A method for forging/additive composite manufacturing of amorphous alloy parts

A technology of amorphous alloy and manufacturing method, which is applied in the field of forging/additive composite manufacturing of amorphous alloy parts, which can solve the problems of poor overall performance, size limitation, poor interface connection performance, etc., achieve fast sintering speed and increase density , the effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

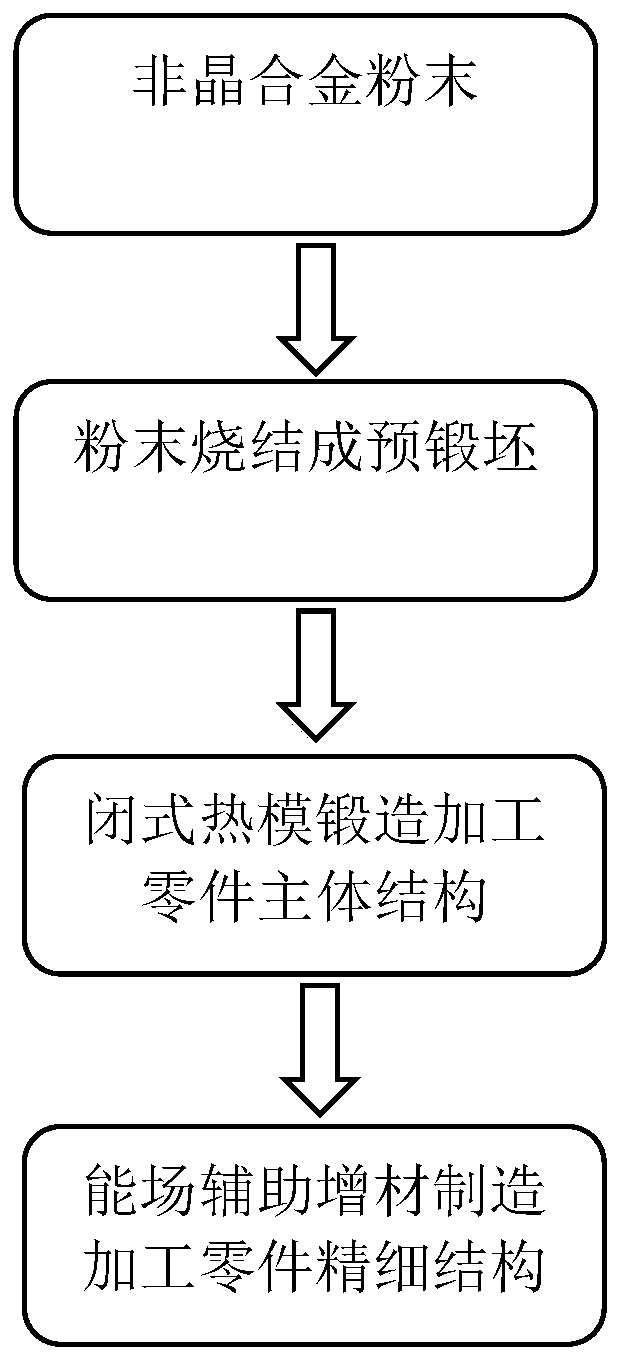

[0063] figure 1 It is a flow chart constructed according to an amorphous alloy part forging / additive composite manufacturing method of the present invention, such as figure 1 As shown, it includes the following steps:

