Self-crosslinking silicon-boron-containing high polymer matrix ablation-resistant heat insulation material and preparation method

A technology of thermal insulation material and ablation resistance, which is applied in the field of polymer composite material preparation, and achieves the effect of good compatibility, wide application range, and improvement of ablation resistance and thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

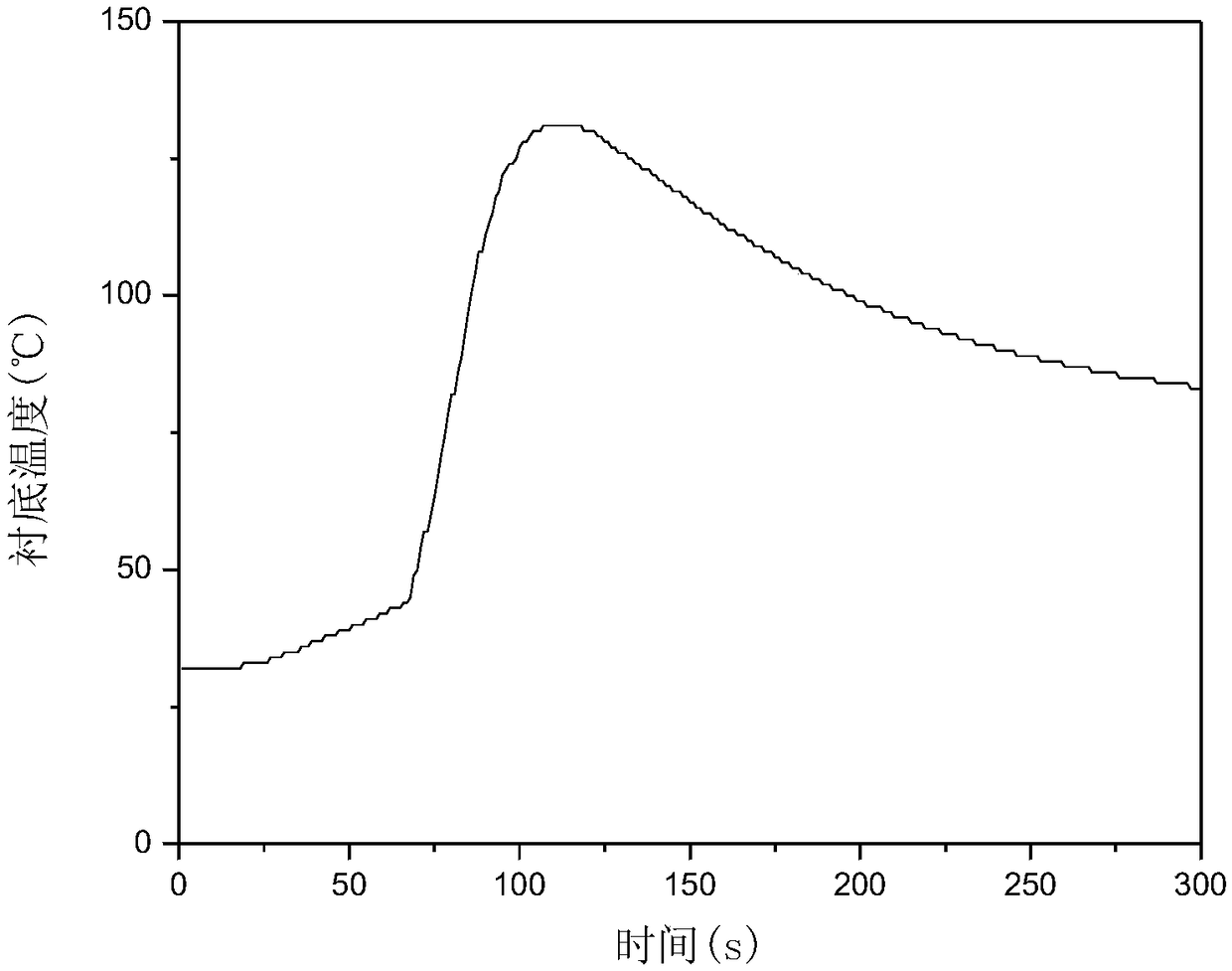

Image

Examples

Embodiment 1

[0040] A self-crosslinking silicon-boron polymer-based ablation-resistant thermal insulation material, the components of which include: 70 parts by mass of methyl vinyl silicone rubber, 30 parts by mass of methylphenyl vinyl silicone rubber, polyborosiloxane 20 parts by mass of prepolymer, 20 parts by mass of white carbon black, 10 parts by mass of carbon fiber of 6 mm, 10 parts by mass of hollow glass microspheres with a particle size of 500 μm, 4 parts by mass of dicumyl peroxide, and 2 parts by mass of hydroxyl silicone oil.

[0041] A method for preparing a self-crosslinking silicon-containing boron polymer-based ablation-resistant thermal insulation material, comprising the following steps:

[0042] Step 1: Crush the ingredients

[0043] According to the ratio, weigh the raw materials, place the polyborosiloxane prepolymer and light ablation-resistant filler in a high-speed pulverizer to disperse and mix evenly to obtain a mixture;

[0044] Step 2: Open refining

[0045...

Embodiment 2

[0051] A self-crosslinking silicon-boron high polymer-based ablation-resistant thermal insulation material, the components of which include: 50 parts by mass of methyl vinyl silicone rubber, 50 parts by mass of methylphenyl vinyl silicone rubber, polyborosiloxane 10 parts by mass of prepolymer, 30 parts by mass of white carbon black, 10 parts by mass of glass fiber with a length of 3 mm, 10 parts by mass of hollow silica with a particle size of 200 μm, 3 parts by mass of dicumyl peroxide, and 3 parts by mass of hydroxyl silicone oil .

[0052] A method for preparing a self-crosslinking silicon-containing boron polymer-based ablation-resistant thermal insulation material, comprising the following steps:

[0053] Step 1: Crush the ingredients

[0054] According to the proportion, weigh the raw materials, place the polyborosiloxane prepolymer and the hollow silica with a particle size of 200 μm in a high-speed pulverizer, disperse and mix evenly, and obtain a mixture;

[0055] ...

Embodiment 3

[0062] A self-crosslinking silicon-boron high polymer-based ablation-resistant thermal insulation material, the components of which include: 60 parts by mass of methyl vinyl silicone rubber, 40 parts by mass of methylphenyl vinyl silicone rubber, polyborosiloxane 25 parts by mass of prepolymer, 20 parts by mass of white carbon black, 8 parts by mass of aramid fibers with a length of 6 mm, 10 parts by mass of hollow aluminum oxide with a particle size of 300 μm, 5 parts by mass of dicumyl peroxide, and 2 parts by mass of hydroxyl silicone oil share.

[0063] A method for preparing a self-crosslinking silicon-containing boron polymer-based ablation-resistant thermal insulation material comprises the following steps:

[0064] Step 1: Crush the ingredients

[0065] According to the ratio, weigh the raw materials, put the polyborosiloxane prepolymer and hollow alumina with a particle size of 300 μm in a high-speed pulverizer, disperse and mix them evenly, and obtain a mixture;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com