Long-chain alkyl polyoxyethylene hydrophobically modified guar gum thickening agent and preparation method thereof

A long-chain alkyl polyoxyethylene based technology, long-chain alkyl polyoxyethylene technology, applied in the field of guar gum derivatives, can solve the problems of low reaction efficiency, precipitation, corrosive price, etc., and achieve product properties The effects of uniformity, mild reaction conditions, and increased contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

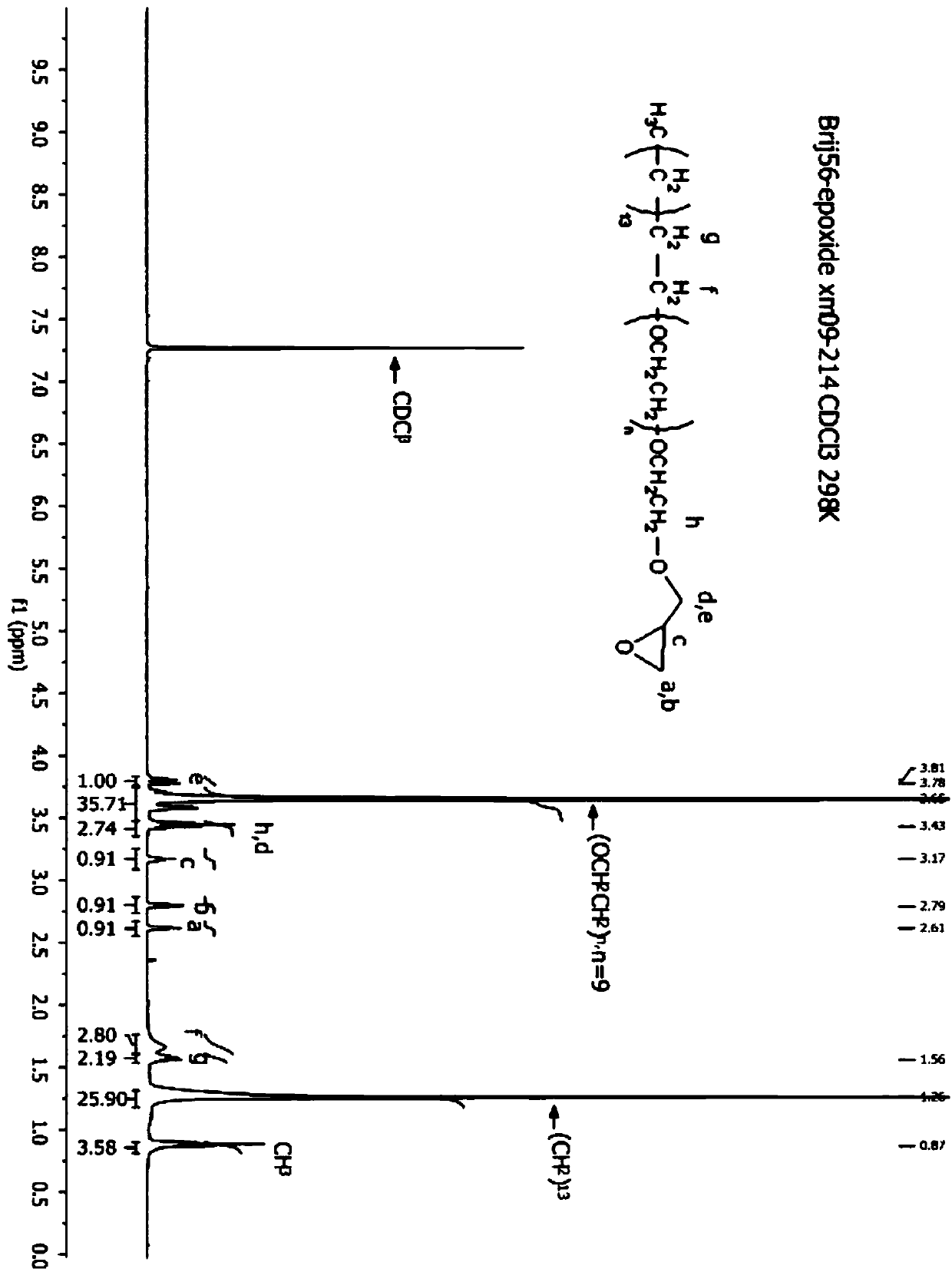

[0041] Dissolve 0.0089 mol (5.89 g) of polyoxyethylene (10) cetyl ether in anhydrous toluene, and remove water azeotropically. Under the protection of nitrogen, add 0.044mol (1.05g) sodium hydride to the flask, then add 58mL of anhydrous toluene, then re-dissolve the dehydrated Benzene in 30mL of anhydrous toluene, add to the flask, and stir for 1h. Then 0.0623mol (3.60g) of propylene oxide was added to the reactant, and reacted at 30°C for 5h. The mixture was placed in a refrigerator at 4°C overnight to separate the solid and liquid. The liquid was carefully separated and the toluene was distilled off under reduced pressure to obtain the product polyoxyethylene (20) cetyl ether glycidyl ether (code name Brij56-epoxide xm09-214), which was sample 1. The product was obtained without further purification in 95% yield. The product Brij56-epoxidexm09-214 was dissolved in deuterated chloroform (CDCl 3 ), and then carry out the proton nuclear magnetic resonance spectrum analysis,...

