Biodegradable two-way stretching composite film and preparation method and application thereof

A biodegradable, biaxial stretching technology, applied in applications, biological packaging, other household appliances, etc., can solve problems such as the impact of material biodegradation performance, and achieve the effect of ensuring environmental protection characteristics, high haze, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing a biodegradable biaxially stretched composite film, comprising the following steps:

[0050] Coextrusion obtains unstretched raw material film, and described raw material film comprises at least one first resin layer A, and described first resin layer A comprises following component:

[0051] Polylactic acid, biodegradable elastomer and functional masterbatch;

[0052] The biodegradable elastomer is selected from polybutylene adipate / terephthalate, polybutylene succinate, polybutylene adipate / succinate, carbon dioxide copolymer, polycaprolactone at least one of;

[0053] The raw film is biaxially stretched.

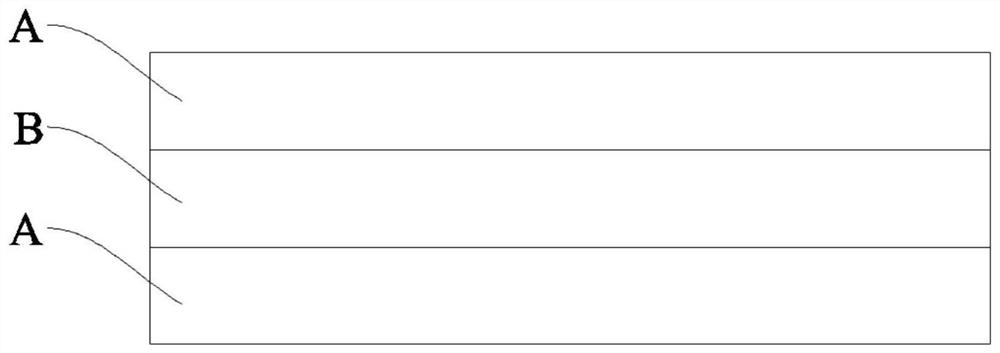

[0054] In some examples, seefigure 1 as shown, figure 1 Schematic diagram of the structure of some embodiments provided by the present invention, the biodegradable biaxially stretched composite film includes a three-layer structure, from top to bottom are the first resin layer A, the second resin layer B and the firs...

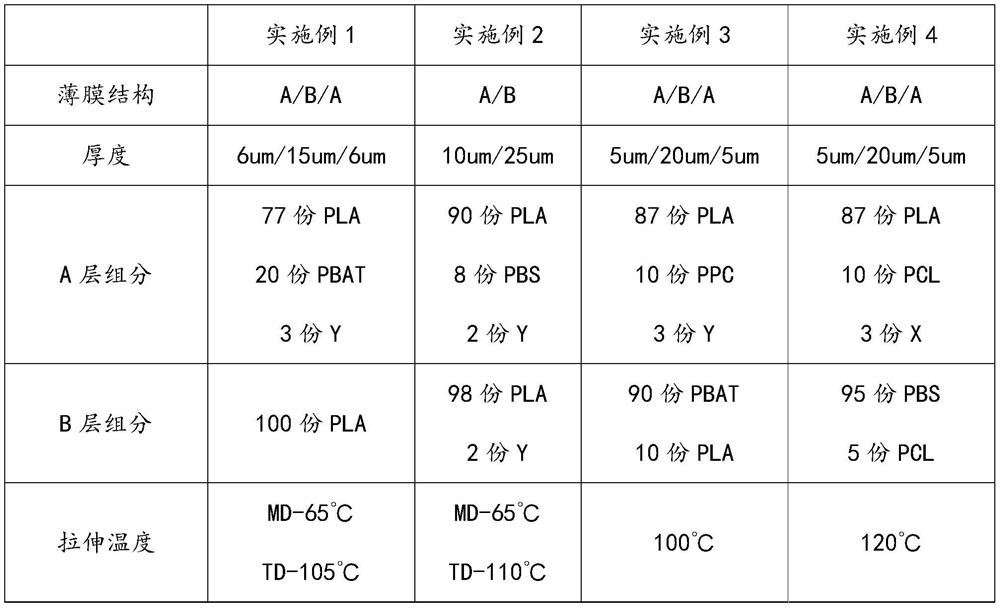

Embodiment 1

[0080] (1) Preparation of functional masterbatch Y:

[0081] In parts by weight, after mixing 3 parts of erucamide, 5 parts of silicon dioxide, 1 part of ethoxylated amine, 80 parts of polylactic acid and 11 parts of polybutylene succinate, the mixture is extruded by twin-screw The machine is extruded and granulated at 160-165°C for standby;

[0082] (2) Preparation of biodegradable biaxially oriented composite film:

[0083] refer to figure 1 , is a structural schematic diagram of a biodegradable biaxially stretched composite film disclosed in Example 1 of the present invention, including a three-layer structure arranged in sequence, wherein the first resin layer A, the second resin layer A, and the second resin layer are sequentially arranged from top to bottom. layer B and the first resin layer A;

[0084] In parts by weight, the components of the first resin layer A are 77 parts of polylactic acid, 20 parts of polyadipate / butylene terephthalate (PBAT), and 3 parts of fu...

Embodiment 2

[0095] (1) Preparation of functional masterbatch Y:

[0096] In parts by weight, after mixing 3 parts of erucamide, 5 parts of silicon dioxide, 1 part of ethoxylated amine, 80 parts of polylactic acid and 11 parts of polybutylene succinate, the mixture is extruded by twin-screw The machine is extruded and granulated at 160-165°C for standby;

[0097] (2) Preparation of biodegradable biaxially oriented composite film:

[0098] refer to figure 2 , is a structural schematic diagram of a biodegradable biaxially stretched composite film disclosed in Example 2 of the present invention, including a two-layer structure arranged in sequence, wherein the first resin layer A, the second resin layer A, and the second resin layer are sequentially arranged from top to bottom. Layer B;

[0099] In parts by weight, the components of the first resin layer A are 90 parts of polylactic acid, 8 parts of polybutylene succinate (PBS), and 2 parts of functional masterbatch Y;

[0100] In parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com