Setting accelerator for ceramic blanks

A technology of quick-setting agent and ceramic blank, which is applied in the field of ceramic manufacturing, can solve problems such as poor plasticity, and achieve the effects of good wear resistance, improved compatibility and accelerated coagulation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

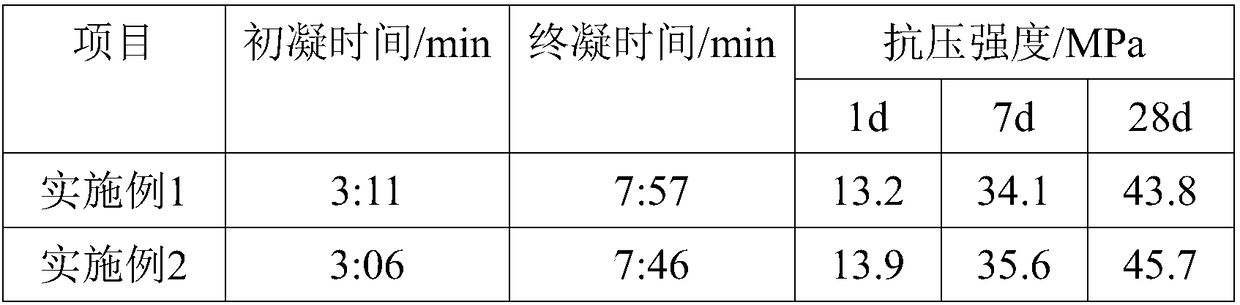

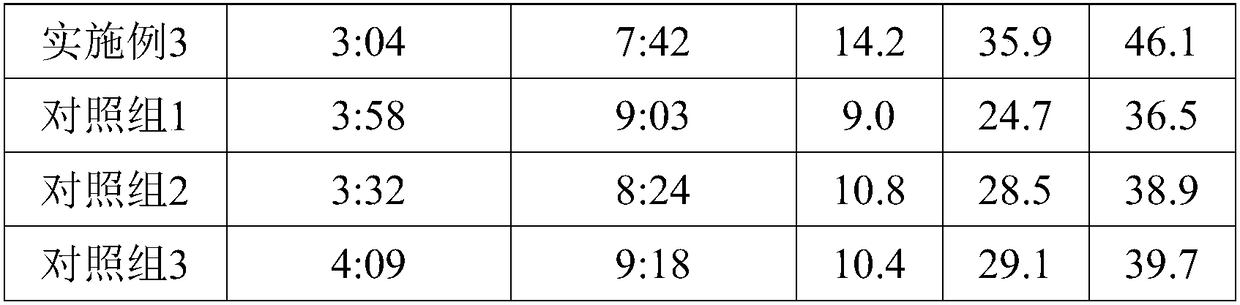

Examples

Embodiment 1

[0024] A quick-setting agent for ceramic blanks, characterized in that it is made of the following raw materials in parts by weight: 50 parts of asbestos powder, 20 parts of corn gluten, 10 parts of activated clay, 10 parts of paraffin, and 10 parts of sepiolite powder , 5 parts of sodium hydroxide, 5 parts of activated carbon powder, 10 parts of rice straw, 3 parts of alum, 3 parts of nano zinc oxide, 0.5 part of polyaspartic acid, and 0.5 part of citric acid.

[0025] The asbestos powder has been modified before use, and the treatment method is: add the asbestos powder to 2 times the weight of water, fully disperse it and let it stand for 30 minutes, then add disodium hydrogen phosphate and silane coupling agent, mix it uniformly and use plasma Surface treatment machine for 15s, after the treatment, quickly transfer to 5 ℃ environment and let it stand for 5 hours, then add squash gum, polyaluminum chloride, benzoin, mix well, and microwave at microwave frequency 2450MHz, powe...

Embodiment 2

[0036] A quick-setting agent for ceramic blanks, characterized in that it is preferably made of the following raw materials in parts by weight: 70 parts of asbestos powder, 25 parts of corn gluten, 15 parts of activated clay, 13 parts of paraffin, and 13 parts of sepiolite powder , 10 parts of sodium hydroxide, 8 parts of activated carbon powder, 13 parts of rice straw, 5 parts of alum, 5 parts of nano-zinc oxide, 0.8 part of polyaspartic acid, and 1.5 parts of citric acid.

[0037] The asbestos powder has been modified before use, and the treatment method is: add the asbestos powder to 2 times the weight of water, fully disperse it and let it stand for 30 minutes, then add disodium hydrogen phosphate and silane coupling agent, mix it uniformly and use plasma Surface treatment machine for 15s, after the treatment, quickly transfer to 10 ℃ environment and let it stand for 5 hours, then add squash gum, polyaluminum chloride, benzoin, mix well, and microwave at microwave frequency...

Embodiment 3

[0048] A quick-setting agent for ceramic blanks, characterized in that it is made of the following raw materials in parts by weight: 80 parts of asbestos powder, 30 parts of corn gluten, 20 parts of activated clay, 15 parts of paraffin, and 15 parts of sepiolite powder , 15 parts of sodium hydroxide, 10 parts of activated carbon powder, 15 parts of rice straw, 6 parts of alum, 6 parts of nano-zinc oxide, 1 part of polyaspartic acid, and 2 parts of citric acid.

[0049] The asbestos powder has been modified before use, and the treatment method is: add the asbestos powder to 2 times the weight of water, fully disperse it and let it stand for 30 minutes, then add disodium hydrogen phosphate and silane coupling agent, mix it uniformly and use plasma Surface treatment machine for 15s, after the treatment, quickly transfer to 10 ℃ environment and let it stand for 5 hours, then add squash gum, polyaluminum chloride, benzoin, mix well, and microwave at microwave frequency 2450MHz, powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com