Embodiment 2

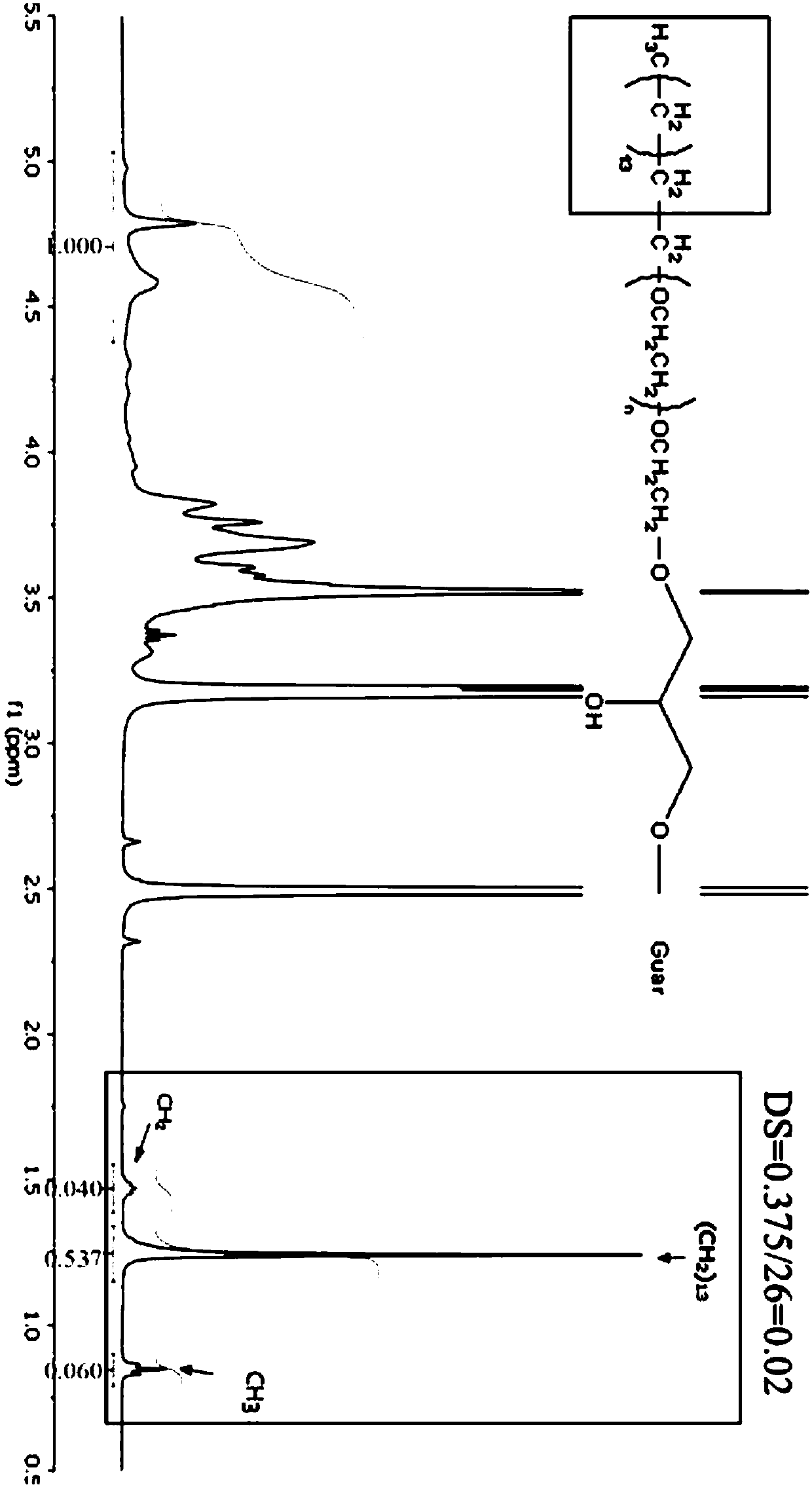

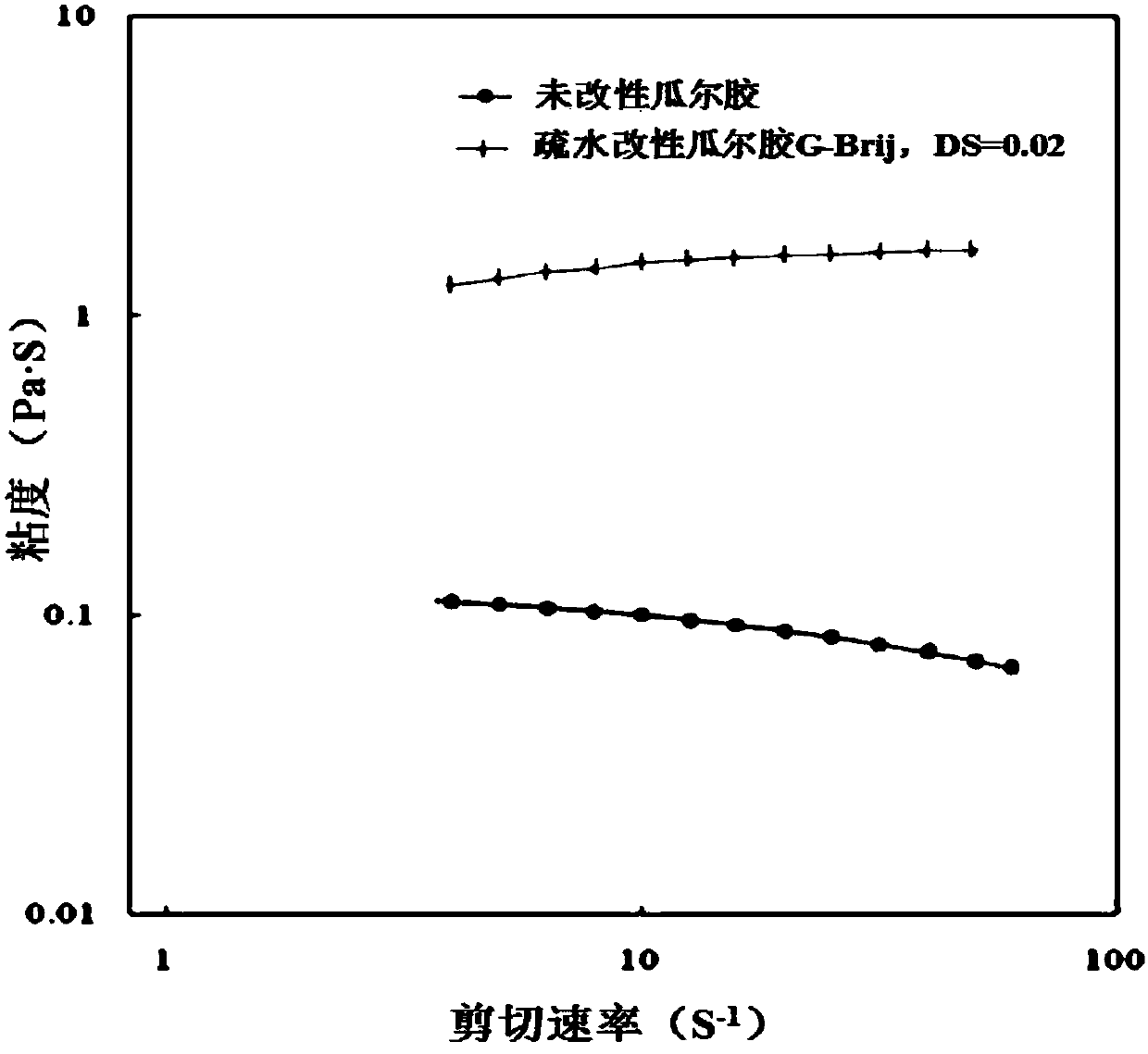

[0045] Dissolve 1 g of guar gum in 100 g of water and stir for 8 hours. Tetrabutylammonium hydroxide (TBAOH) was added, the molar ratio of TBAOH to guar unit was 5, stirred at room temperature for 1 hour, and the solution was freeze-dried. Put the freeze-dried solid into 100g of dimethyl sulfoxide (DMSO), stir at room temperature for 1 hour, then add long-chain alkyl polyoxyethylene glycidyl ether sample 1, long-chain alkyl polyoxyethylene The molar ratio of glycidyl ether to guar gum was 0.2. Stir at room temperature for 1 day. The above-mentioned reactant was diluted with 10g of water, then packed into a dialysis bag, and the dialysis bag was put into 1000g of water / ethanol (50:50v / v) mixture, stirred and dialyzed, and the water / ethanol (50:50v / v) was changed every 6 hours. v) The mixture was changed 2 times in total, and then dialyzed in 1000 g of water, changing the water every 6 hours, 2 times in total. The dialyzed solution was transferred from the dialysis bag to a r...

Embodiment 3

[0047] 1 g of guar gum was dissolved in 20 g of water and stirred for 24 hours. Add tetrabutylammonium hydroxide (TBAOH), the molar ratio of TBAOH to guar unit is 1, stir at room temperature for 1 hour, and freeze-dry the solution. Put the freeze-dried solid into 20 g of dimethyl sulfoxide (DMSO), stir at room temperature for 8 hours, then add long-chain alkyl polyoxyethylene glycidyl ether sample 1, long-chain alkyl polyoxyethylene The molar ratio of glycidyl ether to guar gum was 0.01, and stirred at room temperature for 8 days. The above-mentioned reactant was diluted with 100g of water, then packed into a dialysis bag, and the dialysis bag was put into 1000g of water / ethanol (50:50v / v) mixture, stirred and dialyzed, and the water / ethanol (50:50v / v) was changed every 3 hours. v) The mixture was changed 3 times in total, and then dialyzed in 1000 g of water, changing the water every 3 hours, 3 times in total. The dialyzed solution was transferred from the dialysis bag to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com