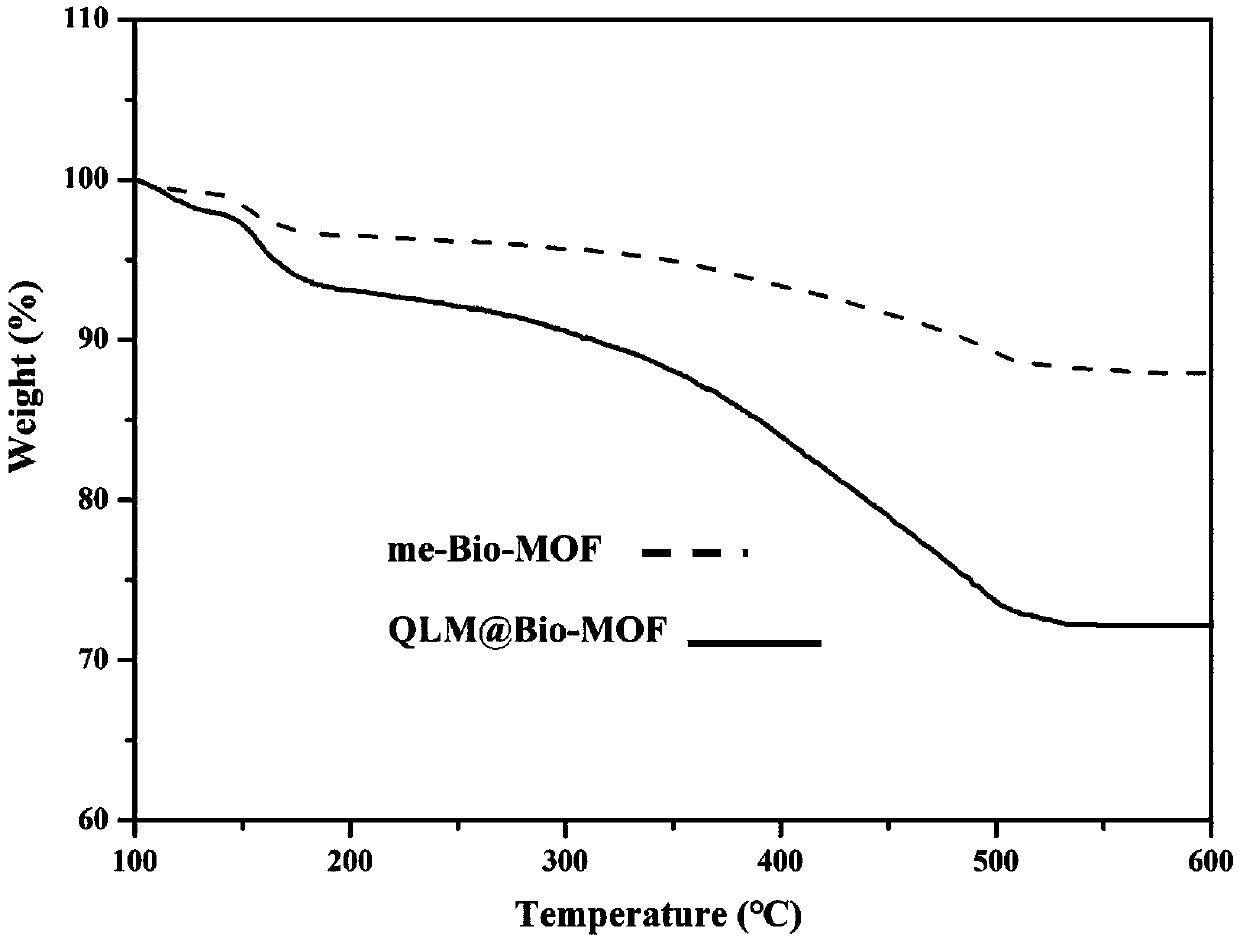

[0033] After fully drying the QLM@Bio-MOF and me-Bio-MOF synthesized in Example 1, the thermogravimetric experiment was carried out. The TAQ500 detection instrument was used to raise the temperature at a rate of 10°C / min in a nitrogen environment. The obtained thermogravimetric curve is as follows: figure 2 shown.

[0034] From image 3 It can be found that QLM@Bio-MOF has obvious weight loss at 200-500 °C, which is about 20% higher than that of me-Bio-MOF, and the higher weight loss represents the weight ratio of the enzyme. Therefore, according to the thermogravimetric curve, it is calculated that the loading amount of QLM in QLM@Bio-MOF is about 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com