Super-clean graphene and preparation method thereof

A graphene, ultra-clean technology, applied in the field of materials, can solve the problems of limited application, graphene light transmittance and conductivity decline, many defects, etc., and achieve the effect of simple and effective preparation method, efficient non-destructive transfer, and excellent structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

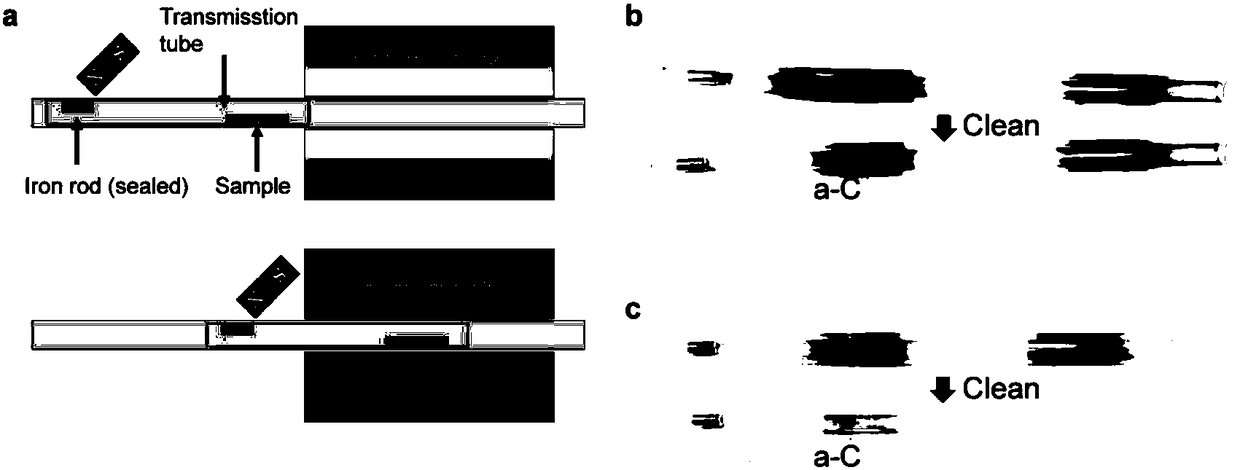

Method used

Image

Examples

Embodiment 1

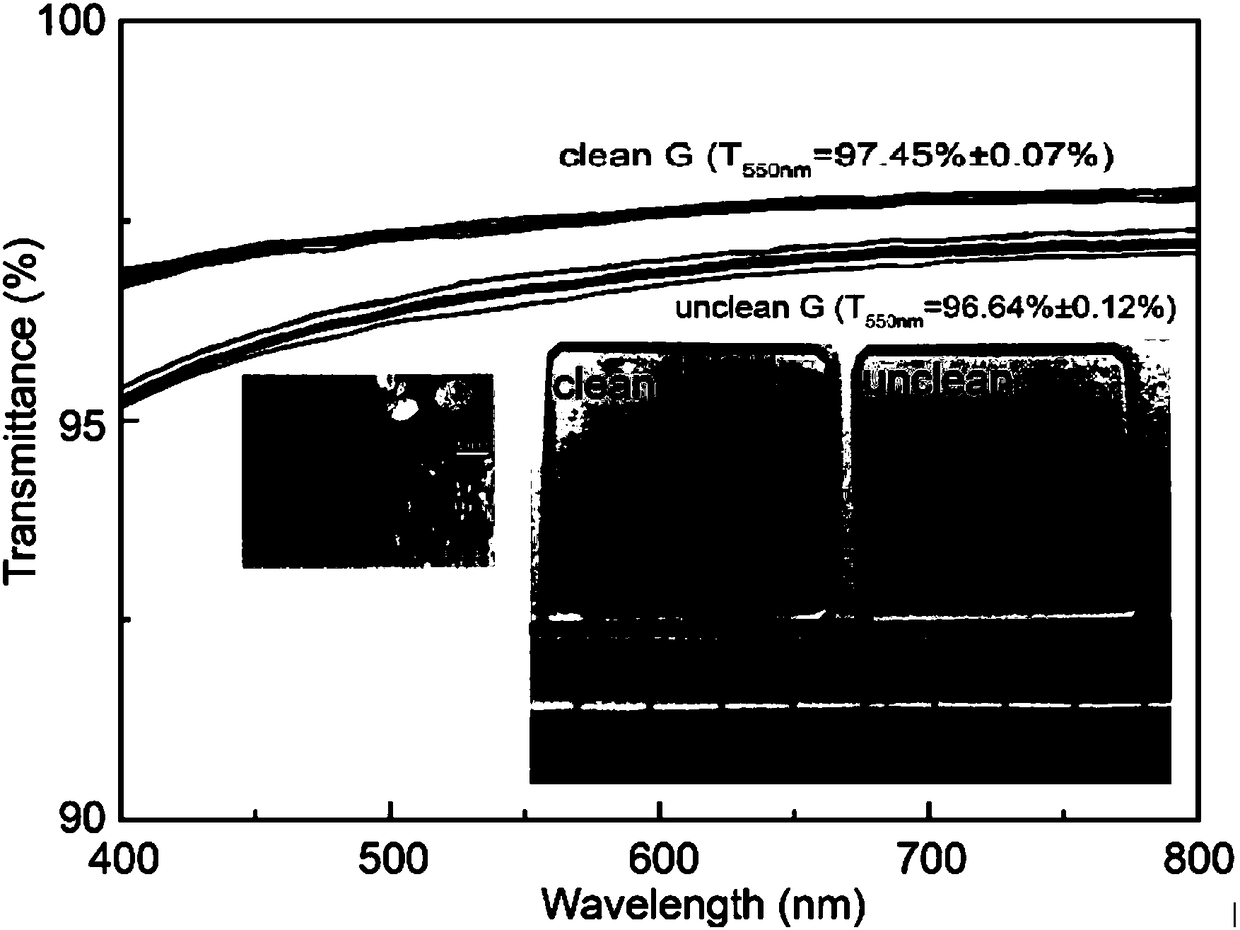

[0044] Embodiment 1, preparation ultra-clean graphene

[0045] (1) Use dilute hydrochloric acid and deionized water with a mass fraction of 5% to clean the copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm), and place the copper foil and foamed copper in close contact with a magnetic control device. Put the casing in the casing, and then place the casing in a tube furnace. Under a hydrogen atmosphere with a flow rate of 100sccm and a system pressure of 100Pa, raise the temperature of the furnace body to 1020°C and keep it for 30min;

[0046] (2) Keep the temperature of the furnace body at 1020° C., change the flow rate of hydrogen into hydrogen gas of 11 sccm, and feed in methane gas with a flow rate of 7 sccm. The system pressure is 50 Pa, and keep for 30 s;

[0047] (3) Use a magnet to drag the casing loaded with copper foil out of the high-temperature zone, and rapidly lower the temperature of the sample to room temperature at a cooling r...

Embodiment 2

[0053] Embodiment 2, preparation ultra-clean graphene

