3D printing method, 3D printing light-curing color-changing indicating resin and preparation method thereof

A 3D printing and instruction technology, applied in the field of 3D printing, can solve the problems of decreased mechanical properties of materials, no secondary curing, multiple curing of materials, etc., to reduce volume shrinkage, improve mechanical properties, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

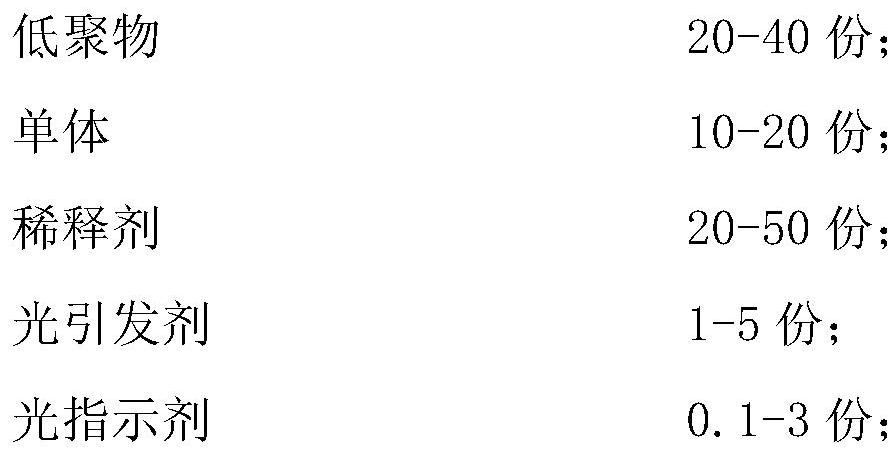

Method used

Image

Examples

Embodiment 1

[0039]25 parts of polyurethane acrylate, 20 parts of tricyclodecane dimethanol diacrylate, 40 parts of dipropylene glycol diacrylate, 0.5 parts of isopropylthioxanthone (2,4 isomer mixture), 1 part of 2, 4,6-trimethylbenzoyl-diphenylphosphine oxide, 1 part of N-hydroxyethyl-3,3-dimethyl-6-nitroindoline spiropyran, 0.5 part of polytetrafluoroethylene Nano powder, 0.2 part of 6-tert-butyl-2,4-dimethylphenol, 0.1 part of AFE-0030, 0.5 part of BYK-354 are mixed in the batching kettle, 60-70 ℃, 1000rpm / min stirring for 3 hours to obtain a solution , which is 3D printing photosensitive resin. After the prepared photosensitive resin is cured by ultraviolet light, its mechanical strength and volume shrinkage are evaluated. At the same time, the printed sample is subjected to secondary curing, and the mechanical strength and color of the sample after secondary curing are evaluated. In addition, the color of the sample was evaluated after the post-cured sample was placed in an environm...

Embodiment 2

[0045] 30 parts epoxy acrylate, 20 parts (10) ethoxylated bisphenol A diacrylate, 40 parts ethoxylated trimethylolpropane triacrylate, 1.5 parts isopropyl thioxanthone (2,4 isomer Body mixture), 1 part of 1-hydroxy-cyclohexyl-phenyl ketone, 1 part of N-methyl-N-nitrosoaniline, 1.5 parts of polytetrafluoroethylene nano powder, 0.2 parts of p-hydroxyanisole, Mix 0.1 part of ACP-3183 and 0.5 part of AKN-1158 in a batching kettle, stir at 60-70°C and 1000rpm / min for 3 hours to obtain a solution, which is the 3D printing photosensitive resin. After the prepared photosensitive resin is cured by ultraviolet light, its mechanical strength and volume shrinkage are evaluated. At the same time, the printed sample is subjected to secondary curing, and the mechanical strength and color of the sample after secondary curing are evaluated. In addition, the color of the sample was evaluated after the post-cured sample was placed in an environment without ultraviolet light and at room temperatu...

Embodiment 3

[0051] 30 parts of unsaturated polyester resin, 15 parts (4) ethoxylated bisphenol A diacrylate, 45 parts of triethylene glycol dimethacrylate, 2 parts of 819, 1 part of bromopropionyl spirobenzoxazine ring Mix hexane, 3 parts of polytetrafluoroethylene nanopowder, 0.2 part of hydroquinone, 0.1 part of ACP-0544, and 1.5 parts of MOK-2024 in a batching kettle, stir at 60-70 °C and 1000 rpm / min for 3 hours to obtain a solution, It is 3D printing photosensitive resin. After the prepared photosensitive resin is cured by ultraviolet light, its mechanical strength and volume shrinkage are evaluated. At the same time, the printed sample is subjected to secondary curing, and the mechanical strength and color of the sample after secondary curing are evaluated. In addition, the color of the sample was evaluated after the post-cured sample was placed in an environment without ultraviolet light and at room temperature for 24 hours. Each component consists of the following parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com