Non-woven fabric with excellent antibacterial performance and manufacturing method of non-woven fabric

A manufacturing method and non-woven technology, applied in rayon manufacturing, textile and papermaking, sustainable manufacturing/processing, etc., can solve the problems of long-term antibacterial, short antibacterial retention time, and disappearance of antibacterial effect. , to achieve good antibacterial effect, improve antibacterial effect and antibacterial time, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

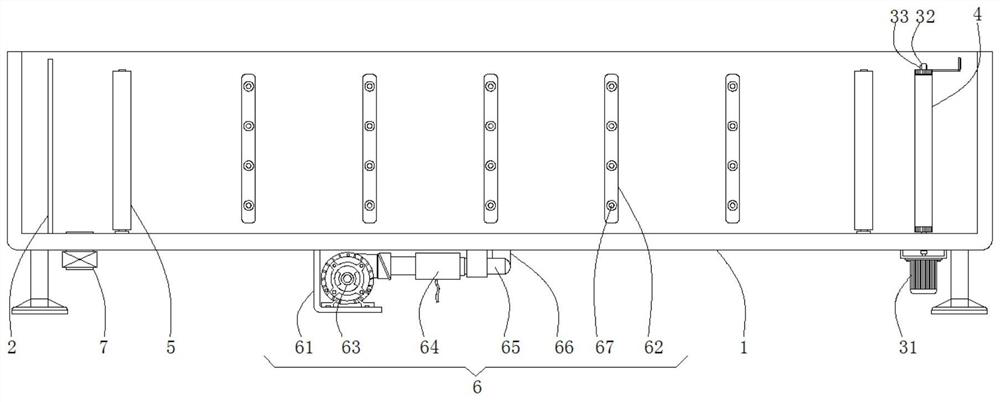

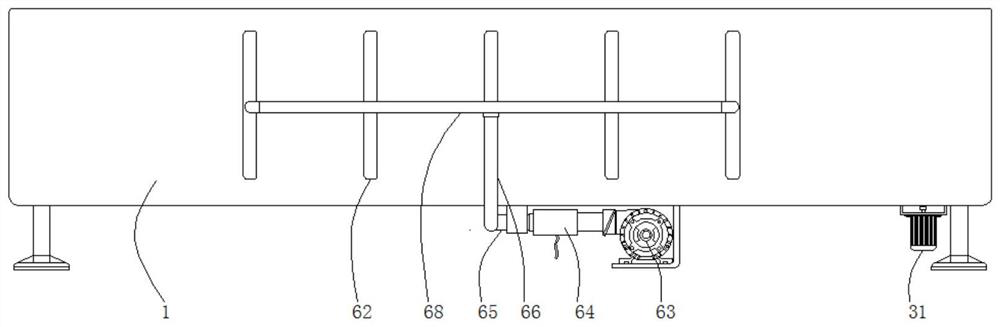

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] A kind of non-woven fabric with excellent antibacterial performance provided by the present invention, it adopts the polypropylene of 60-80 weight part, the polyethylene terephthalate of 20-30 weight part, the silver of 2-4 weight part The ion antibacterial agent, 1-3 parts by weight of bamboo charcoal fiber, 6-8 parts by weight of polyisobutylene and 10-12 parts by weight of reinforcing modifier are prepared according to the ratio of parts by weight.

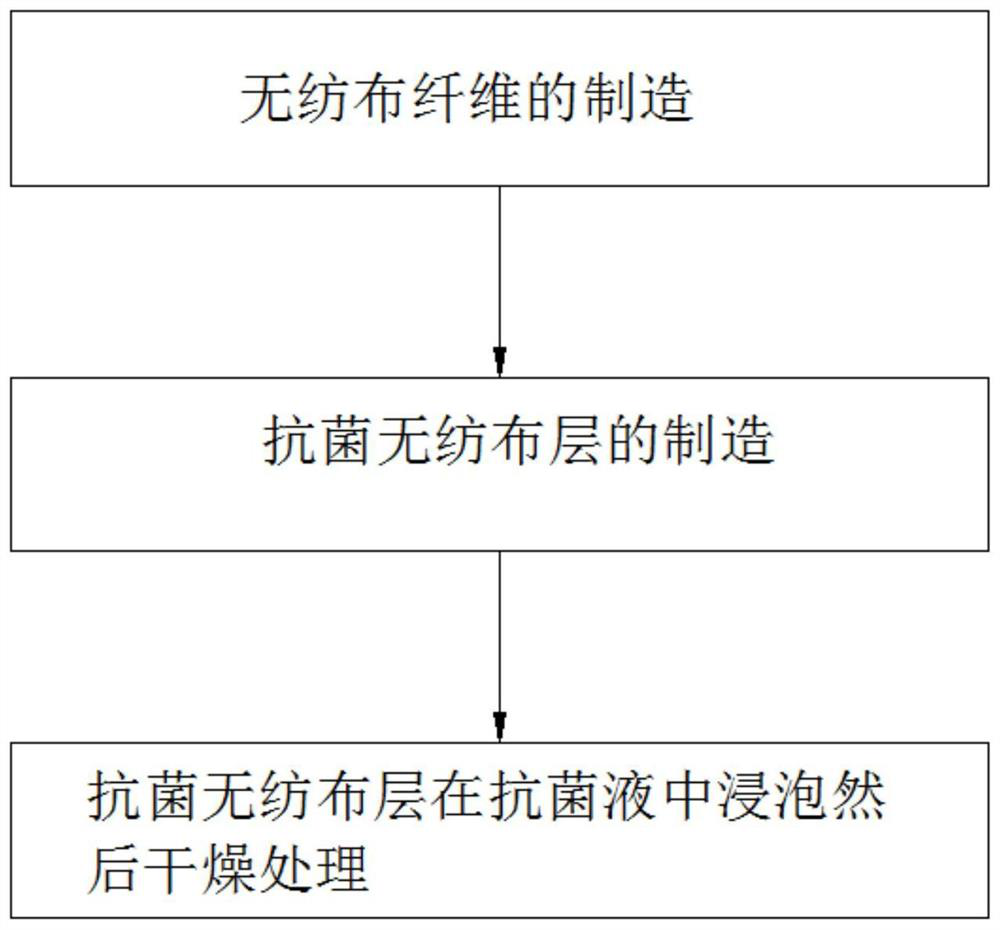

[0034] see figure 1 , the above-mentioned manufacturing method with excellent bacteriostatic property non-woven fabric of proportioning by weight, comprises the steps:

[0035] S1. 60-80 parts by weight of polypropylene, 20-30 parts by weight of polyethylene terephthalate, 6-8 parts by weight of polyisobutylene and 10-12 parts by weight of reinforcing modifiers are put into spinning Machine, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com