A strain of Lactobacillus plantarum, soybean milk fermented and produced based on the strain, and production method thereof

A technology of Lactobacillus plantarum and soybean milk, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of poor viscosity and fluidity, long fermentation period of soybean milk, and light yogurt aroma, etc., to achieve strong aroma, The taste is delicate, sour and sweet, and the fermentation cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the present invention, the preparation method of the fermentation broth of the Lactobacillus plantarum strain V02 preferably includes the following steps: inoculate the Lactobacillus plantarum strain V02 into pure soybean milk according to the inoculation amount of 2% to 5%, and ferment it at 37°C to Coagulate but no whey is separated out to obtain the fermentation broth of Lactobacillus plantarum strain V02. The fermentation time is preferably 8h-12h, more preferably 9-11h, most preferably 10h. The pure soybean milk is composed of 10%-15% soybean powder, 2%-6% additive and 79%-88% pure water, mixed and sterilized at 115°C for 10 minutes for use. The number of live bacteria in the fermented liquid of the Lactobacillus plantarum strain V02 is preferably 4.0~7.0×10 8CFU / g, more preferably 6.0×10 8 CFU / g. The additive is a sweetener or xylitol. The sweetener includes one or more of white granulated sugar, sucrose, glucose and malt syrup. When adding sweeteners to p...

