Preparation and application of ferroferric oxide composite metal chelate mimic enzyme

A technology of ferroferric oxide and composite metal, which is applied in the field of nanotechnology and analysis and detection, can solve the problems of complex analysis process, long analysis time and high analysis cost, and achieve the effect of simple separation process, good selectivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, Fe 3 o 4 -Cu 2+ Preparation of mimetic enzyme

[0038] Step 1, weigh 2.162gFeCl 3 ·6H 2 O, 5.4 g of sodium acetate trihydrate and 1.0 g of sodium lignosulfonate were dissolved in 70 mL of ethylene glycol, and the mixture was continuously stirred until completely dissolved;

[0039] Step 2. Transfer the solution obtained in step 1 to a high-pressure reactor equipped with a polytetrafluoroethylene liner, put it into an oven that has been heated to 200 ° C, react for 12 hours, and then cool to room temperature with the furnace;

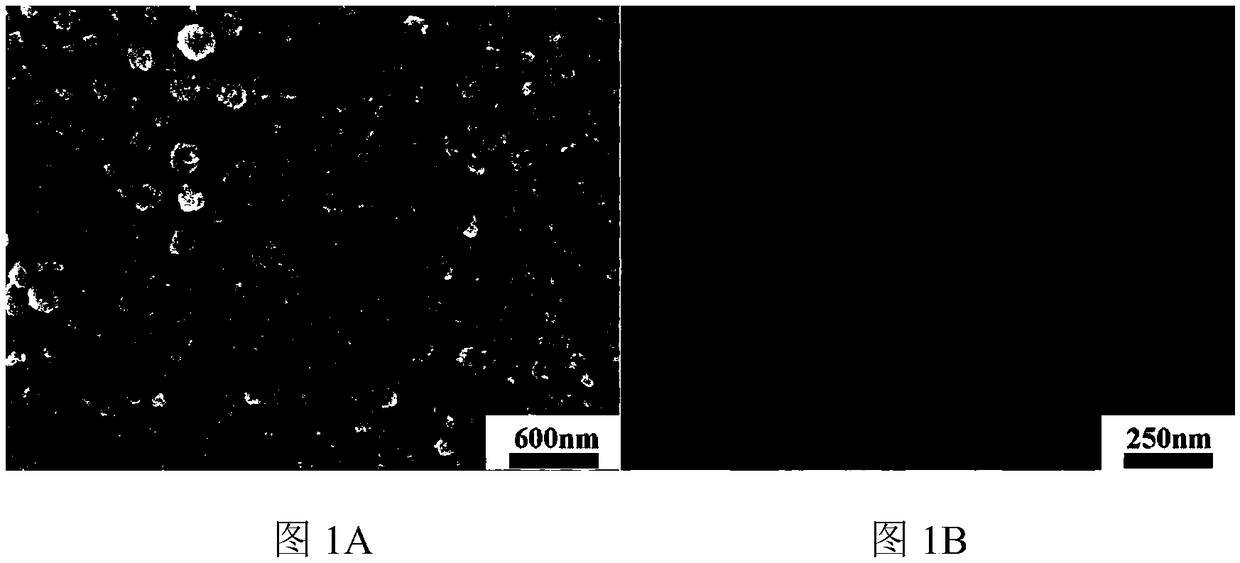

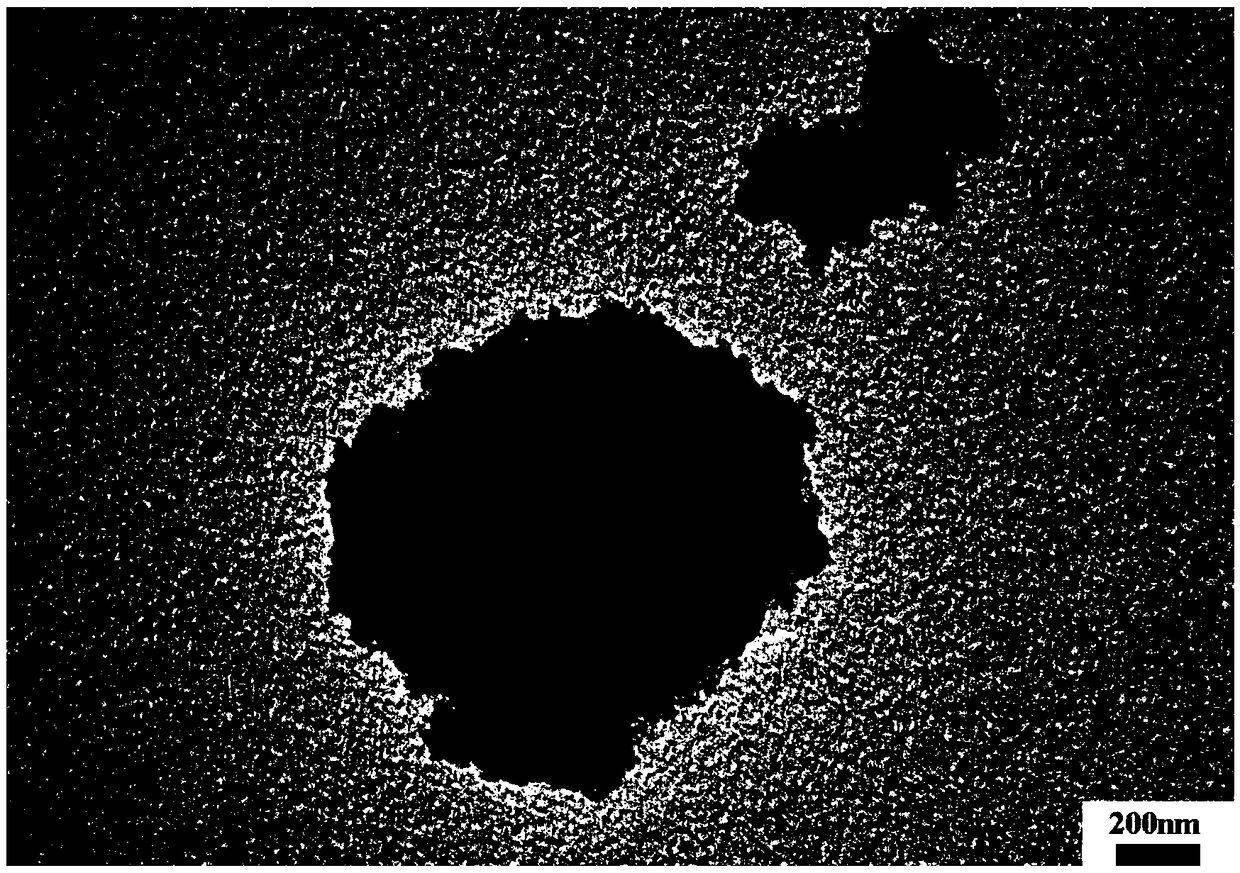

[0040] Step 3. Pour out the supernatant in the reaction kettle, take out the precipitate, wash with ethanol and deionized water at least three times, and dry at 60°C for 8 hours to obtain the sample Fe 3 o 4 -SL, using SEM to characterize it, it can be seen that it is a microsphere with a particle size of about 600nm, as shown in Figure 1 (A);

[0041] Step 4, under neutral environment, get the Fe that 0.02g step 3 obtains 3 o ...

Embodiment 2

[0044] Example 2, Fe 3 o 4 -Cu 2+ The detection steps of the simulated enzyme as a peroxidase to hydrogen peroxide are as follows:

[0045] Step (1), the Fe obtained in Example 1 3 o 4 -Cu 2+ The simulated enzyme is dispersed in water to produce 0.8mg / mL Fe 3 o 4 -Cu 2+ Simulated enzyme dispersion;

