Production method of composite material by multilayer diagonal winding and production line

A composite material layer and composite material technology, which is applied in the field of multi-layer cable-stayed winding production of composite materials and its production line, can solve the problems of low torsional strength, easy cracking of axial fibers, and limited application range, so as to reduce production Low cost, low overall cost, and shortened feeding distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

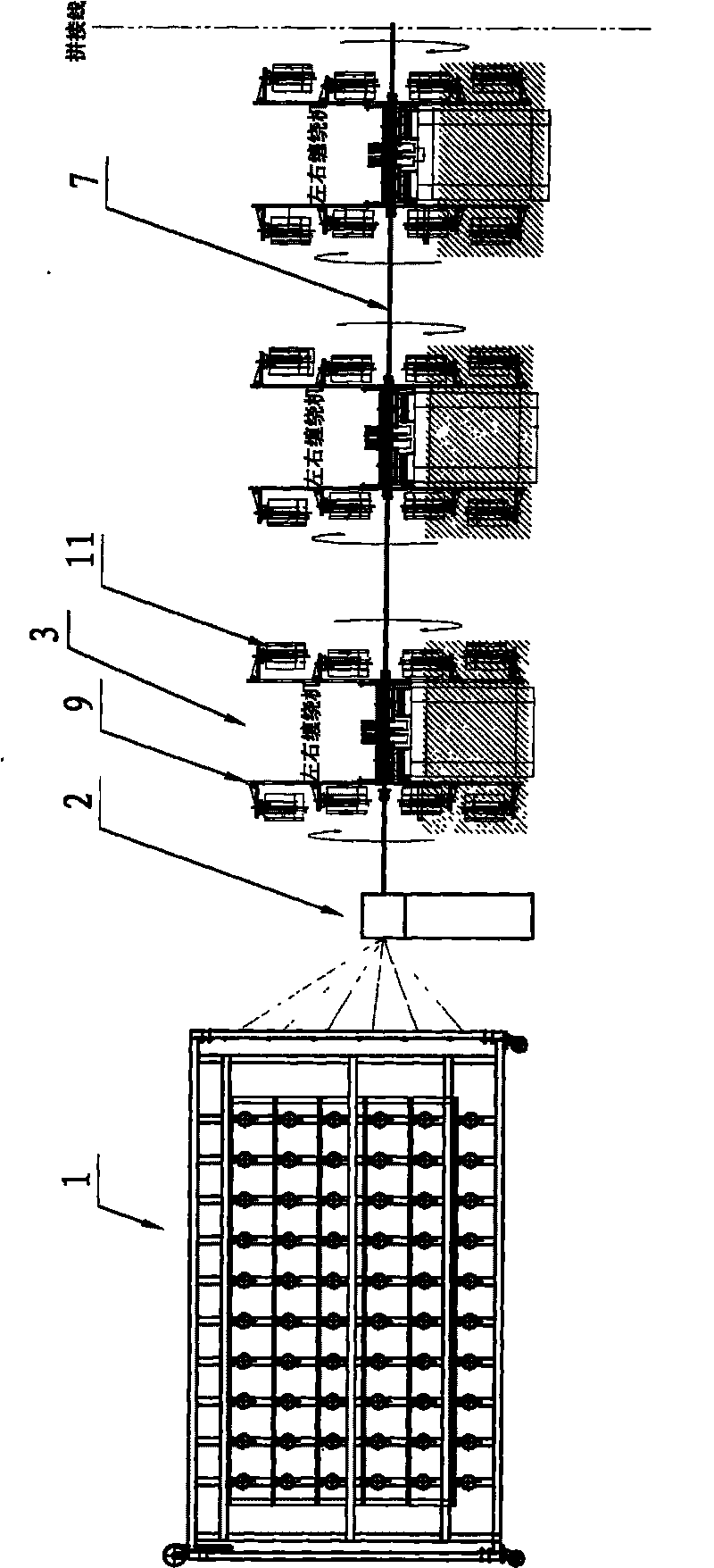

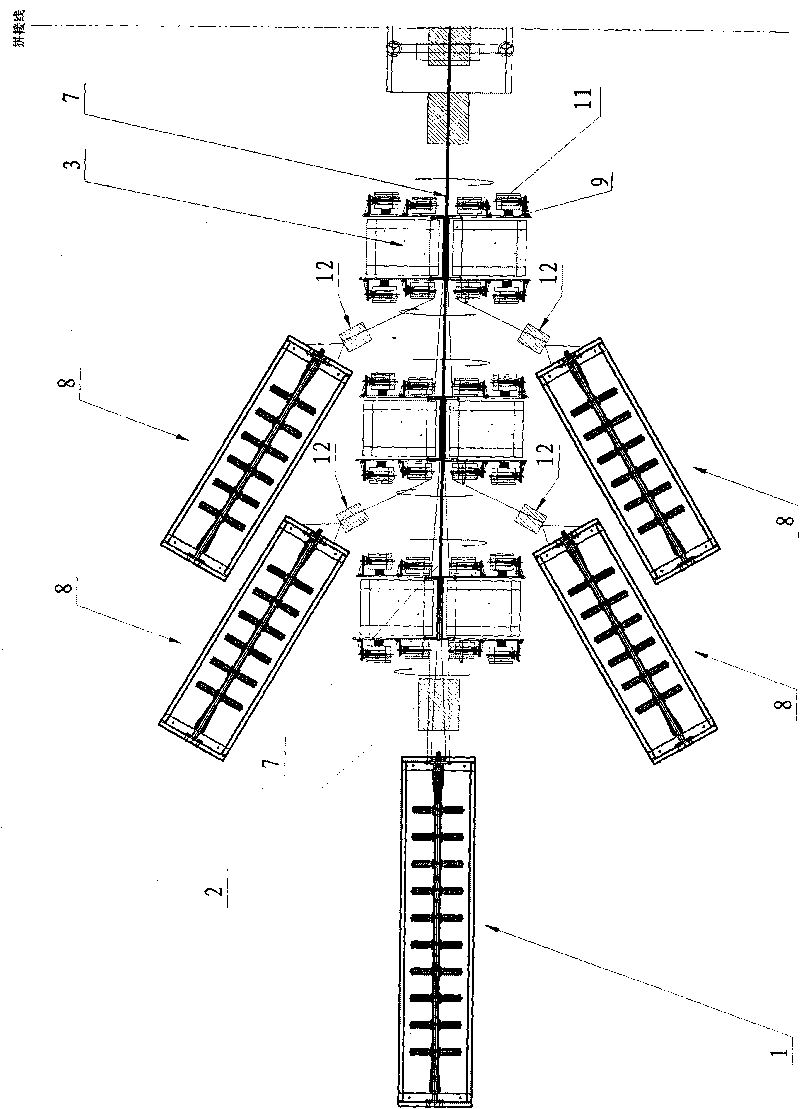

[0028] As shown in Figure 1 and 2.

[0029] A kind of multi-layer pultrusion winding production method of composite empty composite profile, it comprises the following steps:

[0030] Firstly, the multi-strand composite material fiber (such as carbon fiber, glass fiber, etc.) is drawn out from the axial constant tension wire rack 1 by a tractor at a uniform speed, and the multi-strand tow is impregnated along the mandrel through the axial dipping tank 2. 7 (can be a circular, elliptical or polygonal structure) arranged in parallel in the axial direction to form an uncured first layer of axial composite material layer consistent with the shape of the mandrel 7;

[0031] Make the above-mentioned first layer of axial composite material tow that is consistent with the shape of mandrel 7 pass through the axial dipping tank, and impregnate the adhesive (can be determined according to the type of composite material tow used, which can be epoxy Resin and (vinyl resin) are driven forw...

