Photochromic room temperature magnetic semiconductor material and preparation method thereof

A magnetic semiconductor and photochromic technology, which is applied in the direction of color-changing fluorescent materials, luminescent materials, and the magnetism of inorganic materials, to achieve the effects of fast photochromic rate, enhanced magnetic response, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

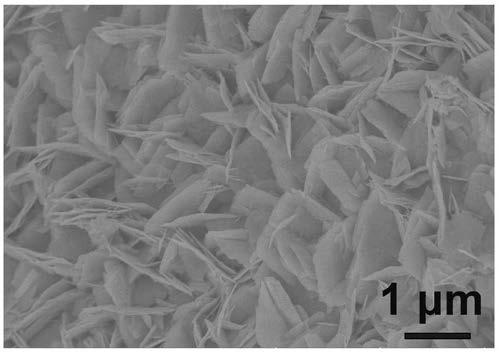

Image

Examples

Embodiment 1

[0049] A method for preparing a photochromic room temperature magnetic semiconductor material, the steps are as follows:

[0050] (1) Preparation of precursor solution

[0051] Add 0.5g of bismuth nitrate pentahydrate into 0.8mol / L nitric acid solution, stir until bismuth nitrate pentahydrate is completely dissolved, then add 0.18g of sodium tungstate, stir for about 10 minutes, then add 0.3g of polyethylene glycol;

[0052] (2) Hydrothermal reaction

[0053] Pour the mixed solution obtained in step (1) into a 50ml polytetrafluoroethylene reactor for hydrothermal reaction, the reaction conditions are: temperature: 180°C, reaction time: 6 hours. The reactor was taken out and cooled to room temperature naturally.

[0054] (3) Product post-processing

[0055] The hydrothermal reaction mixed solution obtained in step (2) was centrifuged and washed three times with deionized water at a centrifugal speed of 8000rmp; then, the product obtained by the centrifugation was dried in an...

Embodiment 2

[0059] A method for preparing a photochromic room temperature magnetic semiconductor material, the steps are as follows:

[0060] (1) Preparation of precursor solution

[0061] Add 0.5g of bismuth nitrate pentahydrate into 0.8mol / L nitric acid solution, stir until bismuth nitrate pentahydrate is completely dissolved, then add 0.18g of sodium tungstate, stir for about 10 minutes, then add 0.3g of polyethylene glycol;

[0062] (2) Hydrothermal reaction

[0063] Pour the mixed solution obtained in step (1) into a 50ml polytetrafluoroethylene reactor for hydrothermal reaction. The reaction conditions are: temperature: 180°C, reaction time: 10 hours, take out the reactor and naturally cool to room temperature.

[0064] (3) Product post-processing

[0065] The hydrothermal reaction mixed solution obtained in step (2) was centrifuged and washed three times with deionized water at a speed of 8000 rpm; then, the product obtained by the centrifugation was dried in an oven at 80 degree...

Embodiment 3

[0069] A method for preparing a photochromic room temperature magnetic semiconductor material, the steps are as follows:

[0070] (1) Preparation of precursor solution

[0071] Add 0.5g of bismuth nitrate pentahydrate into 0.8mol / L nitric acid solution, stir until bismuth nitrate pentahydrate is completely dissolved, then add 0.18g of sodium tungstate, stir for about 10 minutes, then add 0.3g of polyethylene glycol;

[0072] (2) Hydrothermal reaction

[0073] Pour the mixed solution obtained in step (1) into a 50ml polytetrafluoroethylene reactor for hydrothermal reaction, the reaction conditions are: temperature: 180°C, reaction time: 17 hours. The reactor was taken out and cooled to room temperature naturally.

[0074] (3) Product post-processing

[0075] The hydrothermal reaction mixed solution obtained in step (2) was centrifuged and washed three times with deionized water at a speed of 8000 rpm; then, the product obtained by the centrifugation was dried in an oven at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com