A kind of graphene/aluminum composite conductive material and preparation method thereof

A technology of aluminum composite materials and conductive materials, applied in the direction of graphene, cable/conductor manufacturing, metal/alloy conductors, etc., can solve problems such as difficulty in uniform dispersion, easy agglomeration, and density difference, so as to avoid agglomeration and enhance mechanical properties and conductivity, to ensure the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The invention provides a method for preparing a graphene / aluminum composite conductive material, which can solve the technical problem of uniform dispersion of graphene in the composite material, thereby achieving optimal mechanical properties and electrical conductivity.

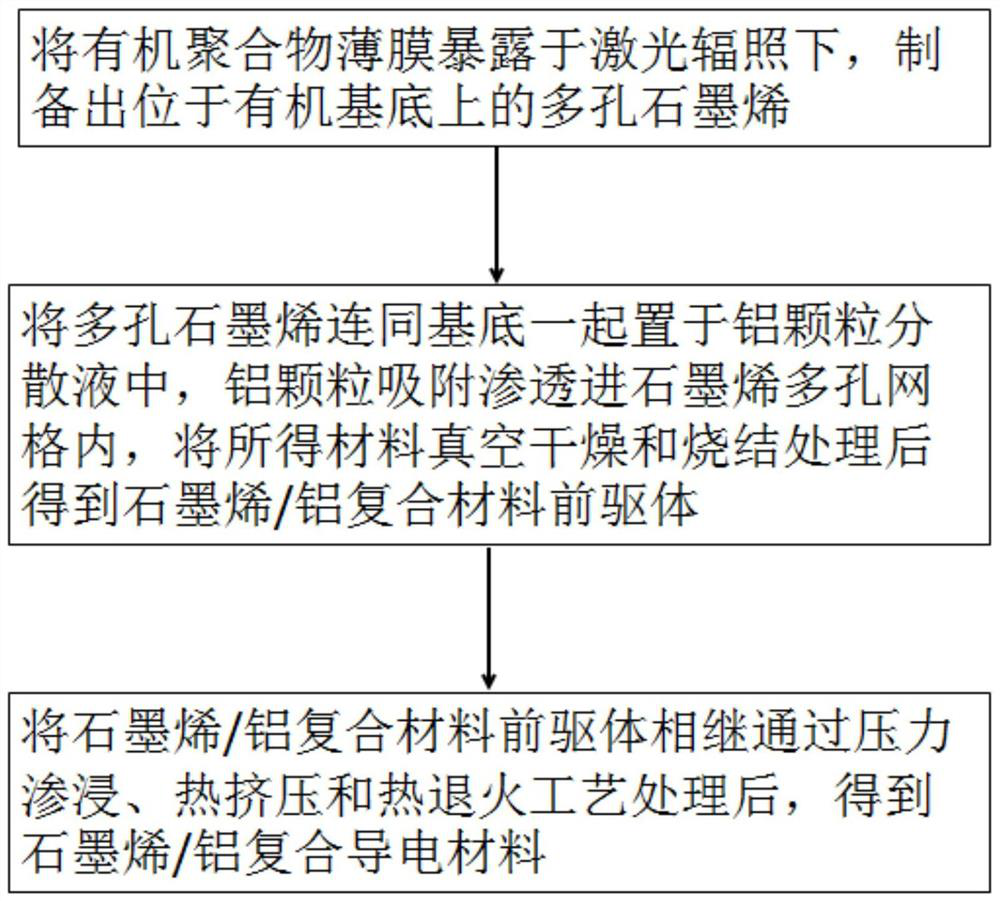

[0040]The preparation method of graphene / aluminum composite conductive material includes the following steps:

[0041](1) Preparation of porous graphene on organic substrates

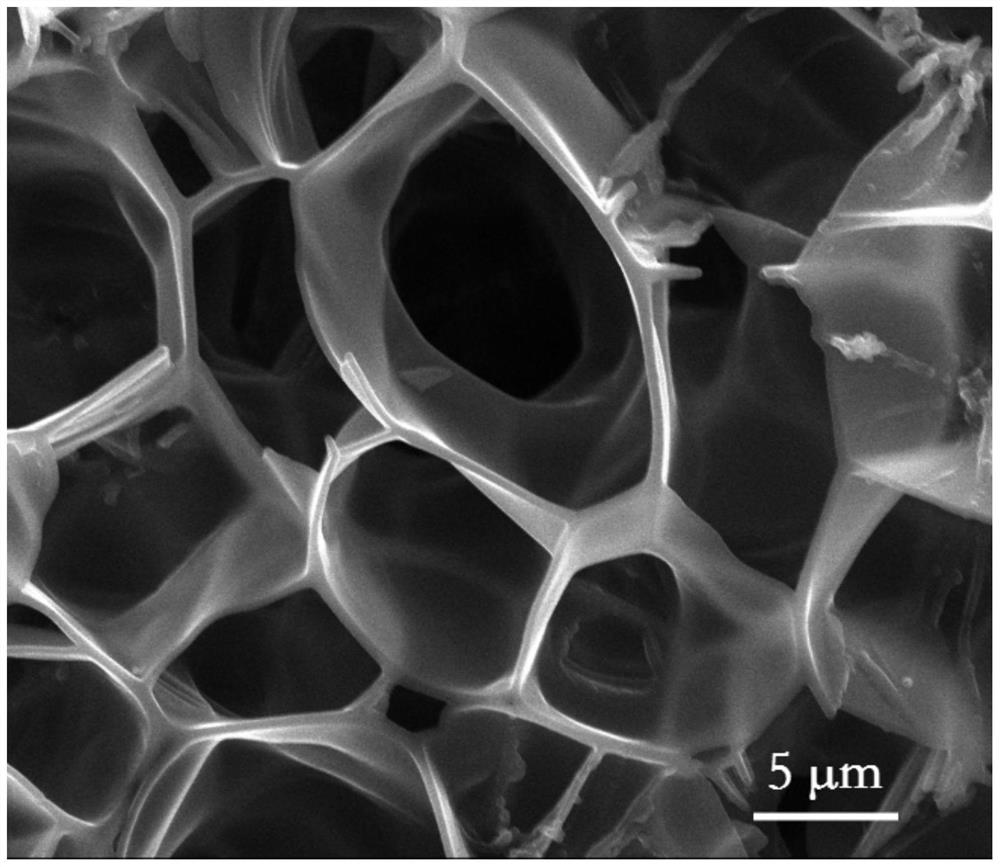

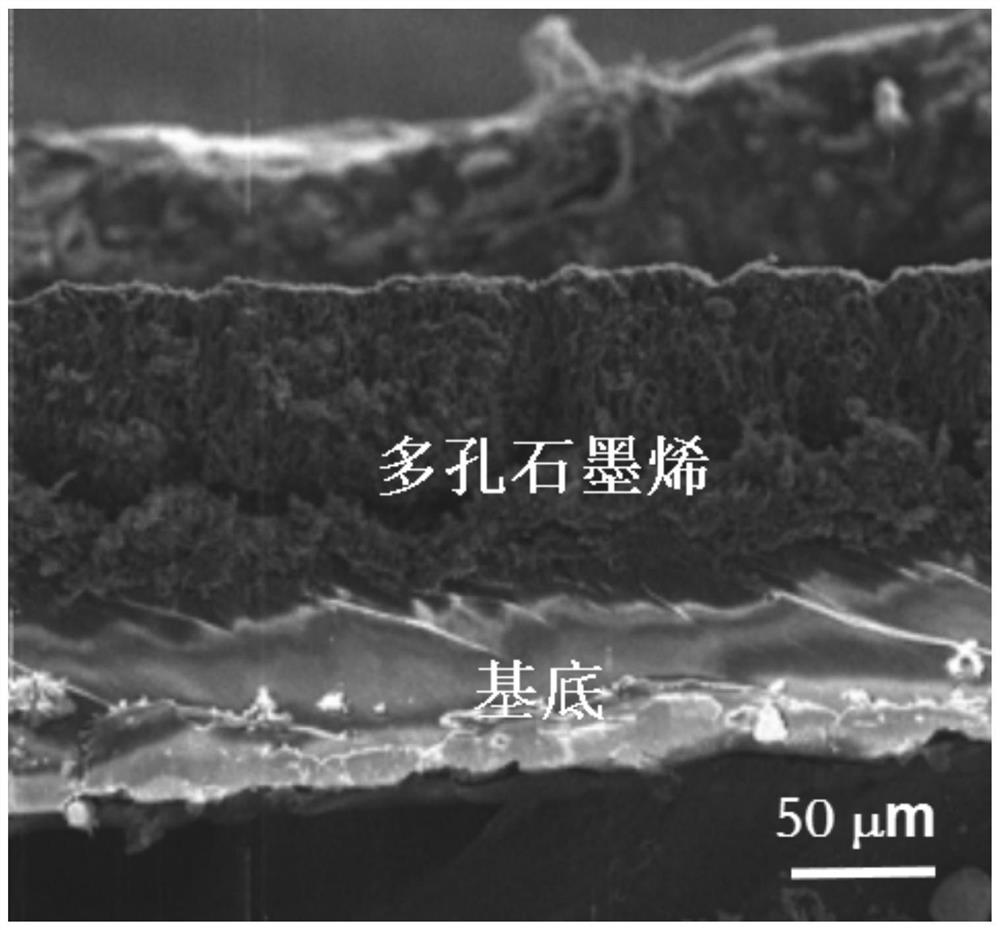

[0042]Expose one surface of an organic polymer film polyimide with a thickness of 150um to laser radiation, the laser is selected as CO with a wavelength of 10.6μm2Infrared laser, laser power is 5W, pulse frequency is 20kHz, laser scanning speed is 800mm / s. The surface of the polyimide film is carbonized to form porous graphene, that is, porous graphene on an organic substrate is obtained, and the pore structure is asfigure 2 As shown, the thickness of porous graphene is 100 microns, such asimage 3 As shown, the Raman spectrum of porous graph...

Embodiment 2

[0049]The preparation method of the graphene / aluminum composite conductor material in this embodiment is the same as that in Embodiment 1, the laser power used is 4W, and the other conditions are the same as in Embodiment 1. The tensile strength of the prepared composite material is 293Mpa, and the electrical conductivity is 60% IACS.

Embodiment 3

[0051]The preparation method of the graphene / aluminum composite conductor material in this example is the same as that in Example 1, the aluminum powder particle size used is an average of 10 μm, and the other conditions are the same as in Example 1. The tensile strength of the prepared composite material is 315Mpa, and the conductivity is 68% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com