Anti-stick polyolefin cable material preparation method

A polyolefin cable material and anti-adhesion technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of large proportion of by-products and reduce product net profit, improve dispersion and save materials and the time in the mixing process, and the effect of improving profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

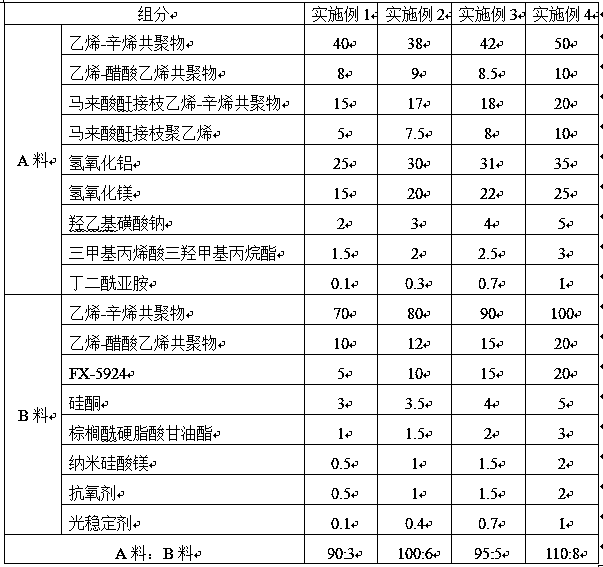

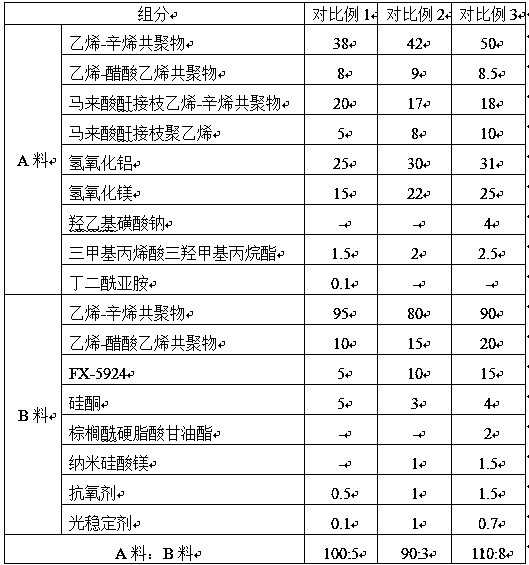

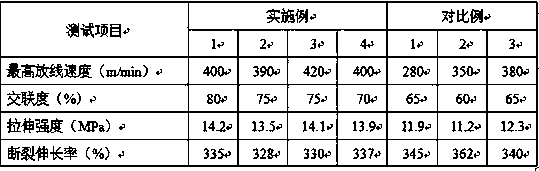

[0020] Embodiment 1~4: a kind of preparation method of anti-adhesion polyolefin cable material, comprises the following steps:

[0021] S1. Mix 70~100 parts of ethylene-octene copolymer, 10~20 parts of ethylene-vinyl acetate copolymer, 5~20 parts of FX-5924, 3~5 parts of silicone, 1~3 parts of glyceryl palmitoyl stearate Parts, 0.5~2 parts of nano-magnesium silicate, 0.5~2 parts of antioxidant, 0.1~1 part of light stabilizer are added to the internal mixer to mix and plasticize, and then conveyed into the screw extruder through double-cone shearing for extrusion, water Strand granulation to obtain material B;

[0022] S2. 36~50 parts of ethylene-octene copolymer, 8~10 parts of ethylene-vinyl acetate copolymer, 15~20 parts of maleic anhydride grafted ethylene-octene copolymer, 5~20 parts of maleic anhydride grafted polyethylene 10 parts, 25~35 parts of aluminum hydroxide, 15~25 parts of magnesium hydroxide, 2~5 parts of sodium isethionate, 1.5~3 parts of trimethylolpropane tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com