[0054] (1) Using phosphoric acid and ethylene glycol solution with a mass ratio of 3:1 as the electrolyte, copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) was connected to the positive electrode, and polished at a DC current of 0.5 A for 30 min. Place the copper foil and foamed copper in close contact with a casing with a magnetic control device, then place the casing in a tube furnace, and raise the temperature of the furnace body to 1040°C under a hydrogen atmosphere with a flow rate of 300 sccm, and the system The pressure is 300Pa, keep it for 50min;

[0055] (2) Keep the temperature of the furnace body at 1040° C., change the flow rate of hydrogen into 500 sccm of hydrogen gas, feed into methane gas with a flow rate of 0.36 sccm, and keep the system pressure at 500 Pa for 24 hours;

[0056] (3) Use a magnet to drag the sleeve loaded with copper foil out of the high temperature ...

Embodiment 3

[0062] Embodiment 3, preparation ultra-clean graphene

[0063] (1) Use dilute hydrochloric acid and deionized water with a mass fraction of 5% to clean the copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm), and place the copper foil and foamed copper in close contact with a magnetic control device. Put the casing in the casing, and then place the casing in a tube furnace. Under a hydrogen atmosphere with a flow rate of 100sccm and a system pressure of 100Pa, raise the temperature of the furnace body to 1020°C and keep it for 30min;

[0064] (2) Keep the temperature of the furnace body at 1020° C., change the flow rate of hydrogen into 11 sccm of hydrogen gas, and feed into methane gas with a flow rate of 1 sccm. The system pressure is 48 Pa, and keep for 300 s;

[0065] (3) Use a magnet to drag the casing loaded with copper foil out of the high-temperature zone, and rapidly lower the temperature of the sample to room temperature at a coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com