Embodiment 2

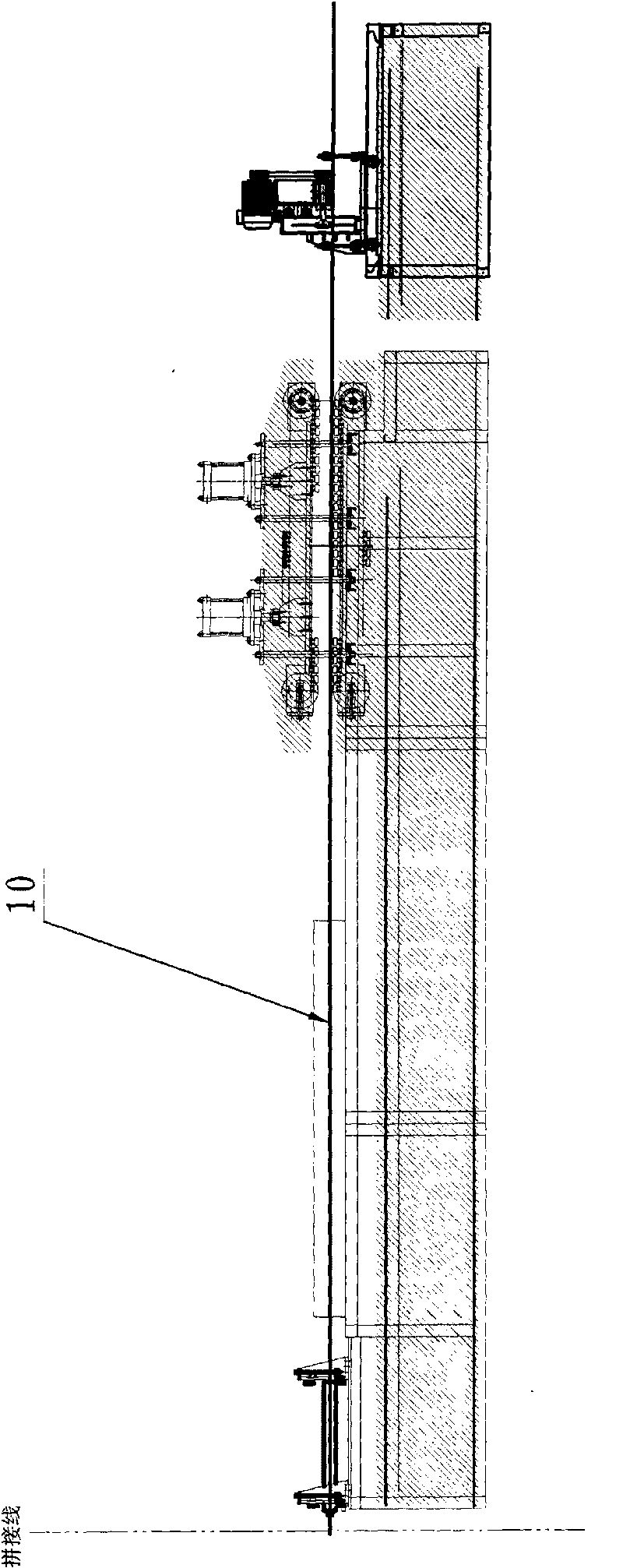

[0037] As shown in Figure 1 and 2.

[0038]A multi-layer pultrusion and winding production line for empty composite profiles of composite materials, which includes an axial tension wire rack 1, an axial dipping tank 2, a mold heating device 4, a tractor 5 and a cutting machine 6, and the axial constant tension The wire rack 1, the axial dipping tank 2, the mold heating device 4, the post-curing box 10 tractor 5 and the cutting machine 6 are all installed on the frame, and the axial dipping tank 2 and the oblique dipping tank 12 are preferably equipped with Heating the dipping tank of the constant temperature device to ensure that the binder will not thicken, prolong the use time, and facilitate the fiber to have good pultrusion permeability. It is best to have a corresponding glue volume control mechanism at the exit of the dipping tank. Squeeze excess binder on the tow back into the dipping tank and control the glue content. Between the outlet end of the axial dipping tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com