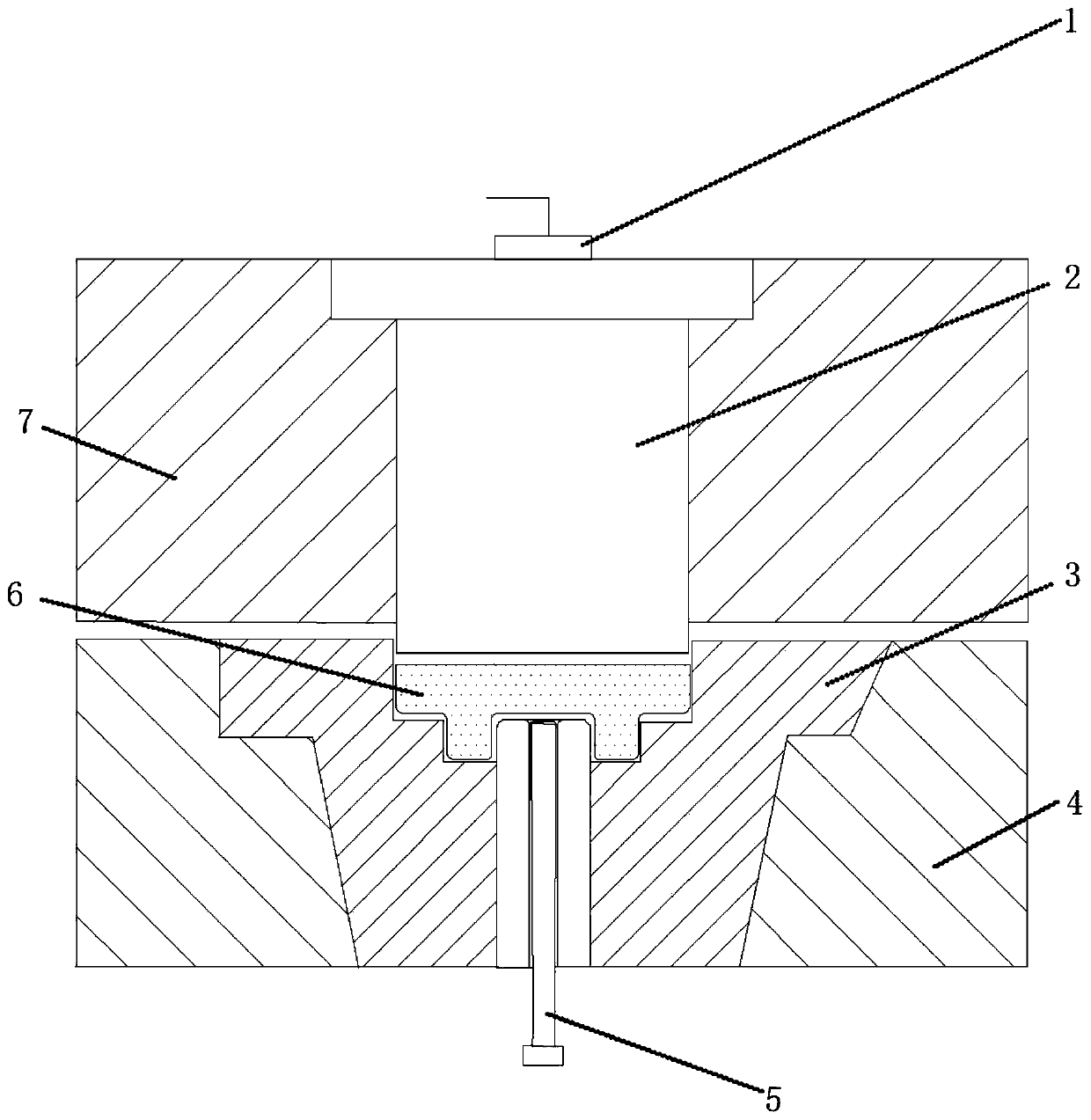

[0064] (1) Choose Zr with a particle size of 35 μm prepared by vacuum induction inert gas atomization technology 55 Cu 25 Al 10 Ni 10 Amorphous alloy powder is made into pre-forged blank. Zr 55 Cu 25 Al 10 Ni 10 The critical dimension of the formation of amorphous alloy is greater than 10mm, and the glass transition temperature T g is 652K, the initial crystallization temperature T x is 757K, the liquidus temperature T L is 1121K, supercooled liquid phase interval ΔT x =T x -T g =105K, thermoplastic forming ability index S=ΔT x / (T L -T g )=0.224, it has good amorphous forming ability. Firstly, put the selected amorphous alloy powder into the sheath, and press it into a cold compact by cold isostatic pressing technology. The material used is ...

