Adhesive for halogen-free high-Tg and low-dielectric type copper-clad plate, and preparation method thereof

A copper-clad laminate and adhesive technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the difficulties in production and processing of polyphenylene ether systems, high product costs, etc. problems, to achieve the effect of improving dielectric properties and reliability, low water absorption, and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the adhesive of the halogen-free high Tg low dielectric copper clad laminate adopts the following steps:

[0045] (1) prepare materials according to the composition of raw materials;

[0046] (2) Add organic solvent, biphenyl phenol type modified epoxy resin, and phosphazene flame retardant, control the speed at 1000-1500 rpm, keep warm at 30-50°C, and stir for 30-180 minutes;

[0047] (3) Add isocyanate-modified epoxy resin, modified polymeric anhydride, and active ester curing agent in sequence, at a speed of 1000-1500 rpm, keep warm at 30-50°C, and continue stirring for 30-120 minutes after adding;

[0048] (4) Add silane, inorganic filler and toughening agent sequentially according to the formula quantity, stir at a speed of 1000-1500 rpm for 90-180 minutes, and keep warm at 30-50°C;

[0049] (5) Add metal-type catalysts and imidazole catalysts in sequence according to the formula amount, stir at a speed of 1000-1500 rpm for 90-180 minutes...

Embodiment 1

[0053] 1. Prepare materials according to the formula composition

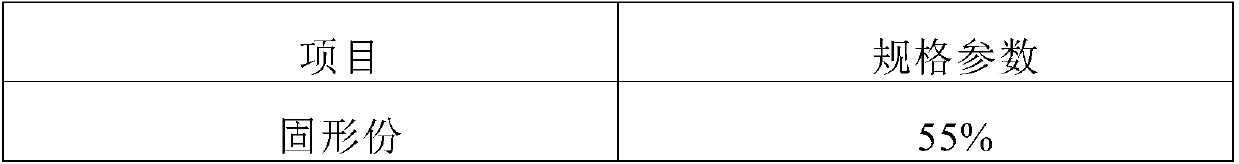

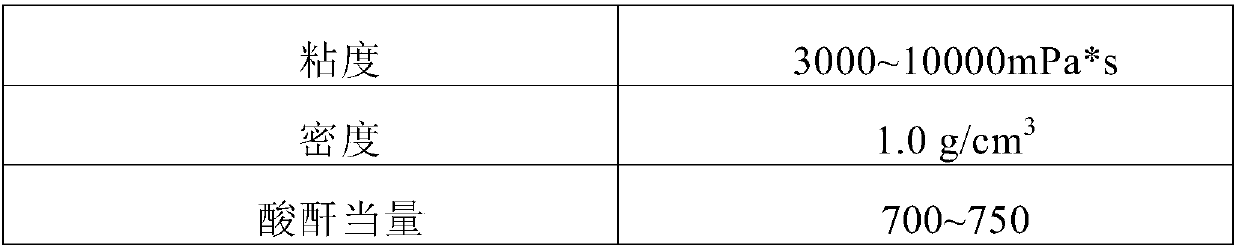

[0054] material name

Example 1

Phosphazene flame retardant (%)

16.7

Isocyanate Modified Epoxy Resin

12.6

Modified polymeric anhydride

24.6

Active ester curing agent

10.5

Biphenyl phenol type modified epoxy resin

18.5

metal catalyst

0.005

2-Ethyl-4 methylimidazole

0.01

Spherical silica (%)

21.8

Silane (%)

0.11

Organic solvents(%)

20.6

Toughener (%)

3.58

[0055] 2. Glue adjustment

[0056] 2.1 Add organic solvent, biphenyl phenol-type modified epoxy resin, and phosphazene flame retardant sequentially into the stirring tank according to the formula quantity, rotate at 1200 rpm, keep the tank at 30-50°C, and stir for 60 minutes;

[0057] 2.2 Add isocyanate-modified epoxy resin, modified polymeric anhydride, and active ester curing agent in sequence in the tank at a speed of 1300 rpm, and ...

Embodiment 2

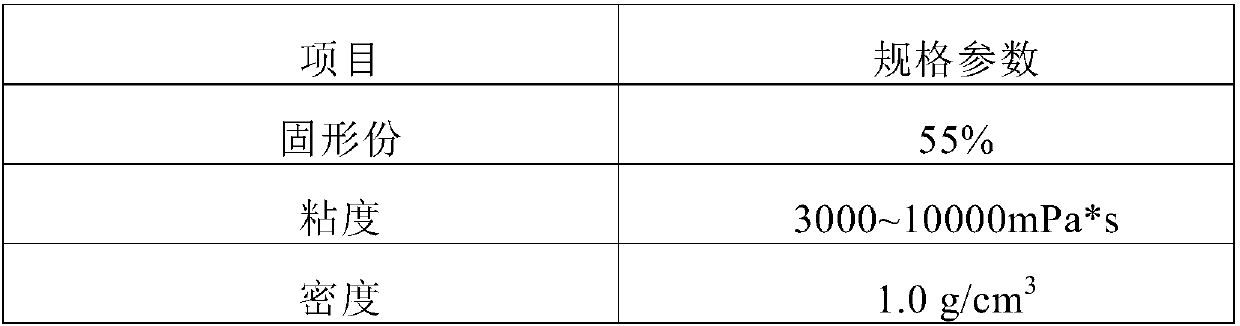

[0065] 1. Prepare materials according to the formula composition

[0066] material name

Example 2

Phosphazene flame retardant (%)

15.36

Isocyanate Modified Epoxy Resin

13.4

Modified polymeric anhydride

22.5

Active ester curing agent

11.5

Biphenyl phenol type modified epoxy resin

20.6

0.005

2-Ethyl-4 methylimidazole

0.01

Spherical silica (%)

24.5

Silane (%)

0.12

Organic solvents(%)

21.6

Toughener (%)

3.51

[0067] 2. Glue adjustment

[0068] 2.1 Add organic solvent, biphenyl phenol type modified epoxy resin, phosphazene flame retardant sequentially into the stirring tank according to the formula quantity, rotate at 1100 rpm, keep the tank at 30-50°C, and stir for 110 minutes;

[0069] 2.2 Add isocyanate-modified epoxy resin, modified polymeric anhydride, and active ester curing agent in sequence in the tank at a speed of 1100 rpm, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com