Preparation method of calcium silicate hydrate nano film

A hydrated calcium silicate, nano-film technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of lack of microscopic analysis of macroscopic properties, complex structure, etc., and achieve a universal method. The effect of good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

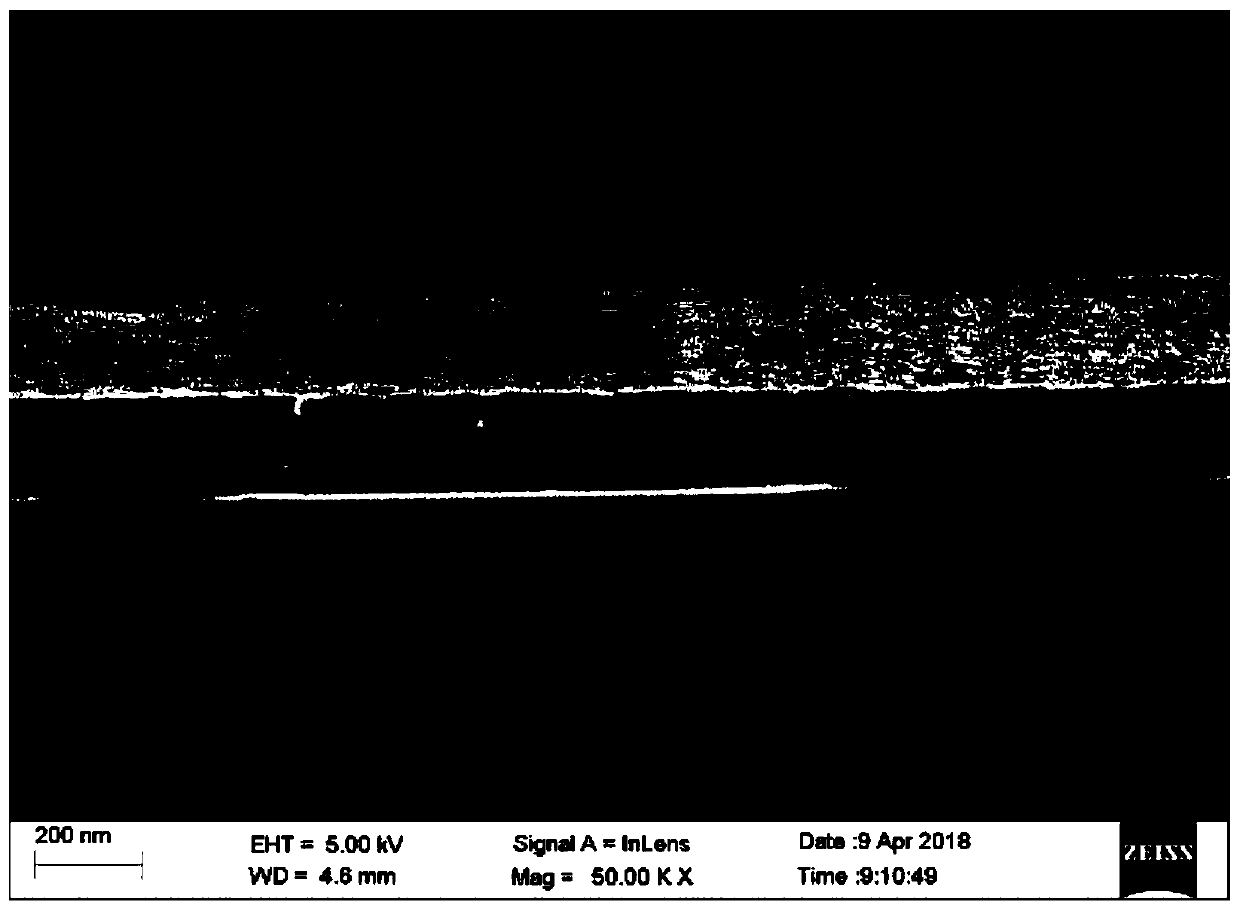

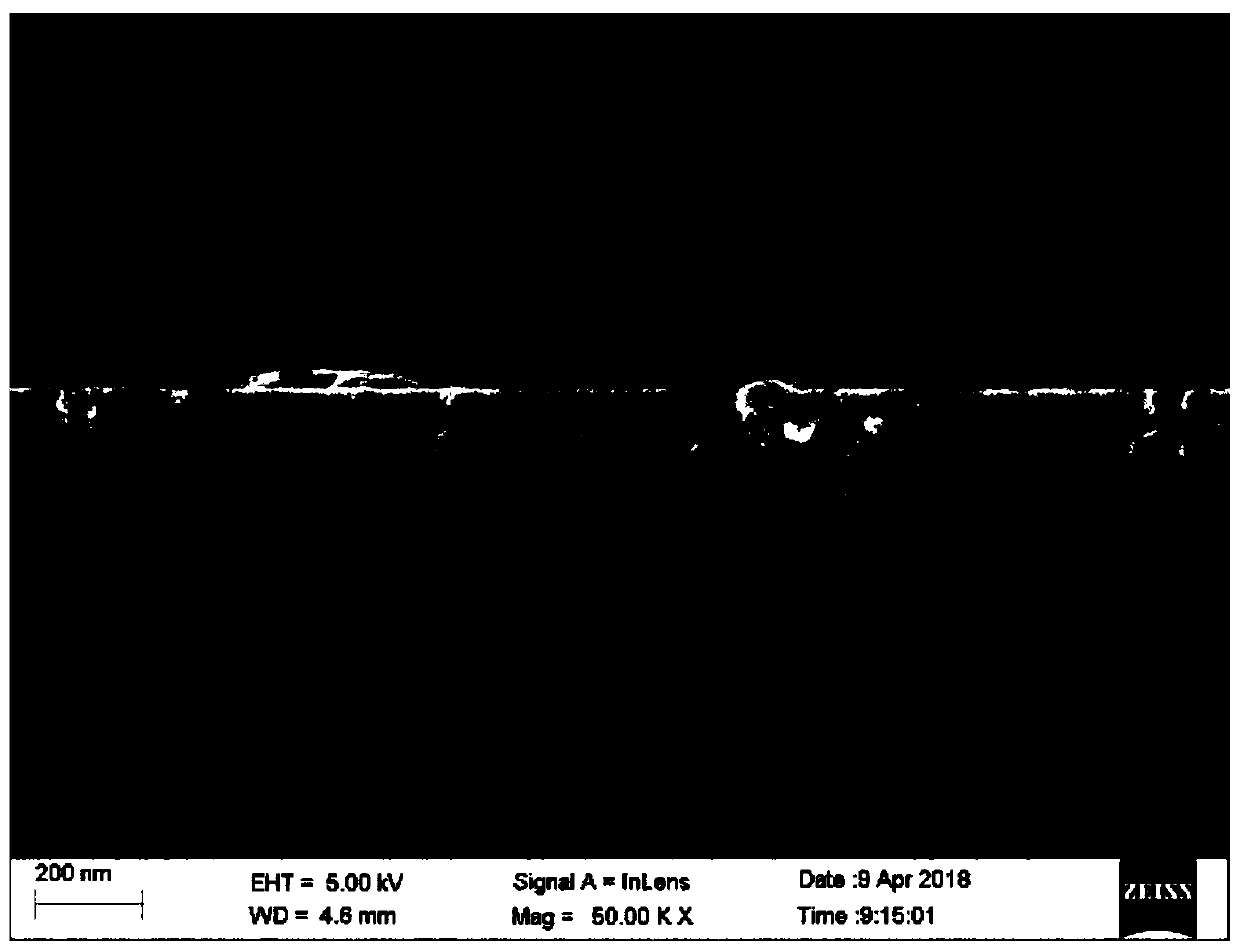

Image

Examples

Embodiment 1

[0030] The present embodiment utilizes magnetron sputtering method to prepare the method for hydrated calcium silicate nano film, carries out according to the following steps:

[0031] (1) the calcium silicate hydrate powder that synthetic calcium silicon ratio is 0.5;

[0032] (2) Calcining the synthesized calcium silicate hydrate powder at 150° C. for 2 hours, and cooling to room temperature;

[0033] (3) Press the calcined powder with a pressure of 100 MPa to obtain a target with a diameter of 60 mm and a thickness of 4 mm;

[0034] (4) The glass sheet is placed on the coating sample stage of the magnetron sputtering apparatus as the substrate, the target is placed in the magnetron target position, and the distance between the substrate and the target is adjusted to 2cm;

[0035] (5) Vacuum the coating chamber and control the vacuum degree to 5×10 -4 Pa;

[0036] (6) feed argon into the coating chamber, control the flow rate of the inert gas to be 10sccm, and control the...

Embodiment 2

[0041] The present embodiment utilizes magnetron sputtering method to prepare the method for hydrated calcium silicate nano film, carries out according to the following steps:

[0042] (1) the calcium silicate hydrate powder that synthetic calcium silicon ratio is 1.5;