Embodiment 1

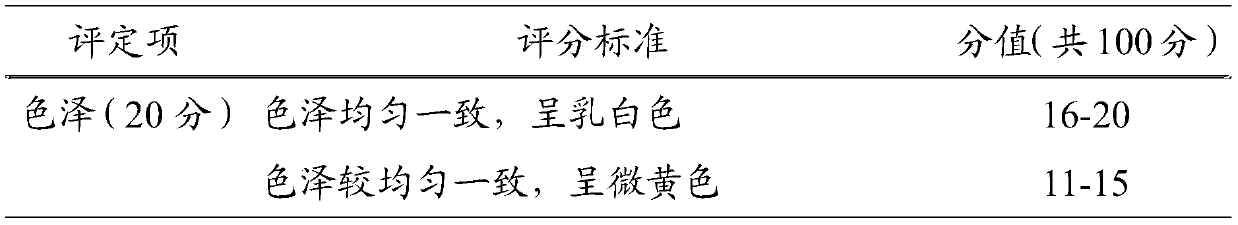

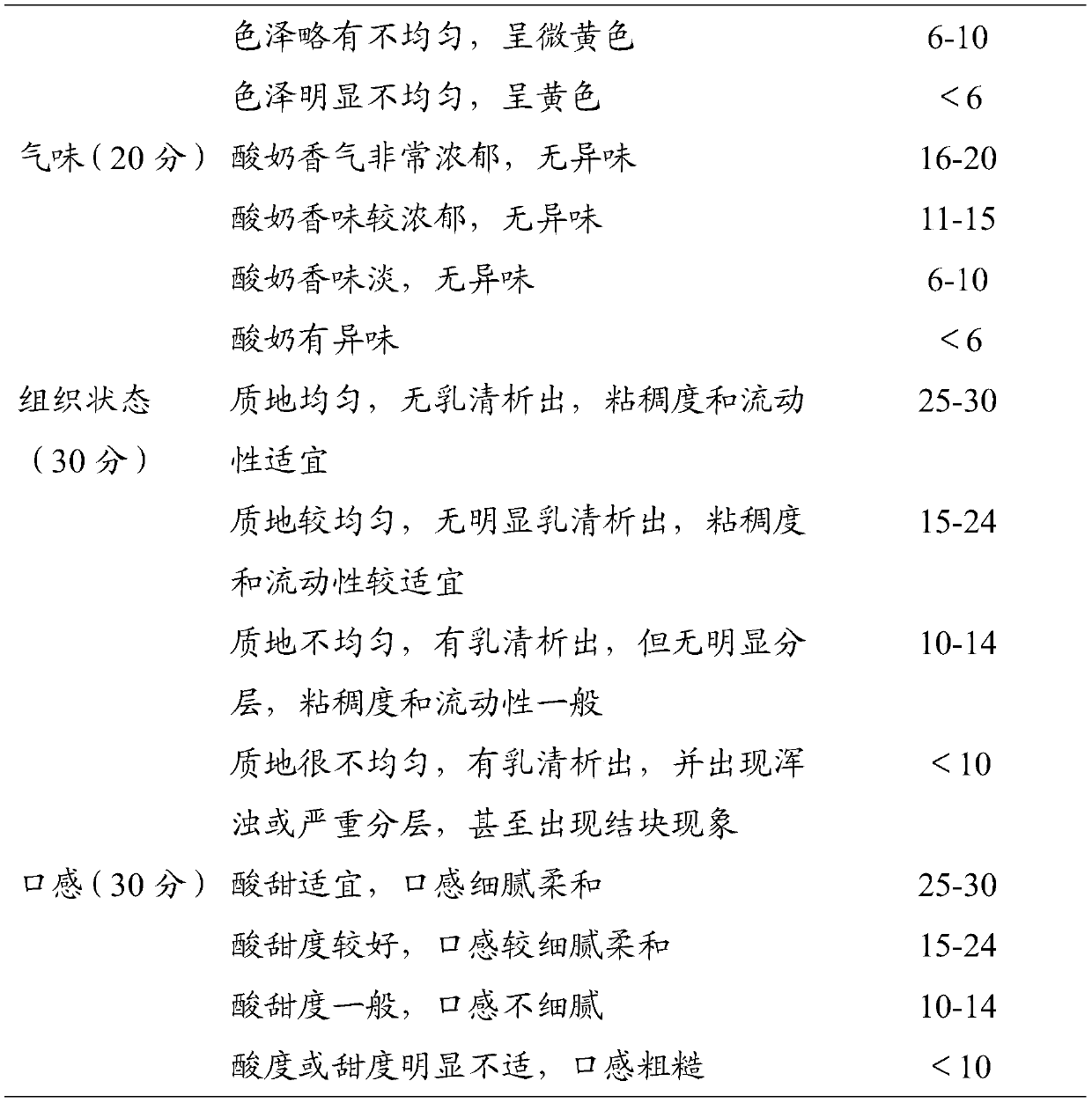

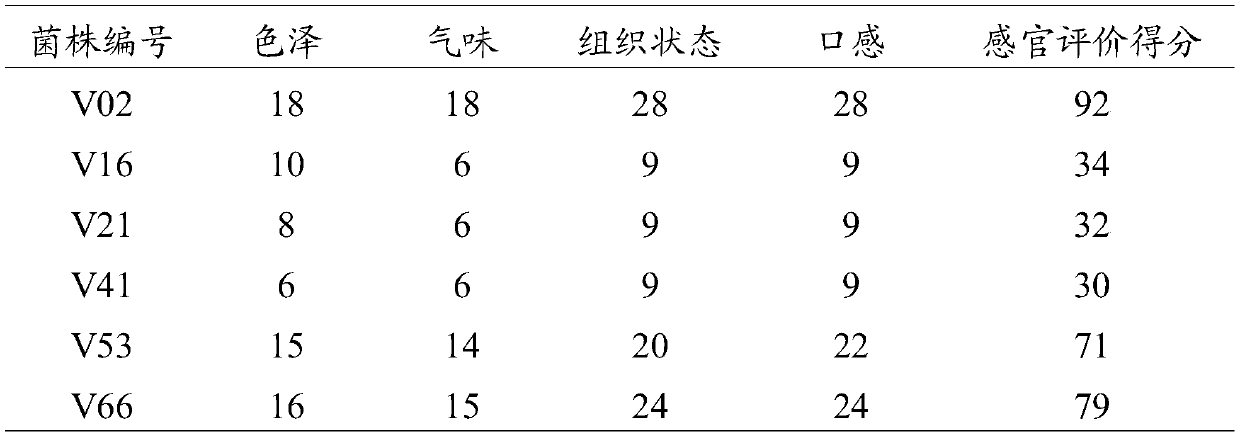

[0038] Screening method for Lactobacillus plantarum strains

[0039] (1) Six strains of Lactobacillus plantarum (respectively strains V02, V16, V21, V41, V53 and V66) derived from fermented vegetables were used in fermented soybean milk experiment, the specific method is as follows:

[0040] Plantarum Lactobacillus strain V02 was inoculated into pure soybean milk (by mass concentration 10% ~ 15% soybean powder, mass concentration 2% ~ 6 additives (xylitol or white granulated sugar) and mass concentration 79% according to the inoculation amount 2% ~ 5%. ~88% pure water, mixed and sterilized at 115°C for 10 minutes) and fermented at 37°C until coagulated but no whey was precipitated to obtain the fermentation broth of Lactobacillus plantarum strain V02. Add the fermented liquid of Lactobacillus plantarum strain V02 prepared by fermentation into sterilized soybean flour, and solidify the fermentation value at 37° C. to obtain sour soybean milk.

[0041] (2) Determination of coag...

Embodiment 2

[0050] Activation, expanded culture and fermented soybean milk of Lactobacillus plantarum V02 strain

[0051] (1) After transfer and activation of Lactobacillus plantarum V02 preserved in glycerol at -80°C, expand culture on sterilized MRS medium and ferment in a sterilized 100ml conical flask of pure soybean milk, the number of viable bacteria obtained is (4.0~7.0)× 10 8 CFU / g, fermented milk with a pH value of 4.0-4.5.

[0052] (2) Detection of the number of live bacteria and pH value of Lactobacillus plantarum V02

[0053] Weigh 25g fermented milk and put it into 225mL sterilized physiological saline, process it with a slap-type homogenizer at a speed of 8000-10000r / min for 1min, shake it fully, and make 10 -1 The uniform dilution solution; then make 10-fold incremental dilution to 10 with 9mL sterile saline -8 ; take 10 -6 ~10 -8 Place 1mL of each dilution solution in a sterile plate, pour about 15mL of sterilized MRS medium that has been melted and cooled to 44°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com