Embodiment 2

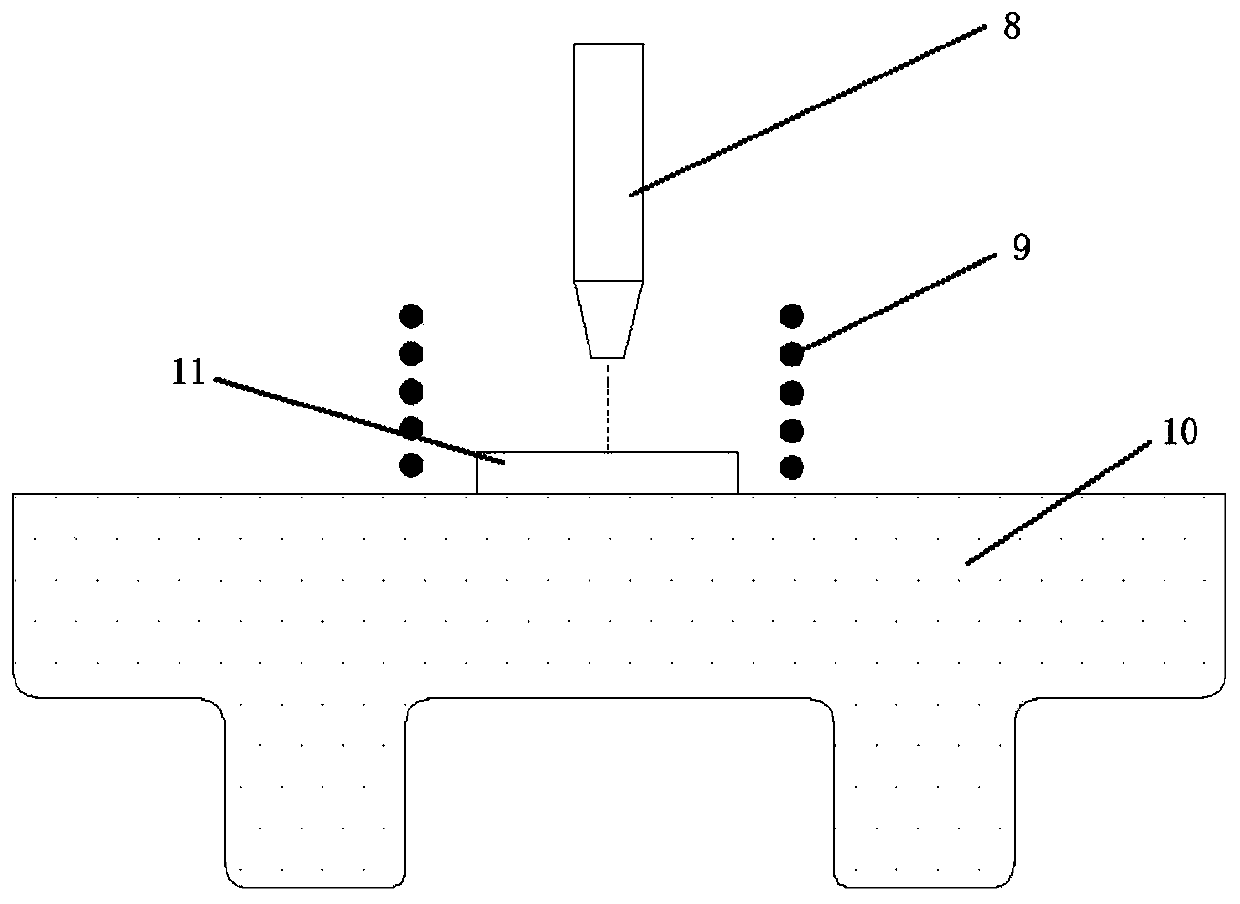

[0069] This embodiment is used to prepare an amorphous part with low internal stress requirements and subjected to alternating loads. When preparing this part, the same method as in Example 1 is used, and the amorphous alloy powder material is first made into a pre-forged billet by using powder sintering technology. , and then put the pre-forged billet in a closed forging die for closed hot die forging to obtain the main structure of the amorphous alloy part. Then, the ultra-high frequency strong pulse square wave assisted arc additive manufacturing technology is used to add materials to the main structure of the part to prepare fine structures.

[0070] Figure 4 It is a principle diagram of an ultra-high frequency strong pulse square wave assisted arc additive manufacturing method constructed according to a preferred embodiment of the present invention. Among them, 12-arc welding torch, 13-wire feeding mechanism, 16-current controller. Different pulse square wave currents ...

Embodiment 3

[0073] This embodiment is used to prepare amorphous parts with higher requirements on mechanical properties. When preparing the parts, the same method as in Example 1 is used to make the pre-forged billet from the amorphous alloy powder material by powder sintering technology, and then the pre-forged billet Place in a closed forging die for closed hot die forging to obtain the main structure of the amorphous alloy part. Then high-frequency micro-hammer forging assisted laser additive manufacturing technology.

[0074] Figure 7 Shown is a schematic diagram of an ultrasonic frequency micro-forging assisted laser additive manufacturing method constructed according to a preferred embodiment of the present invention. Among them, 14-micro-forging head, 15-piezoelectric ceramic vibration generator. First turn on the control power supply, and generate ultrasonic frequency vibration with the help of a piezoelectric ceramic vibration generator. The path of the micro-forging head 14 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com