A kind of comprehensive utilization method of tributoxyethyl phosphate wastewater

A technology of tributoxyethyl phosphate and waste water, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, water pollutants, etc. and other problems, to achieve the effect of increasing the effective content, easy curing, and convenient packaging and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

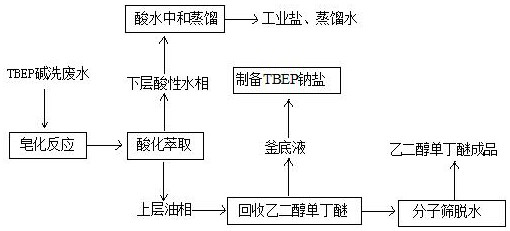

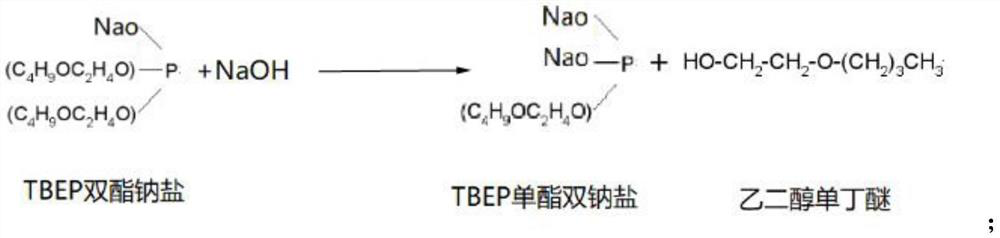

Method used

Image

Examples

Embodiment 1

[0048] Wastewater: Alkali washing wastewater produced by TBEP, after analysis: total phosphorus = 14058.7ppm, COD = 112965.3mg / L, pH = 9, sodium chloride 0.0347%, ethylene glycol monobutyl ether 4.85%, TBEP6.04%, TBEP double Ester sodium salt 9.2%, the appearance of the precipitate is a colorless transparent liquid after filtration.

[0049] A kind of treatment method of tributoxyethyl phosphate wastewater, the steps are as follows:

[0050] 1) Saponification reaction: Stir 330kg of TBEP alkaline washing waste water in a reactor and heat it up to 85°C, add 30% aqueous sodium hydroxide solution under stirring, and control the pH value of the wastewater in the reactor to remain at 8-9 (a total of 20% of hydrogen peroxide is added). Sodium aqueous solution 10.47kg), heat preservation reaction finishes saponification reaction after 3 hours, obtains saponification waste water;

[0051] 2) Acidification extraction: Step 1) Keep the temperature of saponification wastewater at 85°C, ...

Embodiment 2

[0057] Embodiment 2: a kind of treatment method of tributoxyethyl phosphate wastewater, method condition is the same as embodiment 1, but different from embodiment 1, the acidification pH value is controlled at 3-4 in step 2), finds saponification wastewater In an emulsified state that cannot be separated, it is considered that TBEP sodium salt has not reacted into TBEP hydroxyl compound.

Embodiment 3

[0058] Embodiment 3: a kind of treatment method of tributoxyethyl phosphate waste water, method condition is the same as embodiment 1, but different from embodiment 1, the acidification pH value is controlled below 1 in step 2), and sampling is measured lower layer acidity Aqueous phase COD=359.1mg / L, considering that there is an error in the detection, it can be considered that the result is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com