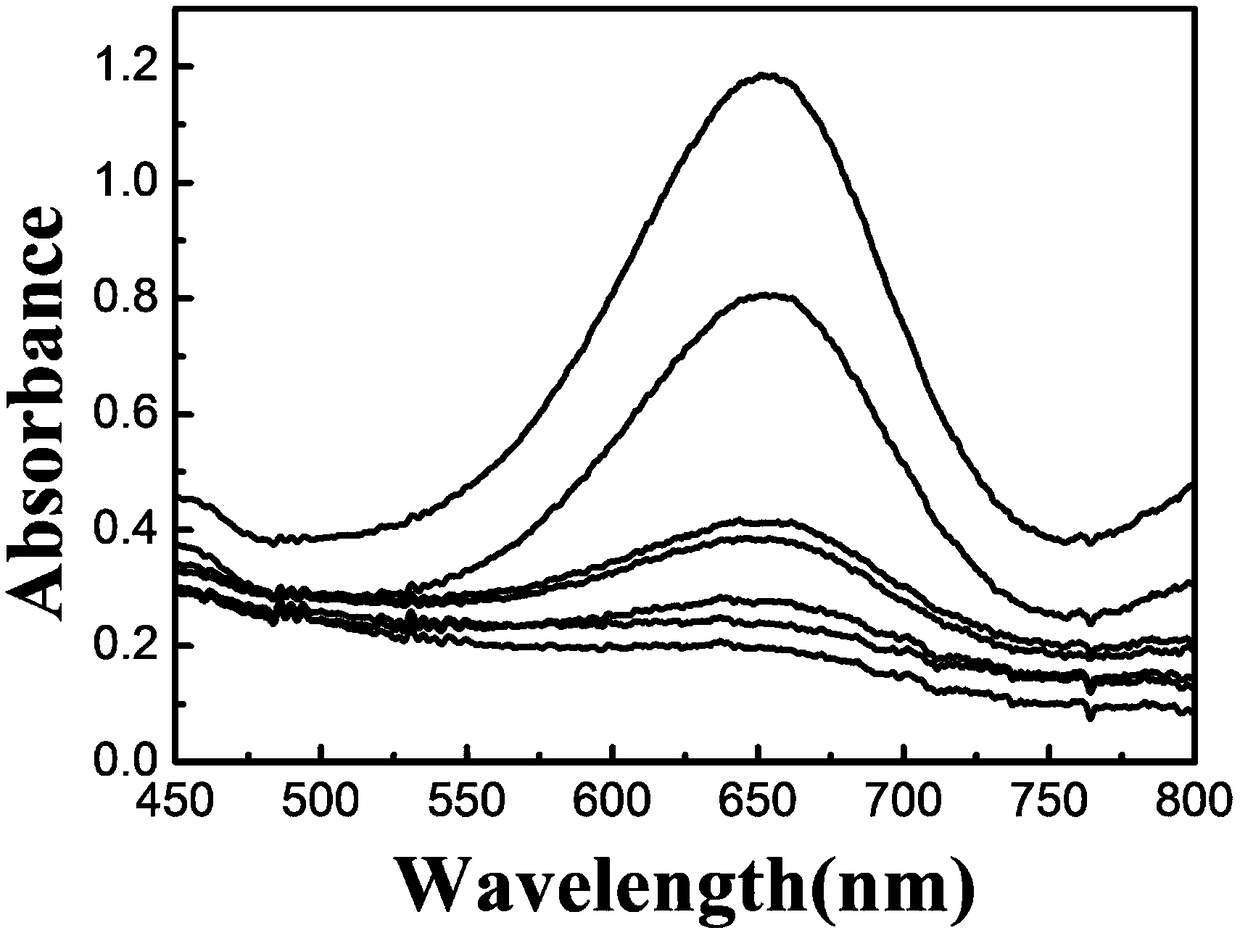

[0046] Step (2), get 50 μ L of Fe prepared in step (1) 3 o 4 -Cu 2+ The simulated enzyme stock solution was added to 1850 μL of 0.1M HAc-NaAc buffer solution (pH=3); then 50 μL of 32 mM 3,3',5,5'-tetramethylbenzidine salt was added to the reaction system Hydrogen peroxide (TMB) was used as the colorimetric reaction substrate; 50 μL of hydrogen peroxide solution with concentrations of 0.2mM, 0.3mM, 0.4mM, 0.6mM, 1mM, 2mM, and 3mM was added, and incubated at 45°C for 35 minutes to obtain a concentration of 5μM, 7.5μM, 10μM, 15μM, 25μM, 50μM, 75μM hydrogen peroxide solution;

[0047] Step (3), get the absorbance value of known hydrogen peroxide concentration solution tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com