Plastic track thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and plastic track technology, applied in the field of thermoplastic elastomers, can solve the problems of hot hole, burnout, plastic track damage, etc., and achieve the effects of enhancing weather resistance, prolonging service life, and enhancing high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

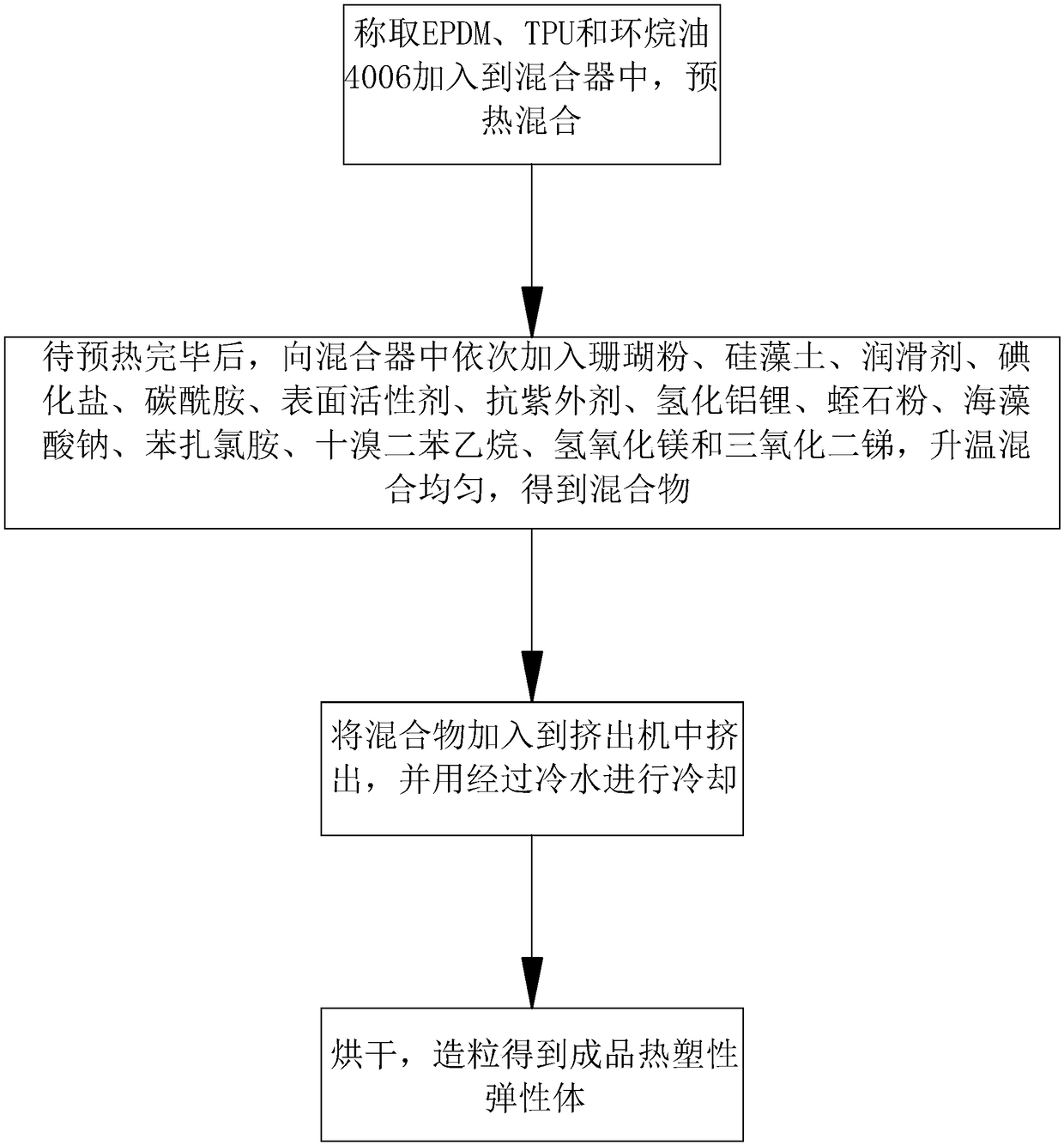

[0039] A preparation method of a thermoplastic elastomer for a plastic runway, mainly comprising the following steps:

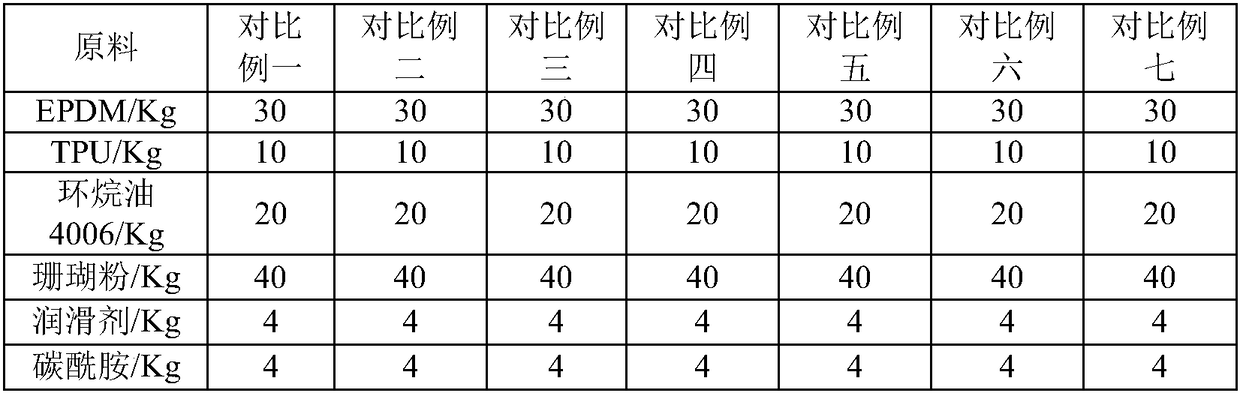

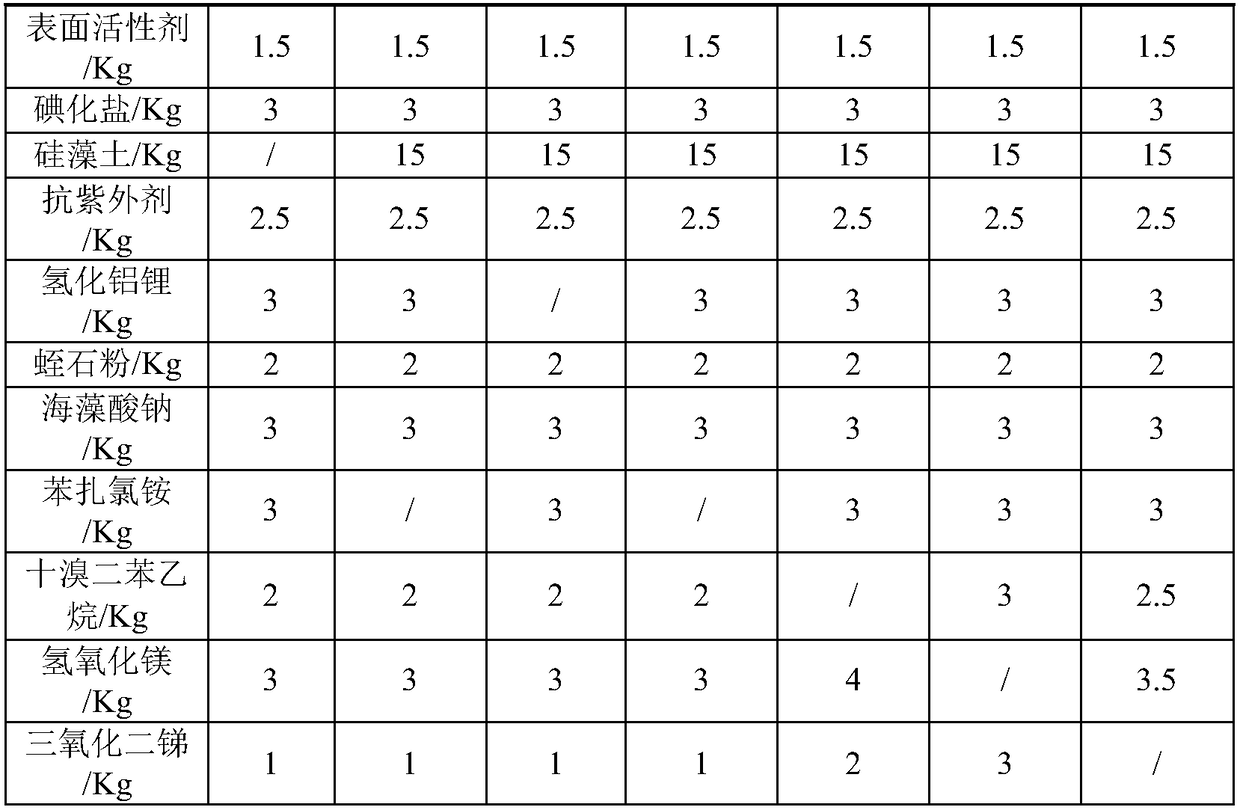

[0040] Step 1. Weigh 25Kg EPDM, 7Kg TPU and 18Kg naphthenic oil 4006 into the mixer, and preheat it to 110°C with 200GHz microwave, and the mixer rotates at a speed of 60rpm under the microwave environment, and keep it for 2h;

[0041]Step 2. After the preheating of step 1 is completed, add 13Kg of coral powder, 14Kg of diatomaceous earth, 3Kg of lubricant, 2Kg of iodized salt, 3Kg of carbonamide, 1Kg of surfactant, and 2Kg of anti-ultraviolet into the mixer. agent, 2Kg lithium aluminum hydride, 1Kg vermiculite powder, 2Kg sodium alginate, 2Kg benzalkonium chloride, 1Kg decabromodiphenylethane, 2Kg magnesium hydroxide and 0.5Kg antimony trioxide, raise the temperature to 130°C and stir The paddle stirs the material evenly, and after 1 hour, the mixture is obtained;

[0042] Step 3. Add the mixture in step 2 to the extruder to extrude thermoplastic elastomer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com