Water-based photo-cured elastomeric paint

A light-curing, elastic paint technology, applied in the field of coatings, can solve the problems of long time and high baking temperature, and achieve the effects of less environmental pollution, high coating efficiency and improved production efficiency

Inactive Publication Date: 2011-07-20

ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

View PDF3 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The invention provides a water-based photocurable elastic paint, which solves the problems of high baking temperature and long time after coating of the existing elastic paint

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

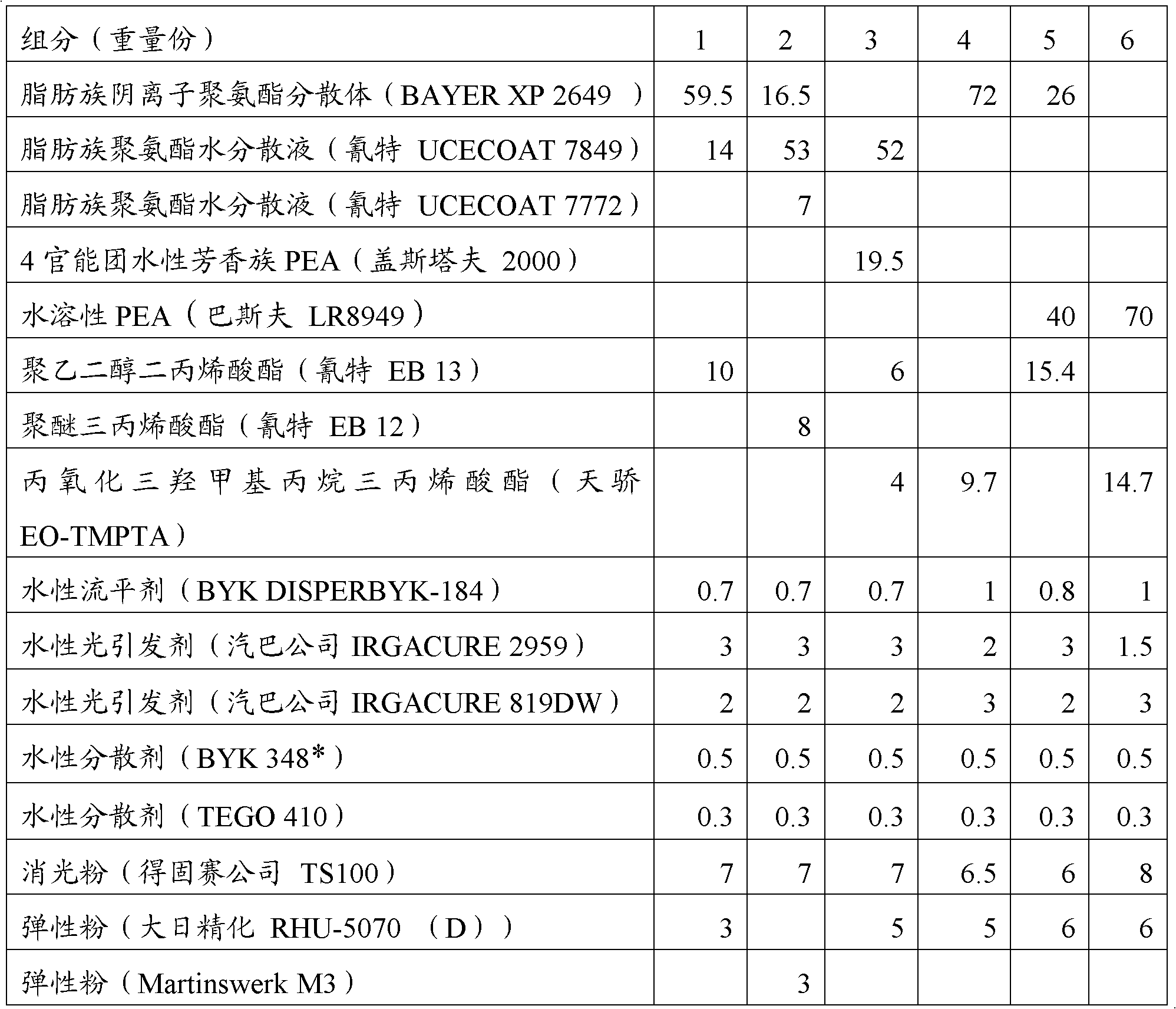

[0026] According to the weight ratio shown in Table 1, first pour the resin, curing monomer and various additives (the additives can be diluted with the monomer first and then slowly added to the resin) into the container, and after dispersing at high speed for 30 minutes, add matting agent and elastic powder, dispersed for 1 hour, and filtered.

[0027] Table 1

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a water-based photo-cured elastomeric paint, which consists of the following components in percentage by weight: 60-80 percent of water-based UV (Ultra Violet) elastic resin, 5-20 percent of water-based UV curing monomer, 1-8 percent of water-based initiator, 0.2-1 percent of water-based flatting agent, 0.2-1 percent of water-based dispersant, 3-9 percent of flatting silica and 1-10 percent of elastic powder. A coating is a water-based UV photo-cured elastomeric paint. Compared with a bi-component coating in the conventional elastic hand paint, the water-based photo-cured elastomeric paint has the advantages of fast curing, high coating efficiency and low environmental pollution.

Description

technical field [0001] The invention relates to a paint, in particular to a water-based photocurable elastic paint. Background technique [0002] Elastic paint, also known as rubber paint and skin-like paint, is a kind of hand-feeling paint. It is often used on the surface of objects that are often touched, giving people a soft texture. It is a popular paint now. Most of the rubber paints currently on the market are two-component high-elastic polyurethane paints, which have high elasticity, friction resistance, impact resistance, and a soft feel. It mainly has the following disadvantages: 1. High energy consumption: the baking time is generally 15-30 minutes, and the baking temperature is 70°C, which requires a lot of heat energy to bake to achieve surface dryness; 2. Low efficiency: the product is surface dry Finally, it needs to be placed at room temperature for a period of time before it can be boxed and packaged; 3. It takes up a lot of space: during the surface-dry sto...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/04C09D171/00C09D4/02C09D7/12

Inventor 陈梦茹刘磊张卫宝张忠良

Owner ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com