Preparation method of propyl trimethoxy silane

A technology of propyltrimethoxysilane and propyltrichlorosilane is applied in the field of preparation of propyltrimethoxysilane to achieve the effects of sufficient reaction, stable process and realization of DCS computer control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

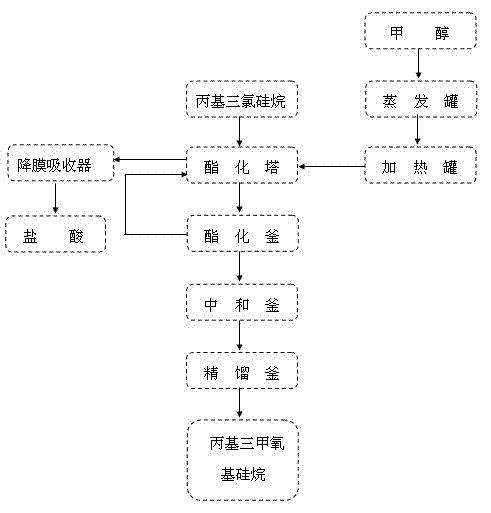

[0018] Such as figure 1 As shown, the steps include:

[0019] (1) Measure propyltrichlorosilane and methanol respectively through the flowmeter according to the mass ratio of 1.5:1. Methanol is vaporized in the evaporation tank, then passes through the heating tank, and then enters the bottom of the esterification tower. The top of the tower enters and sprays down, and the two react through countercurrent contact. The main product produced during the reaction falls to the bottom of the reactor, and the by-product HCl gas overflows from the gas overflow hole at the top of the esterification tower and passes through the falling film. The absorber absorbs and forms hydrochloric acid;

[0020] (2) Use a centrifugal pump to pump the main product at the bottom of the esterification tank to the top of the esterification tower, keep the top temperature of the esterification tower at 55°C, and while the main product is falling, the methanol gas flowing through the esterification to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com