[0043] (2) Calcining the synthesized calcium silicate hydrate powder at 175°C for 2.5h, and cooling to room temperature;

[0044] (3) Press the calcined powder with a pressure of 200 MPa to obtain a target with a diameter of 60 mm and a thickness of 5 mm;

[0045] (4) The glass sheet is placed on the coating sample stage of the magnetron sputtering apparatus as the substrate, the target is placed in the magnetron target position, and the distance between the substrate and the target is adjusted to be 4cm;

[0046] (5) Vacuum the coating chamber and control the vacuum degree to 5×10 -4 Pa;

[0047] (6) feed argon into the coating chamber, control the flow rate of the inert gas to be 20sccm, and control the c...

Embodiment 3

[0052] The present embodiment utilizes magnetron sputtering method to prepare the method for hydrated calcium silicate nano film, carries out according to the following steps:

[0053] (1) the calcium silicate hydrate powder that synthetic calcium silicon ratio is 2.0;

[0054] (2) Calcining the synthesized calcium silicate hydrate powder at 200°C for 2.5h, and cooling to room temperature;

[0055] (3) Press the calcined powder with a pressure of 150 MPa to obtain a target with a diameter of 60 mm and a thickness of 5 mm;

[0056] (4) The glass sheet is placed on the coating sample stage of the magnetron sputtering apparatus as the substrate, the target is placed in the magnetron target position, and the distance between the substrate and the target is adjusted to be 5cm;

[0057] (5) Vacuum the coating chamber and control the vacuum degree to 1.0×10 -3 Pa;

[0058] (6) feed krypton gas into the coating chamber, control the flow rate of the inert gas to be 50sccm, and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com