A kind of method for hydrogenation of tail gas of dmf method butadiene extraction device

An extraction device and technology for butadiene, which are applied in chemical instruments and methods, hydrogenation to hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as easy polymerization and explosion, and achieve a long operating cycle. , The process is simple, and the effect of ensuring combustion safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

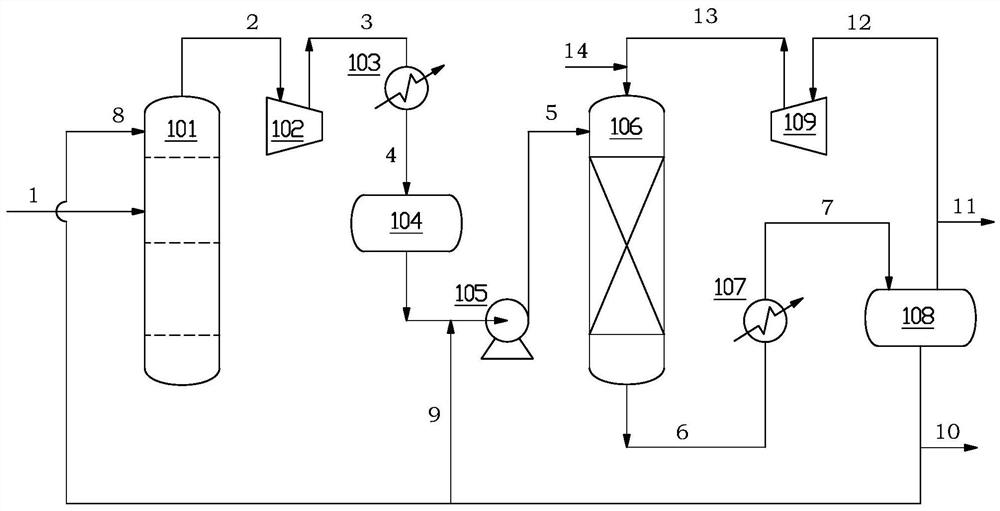

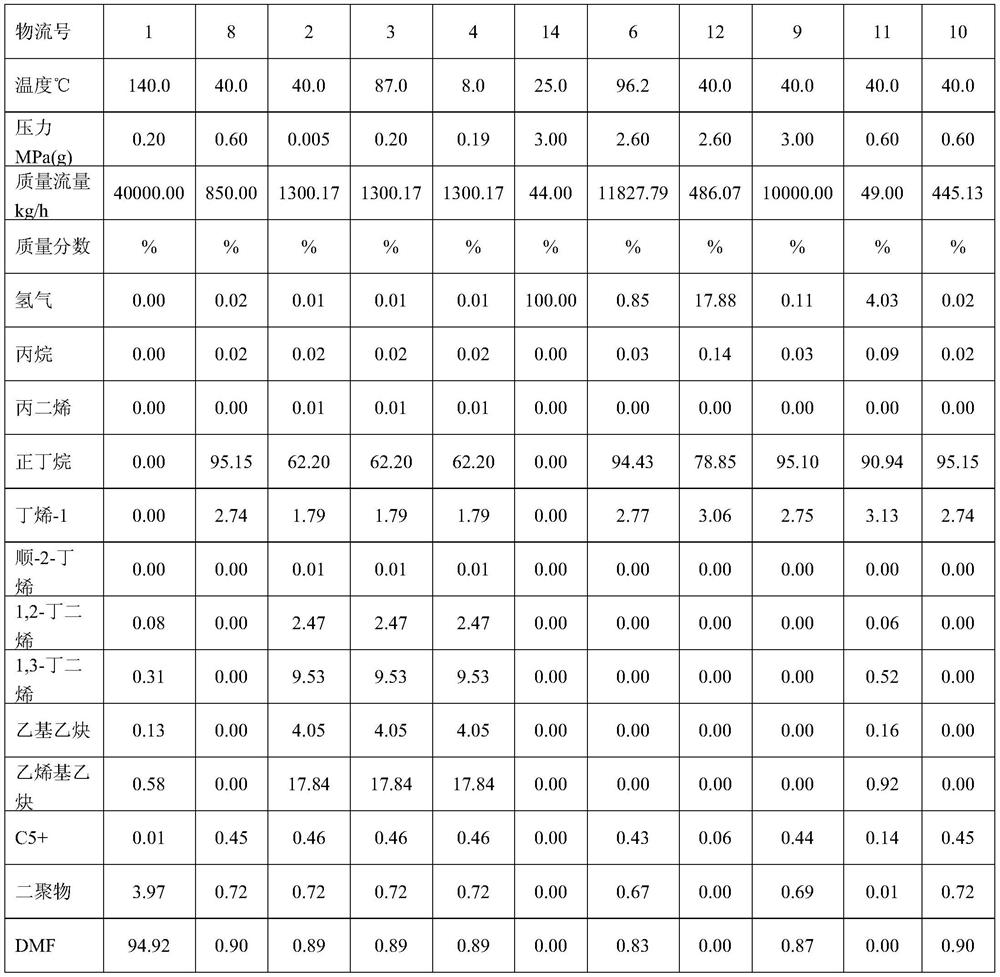

[0038] Dissolved with C 4 The DMF solvent 1 of alkyne enters the middle part of the second stripping tower 101, the total mass flow of DMF solvent 1 is 40000kg / h, and the pressure is 0.2MPaG, and the temperature is 140 ℃, wherein C 4 The mass flow rate of VA (vinyl acetylene) is 440.75kg / h, the mass flow rate of VA (vinyl acetylene) is 231.91kg / h, and the content of VA is 0.58wt%; The theoretical plate number that the second stripper 101 adopts is 10, and the pressure is 0.01 MPaG, the temperature of the tower bottom is 163.4°C. The hydrogenated product C48 from the butadiene tail gas hydrogenation unit enters the top of the second stripper 101 as a diluent, and the mass flow rate of the hydrogenated product C48 used for dilution is 850kg / h, and the hydrogenated product C48 The ratio of the mass flow rate of to the mass flow rate of vinyl acetylene in DMF solvent 1 containing C4 alkyne is 3.67. Dissolved with C 4 The DMF solvent 1 of alkynes comes from the tower still of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com