Graphene/copper composite conductive material and preparation method thereof

A composite conductive and composite material technology, which is applied in the field of graphene/copper composite conductive materials and its preparation, can solve problems such as difficult uniform dispersion, easy agglomeration, and density difference, so as to avoid agglomeration, make the preparation process simple and easy, and maintain topographical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

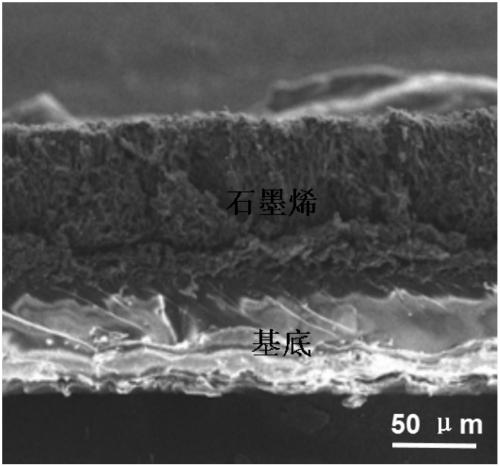

[0036] The invention discloses a preparation method of a graphene / copper composite conductive material, which is used to solve the problem of uniform dispersion of graphene in the composite material. refer to figure 1 , the preparation method of the graphene / copper composite conductive material comprises the following steps.

[0037] (1) Preparation of porous graphene on organic substrates

[0038] One surface of an organic polymer film polyimide with a thickness of 150 μm is exposed to laser irradiation, and CO with a wavelength of 10.6 μm is selected in this embodiment. 2 Infrared laser, the laser power is 5W, the pulse frequency is 20kHz, and the laser scanning speed is 800mm / s. The surface of the polyimide film is carbonized to form porous graphene, and the parts not affected by the laser play a role in supporting the graphene, that is, the porous graphene on the organic substrate is obtained, and its pore structure is as follows: figure 2 As shown, the thickness of po...

Embodiment 2

[0044] The preparation method of the graphene / copper composite conductor material in this embodiment is the same as in Embodiment 1, the laser power used is 4W, and the rest of the conditions are the same as in Embodiment 1. The tensile strength of the prepared composite material is 311Mpa, and the electrical conductivity is 96%IACS.

Embodiment 3

[0046] The preparation method of the graphene / copper composite conductor material of this embodiment is the same as that of embodiment 1, and the electroplating time used is 15min, and all the other conditions are the same as that of embodiment 1. The tensile strength of the prepared composite material is 334Mpa, and the electrical conductivity is 88%IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com