Long-acting formaldehyde-free impregnated paper and its preparation method

An impregnated paper, long-lasting technology, applied in the direction of papermaking, paper, textiles and papermaking, etc., can solve the problems that cannot be completely removed, the bond strength of the resin system is reduced, and the wet strength of the impregnated paper is reduced, so as to improve the impregnated bonding performance and Effects of storage characteristics, improvement of transparency and quantification, and guarantee of environmental characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

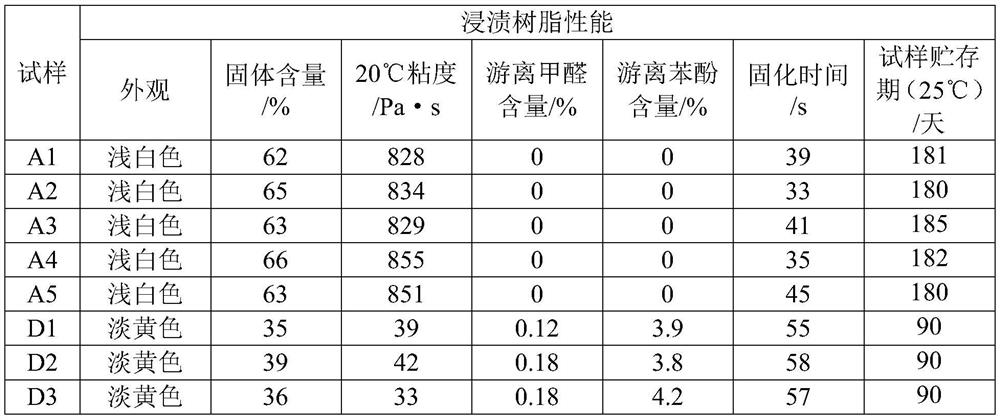

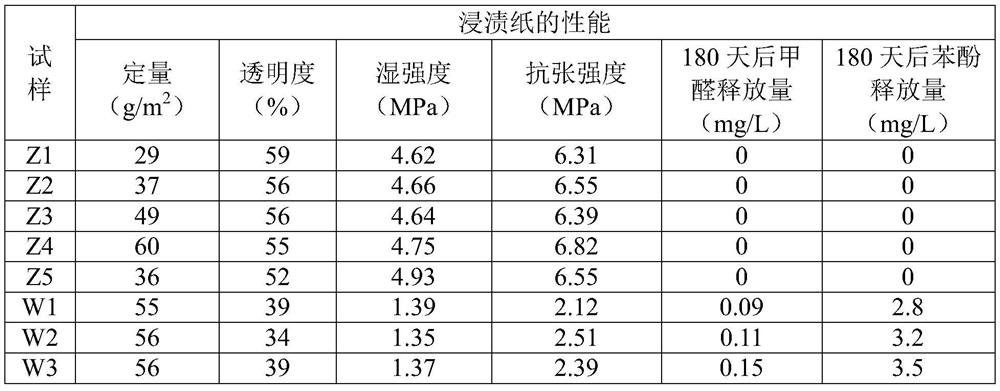

[0032] Example 1: Preparation of long-acting formaldehyde-free impregnated paper

[0033] 1. Reinforcement phase preparation

[0034] 1) Preparation of aldehyde-removing enhanced phase matrix: Add 100 parts by weight of nano coconut fiber carbon to 212 parts by weight of absolute ethanol to form a mixed solution. The average particle size of coconut fiber carbon is 80nm, and its micropore volume is not less than 92%. The average pore diameter of the pores is 5nm, ultrasonic treatment for 20min, and drying at 80°C for 30min to obtain a nano-solid; add 331 parts by weight of anhydrous acetic acid to 100 parts by weight of nano-coconut carbon solids, and add 353 parts by weight of Ammonia solution with a mass fraction of 39% was used to obtain a mixed solution, which was dried at 95°C for 35 minutes to obtain an aldehyde-removing enhanced phase matrix powder;

[0035] 2) Surface deposition of aldehyde-removing enhancement phase matrix: adopt 180 parts by weight of 0.2 mol / L hydr...

Embodiment 2

[0049] Embodiment 2: Preparation of long-acting formaldehyde-free impregnated paper

[0050] 1. Reinforced phase preparation

[0051] 1) Preparation of aldehyde-removing enhanced phase matrix: Add 100 parts by weight of nano coconut fiber carbon to 212 parts by weight of absolute ethanol to form a mixed solution. The average particle size of coconut fiber carbon is 90nm, and its micropore volume is not less than 92%. The average pore diameter of the pores is 5nm, ultrasonic treatment for 20min, and drying at 80°C for 30min to obtain a nano-solid; add 331 parts by weight of anhydrous acetic acid to 100 parts by weight of nano-coconut carbon solids, and add 353 parts by weight of Ammonia solution with a mass fraction of 39% was used to obtain a mixed solution, which was dried at 95°C for 35 minutes to obtain an aldehyde-removing enhanced phase matrix powder;

[0052] 2) Surface deposition of aldehyde-removing enhancement phase matrix: adopt 180 parts by weight of 0.2mol / L hydro...

Embodiment 3

[0066] Embodiment 3: Preparation of long-acting formaldehyde-free impregnated paper

[0067] 1. Reinforced phase preparation

[0068] 1) Preparation of aldehyde-removing enhanced phase matrix: Add 100 parts by weight of nano coconut fiber carbon to 212 parts by weight of absolute ethanol to form a mixed solution. The average particle size of coconut fiber carbon is 105nm, and its micropore volume is not less than 92%. The average pore diameter of the pores is 5nm, ultrasonic treatment for 20min, and drying at 80°C for 30min to obtain a nano-solid; add 331 parts by weight of anhydrous acetic acid to 100 parts by weight of nano-coconut carbon solids, and add 353 parts by weight of Ammonia solution with a mass fraction of 39% was used to obtain a mixed solution, which was dried at 95°C for 35 minutes to obtain an aldehyde-removing enhanced phase matrix powder;

[0069] 2) Surface deposition of aldehyde-removing enhancement phase matrix: adopt 180 parts by weight of 0.2mol / L hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com