Green preparation method of high silica-alumina ratio hydrogenous molecular sieve

A hydrogen-type molecular sieve, high silicon-aluminum ratio technology, applied in molecular sieve compounds, molecular sieve characteristic silicates, chemical instruments and methods, etc., can solve the problems of failure of recycling routes, consumption of crystal seeds, enrichment of inorganic salts such as sodium bromide and other issues to achieve the effect of reducing production process steps, saving water and energy consumption, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

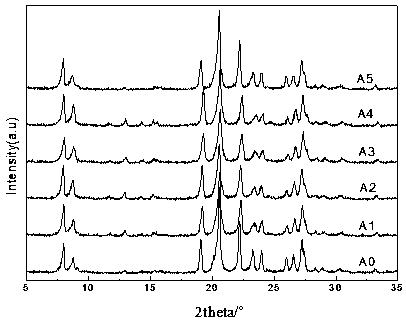

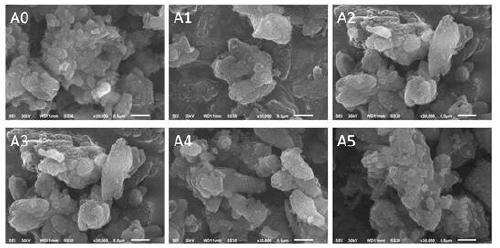

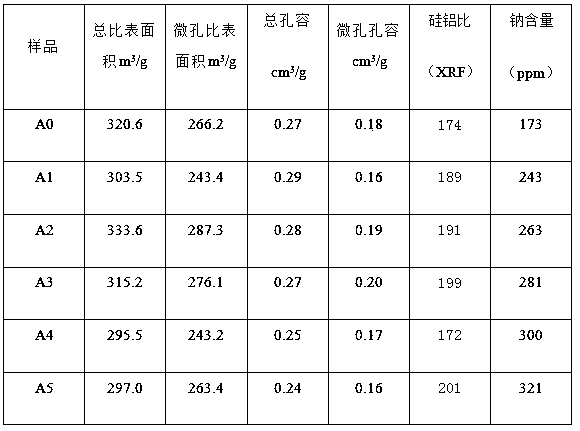

Embodiment 1

[0024] Get 5.8g of deionized water, 10g of 1.02mol / L hexamethyldiammonium hydroxide solution, 6.0g of ammonium-type silica sol, wherein SiO 2 The mass ratio is 30%wt, 0.0136g pseudo-boehmite (Al 2 o 3The mass ratio is 75%wt) and mixed, stirred at room temperature for 1h, installed in a stainless steel reactor, and crystallized at 180°C for 48h. After the crystallization is completed, cool, filter, wash until neutral, and dry to record as A0. The sample is calcined at 400°C for 6 hours to obtain a hydrogen-type EU-1 molecular sieve. Among them, the molecular sieve mother liquor is collected during the suction filtration process, and its hydroxide, silica, and alumina components are analyzed; deionized water, hexamethyldiammonium hydroxide, ammonium-type silica sol, and pseudoboehmite are added in the first cycle. Continue to crystallize after the gel ratio is consistent with the initial feeding. The crystallization temperature time and treatment method are the same as A0, and...

Embodiment 2

[0027] Take 8.0g of deionized water, 10g of hexamethyldiammonium hydroxide solution (0.3mol / L), 6.429g of ethyl orthosilicate (SiO 2 The mass ratio is 28wt%wt), 0.0408g pseudo-boehmite (Al 2 o 3 The mass ratio is 75%wt), mixed at room temperature for 1 hour, installed in a stainless steel reactor, and crystallized at 200°C for 24 hours. After the crystallization is completed, cool, filter with suction, wash until neutral, and dry to record as B0. The sample is calcined at 600°C for 3 hours to obtain a hydrogen-type EU-1 molecular sieve. Among them, the molecular sieve mother liquor is collected during the suction filtration process, and its hydroxide component, silica component, and alumina component are analyzed; deionized water, hexamethyldiammonium hydroxide, ethyl orthosilicate, and pseudoboehmite are added in the first cycle. After the proportion of the stone and the initial feeding gel was consistent, the crystallization continued. The crystallization temperature, time...

Embodiment 3

[0029] Take 0.4g of deionized water, 5.0g of hexamethonium hydroxide solution (3.0mol / L), 1.818g of silica gel (SiO 2 The mass ratio is 99%wt), 0.0272g pseudo-boehmite (Al 2 o 3 The mass ratio is 75%wt), mixed at room temperature for 1 hour, installed in a stainless steel reactor, and crystallized at 200°C for 24 hours. After the crystallization is completed, cool, filter, wash until neutral, and dry to record as C0. The sample is calcined at 600°C for 3 hours to obtain a hydrogen-type EU-1 molecular sieve. Among them, the molecular sieve mother liquor is collected during the suction filtration process, and its hydroxide component, silica component, and alumina component are analyzed; deionized water, hexamethylbisammonium hydroxide, silica gel, pseudoboehmite and initial feeding are added in the first cycle. After the gel ratio is consistent, continue to crystallize. The crystallization temperature, time and processing method are the same as C0, and sample C1 is obtained. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com