Concrete anticorrosion material and preparation method thereof

A technology of anti-corrosion materials and concrete, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of coating fatigue aging, interface damage, peeling, etc., achieve good flexibility, improve durability, and improve acid and alkali resistance corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

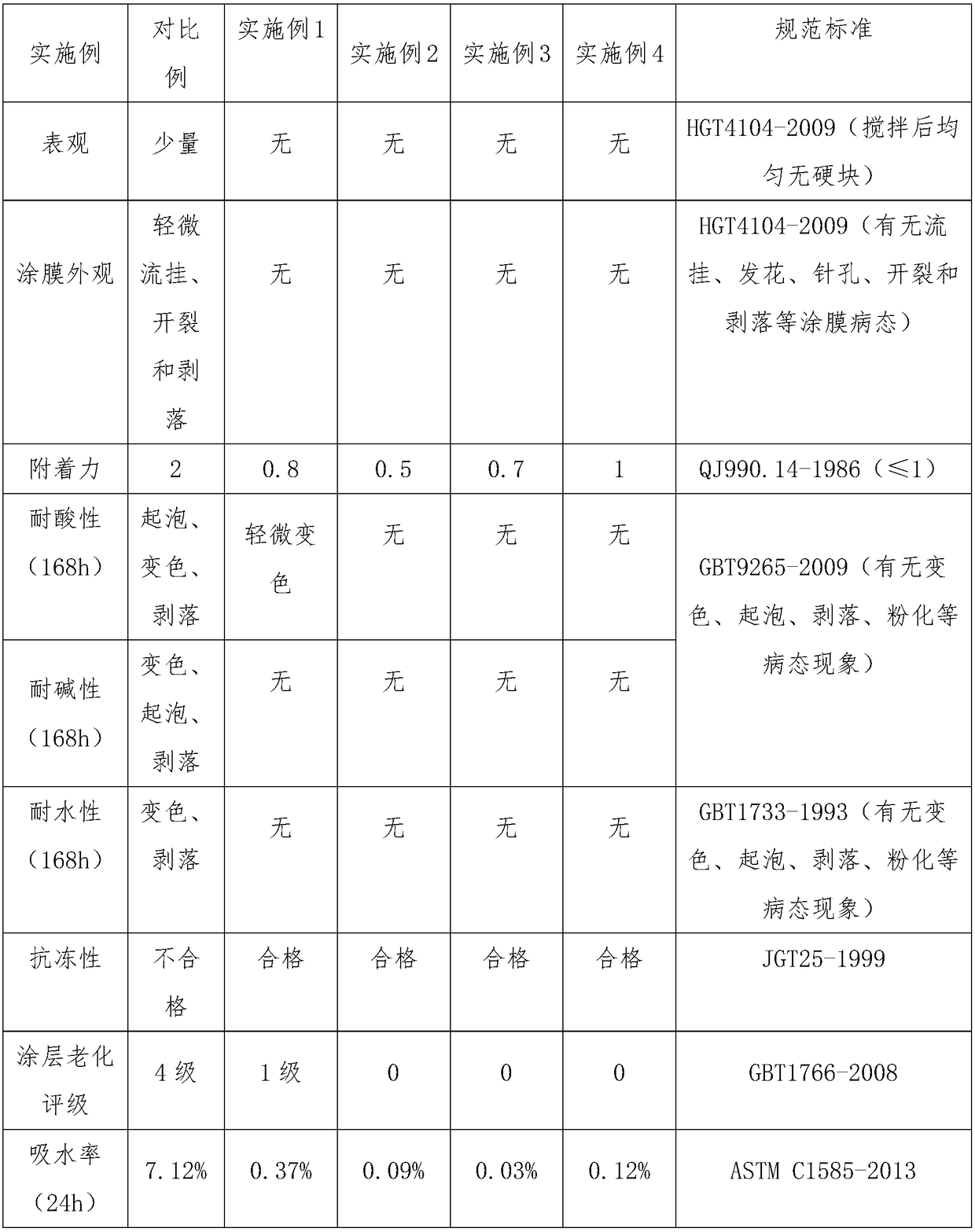

Examples

Embodiment 1

[0029] A composite modified concrete anticorrosion material given in this example is composed of the following raw materials in terms of weight percentage: 10% hydroxypropyl acrylate, 35.235% alkyd resin, 4% emulsifier, 0.04% graphene oxide, 3% hydrotalcite, 3% calcium hydroxide, 0.055% complexing agent, 0.07% carbon nanotube, 0.3% silicon nitride whisker, 3.5% coupling agent, 0.8% light stabilizer, 40% water.

[0030] The emulsifier is diacetyl tartaric acid mono-diglyceride, the coupling agent is borate coupling agent; the density of hydroxypropyl acrylate is 1.044g / mL, the refractive index is 1.445, and the solid content is ≥30%; the average alkyd resin The particle size is 16.75nm, the water absorption rate is 5.79%, the adhesion is grade 1, and the surface drying time is 1.5h~2h; the HLB value of the emulsifier is 7.0-9.0; graphene oxide is made from graphene through the Hummers oxidation method, and the diameter is 1~5μm. Monolayer ratio >99%, purity >99%, thickness 0.8-...

Embodiment 2

[0039] A composite modified concrete anticorrosion material given in this example is composed of the following raw materials in terms of weight percentage: 8% hydroxypropyl acrylate, 42% alkyd resin, 2% emulsifier, 0.02% graphene oxide, 3% hydrotalcite, 1% calcium hydroxide, 0.055% complexing agent, 0.07% carbon nanotube, 0.2% silicon nitride whisker, 2% coupling agent, 0.8% light stabilizer, 40.855% water.

[0040] Wherein the emulsifier is polyethylene glycol distearate, the coupling agent is an aluminate coupling agent, and the complexing agent consists of sodium ethylenediamine tetramethylene phosphate and mercaptoethylamine in a mass fraction of 66:34.

Embodiment 3

[0042] A composite modified concrete anticorrosion material given in this example consists of the following raw materials in terms of weight percentage: 9% hydroxypropyl acrylate, 37.015% alkyd resin, 3% emulsifier, 0.03% graphene oxide, Hydrotalcite 4%, calcium hydroxide 2%, complexing agent 0.065%, carbon nanotube 0.09%, silicon nitride whisker 0.25%, coupling agent 2.5%, light stabilizer 0.95%, water 41.1%; emulsifier is Sodium dodecylbenzenesulfonate, the coupling agent is silane coupling agent KH-570, and the complexing agent is composed of sodium ethylenediamine tetramethylene phosphate and mercaptoethylamine in mass fraction: 63:37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com